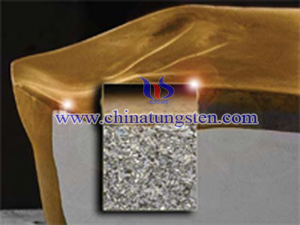

Tungsten Carbide Inserts Coating Architecture for Turning Operation (1)

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 June 2015 15:07

In actual practice, when employing coated tungsten carbide inserts on turning operations, there are several typical factors are likely to be involved, such as huge strains, high interface temperature, and newly generated chemically reactive surface. Specially, the interface temperature between tool and chip or tool and workpiece could be leveled up to 700-1250 ℃ and in the cutting zone the energy consumption due to the frictional losses varied from 25-35%.

In order to withstand such harsh condition, an ideal coating architecture of tungsten carbide inserts is required to meet high wear resistance, outstanding chemical stability, hot hardness, low friction and excellent adhesion to the substrate, as well as compressive residual stresses.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com