Blue Tungsten Oxide Cyclic Oxidation Producing Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 18:30

Fine tungsten powder is an important raw material for producing tungsten carbide powder, to improve the performance of carbide tungsten is necessary to reduce or eliminate the coarse tungsten powder particles. Otherwise it will cause tungsten carbide cracks, fracture and other phenomena in the course. After studies the process of using blue tungsten oxide as raw material to produce fine tungsten powder research found that by using exceptionally pure ammonium paratungstate calcinate in ammonia to get blue tungsten and then go through the cyclic oxidation producing fine tungsten powder, and the tungsten powder properties is better which is less coarse. Producing process as follows:

1. Slow heating exceptionally pure ammonium paratungstate which is in ammonia to 600 ℃, when the temperature reach 600℃for 10min heat preservation to produce blue tungsten oxide.

2. To obtain tungsten powder by restoring blue tungsten oxide in hydrogen.

3. The obtained tungsten powder slowly heating in air to 500 ℃, for the first time oxidation. When the temperature reaches 500 ℃ for 10min heating preservation to obtain tungsten trioxide.

4. The obtained tungsten trioxide in the hydrogen condition to process second reduction.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Quality Requirement of Using Blue Tungsten Oxide To Produce Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 18:29

Fine tungsten powder is widely used in various fields, but the manufacturing process conditions and material requirements it is very rigorous. Using blue tungsten oxide as raw materials to produce ultrafine tungsten powder also has certain material quality requirements which are including blue tungsten impurity content, particle size and volatiles requirements.

Firstly, blue tungsten impurity content requirement, purity and impurities of blue tungsten oxide will influence the tungsten powder grain size and quality directly. Selecting high-quality blue tungsten is the important factor for producing good performance and fine tungsten powder which is an important part in producing fine tungsten oxide process.

Since impurities can be a carrier of oxygen which will delay the residence time of oxygen in the powder layer, to promote the chemical vapor transport can lead to grow tungsten powder particles. The influence of particle size of blue tungsten oxide is when the fee's size from 7.90um increase to 12.94um, tungsten powder particle size reduced from 1.17um to 0.99um, which shows coarse particles of blue tungsten oxide is more advantageous for the preparation of fine tungsten powder. Finally, blue tungsten oxide volatiles requirements, blue tungsten oxide has different residual volatile matter such as NH3 and H2O which will make hydrogen humidity increases in the furnace and it is bad for the preparation of fine tungsten powder.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Reduction Process Fromγ-Tungsten Oxide To Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 18:27

The process of blue tungsten oxide restore to tungsten powder that the primary phase composition is β- tungsten oxide (WO2.9), γ- tungsten oxide (WO2.72), tungsten dioxide (WO2) and tungsten powder in this process. During reduction process which is from blue tungsten to γ-tungsten oxide, γ- tungsten oxide particle surface becomes rougher, rod-shaped and needle-like shape and irregular arrangement. This form is conduct to facilitate the reaction and to obtain fine tungsten powder. With the further reduction the γ- tungsten oxide transformed into tungsten oxide, and tungsten dioxide particles become denser, shaped like tungsten powder particle morphology. In this process, if works can control the process conditions well, may be can preparing fine or ultrafine tungsten powder by γ- tungsten oxide. In the final stage reduction process of tungsten powder, tungsten dioxide reduction to tungsten powders and the morphology of tungsten powder which is not very different with tungsten dioxide. Where is a tungsten dioxide grains turn into a tungsten powder grains. Therefore, the morphology changing is mainly prior to tungsten dioxide generated. In order to produce good performance and fine tungsten powder well control the technology conditions before generated tungsten dioxide is very important.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Test Method of Tungsten Contacts in Cut-out

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 18:26

Weld strength is measured according to the regulations in JB / T 9864.2 ------ 1999.

Check and measurement of tungsten contacts is available by using universal measuring tool.

Tungsten contacts appearance and weld can be checked with a magnifying glass or by visual inspection.

Determination of the number of sections of crystal grains according to GB / T 4197 requirements.

The roughness of contact surface of tungsten contacts can be measured with surface roughness measuring instrument.

Purity of tungsten sheet is measuring according to GB / T 4324.1-4324.30 requirements.

Hardness measurements according to GB / T 230 rules: If the Vickers hardness measurement method is adopted, the load should be 4.904N, according to GB / T 4340 requirements. The conversion of measured values can refer to the relevant tables; the measurement results should be consistent with the provisions of the HRA.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

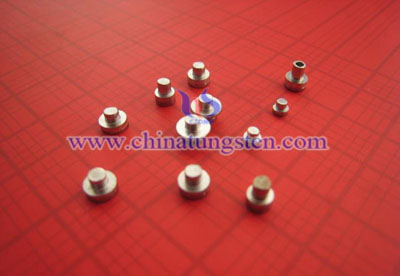

Appearance and Size Requirements of Tungsten Contacts in Cut-out

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 17:59

Appearance and size requirements of tungsten contacts in cut-out:

The appearance of tungsten contacts should look smooth, there are without the existence of burr, rust, discoloration, cold solder joint and other defects; Moreover, its electrodeposition must not have leak plating layer, peeling, de-plating and other issues.

Welds should be uniform. The thickness of the weld is thinner than a quarter of the thickness of tungsten sheet.

Contact surface of tungsten contacts do not exist depressions or remaining machining marks, its roughness Ra is less than 0.4μm.

The size requirements of tungsten contacts should be according to customer-supplied drawings, and specifications, or the dimension agreed by customer and supplier.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Technical Requirements of Tungsten Contacts in Cut-out

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 17:32

Technical requirements of tungsten contacts in cut-out:

Brazing material purity: ≥99.9%;

Weld seam strength of tungsten contacts : ≥78.45MPa;

Tungsten contacts are composed of the sit nails, tungsten sheet, and the solder, which are welding and manufacturing in the condition of hydrogen and nitrogen gas;

Tungsten sheet material must be according to JB / T9860.2 standards and its inspection of products is up to the aforementioned standard, its main technical parameters are as follows:

Purity: ≥99.95%;

Hardness: ≥70HRA;

Crystal grain number: 7500-25000 points / mm²;

Sit nail material is low carbon steel, whose carbon content is about 0.15% -0.20%, can also adopt other materials which own similar performance and composition and can be easily used for caulking.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Reference Standard of Tungsten Contacts in Cut-out

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 17:17

The following standards contain provisions in this standard by reference in the provisions of this standard.

Reference standard of tungsten contacts in cut-out:

Chemical analysis of tungsten ------ GB / T 4324.1-4324.30 --- 1984

Metallic Vickers hardness test method------ GB / T 4340 --- 1984

Metallic Rockwell hardness test method------ GB / T 230 --- 1991

Cut-out in Magneto test method------ JB / T 9864.2 --- 1999

Tungsten rod in cut-out contacts technical conditions ------ JB / T 9860.2 --- 1999

Sintered bar, rod crystal grain size of tungsten, molybdenum and alloys test method ------ GB / T 4197 --- 1984

Batch inspection Sampling procedures and sample forms (for continuous batch of checks) ------ GB / T 2828 --- 1987

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Thermal Decomposition

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 16:45

The thermal decomposition of ammonium paratungstate tetrahydrate (APT·4H2O), (NH4)10[H2W12O42]·4H2O, in air to tungsten trioxide, WO3, was investigated under non-isothermal conditions using thermal analysis coupled on-line by a skimmer system to a quadrupole mass spectrometer (TA-MS) for evolved gas analysis (EGA), with X-ray powder diffraction (XRD), with Fourier transform infrared (FT-IR) and raman spectroscopy.

The decomposition is characterized by three endothermic and one exothermic step. The first endothermic step comprises the release of crystal water resulting in the formation of crystal-water-free ammonium paratungstate. During the second endothermic step ammonia is released leaving behind ammonium hydrogen paratungstate, (NH4)6H4[H2W12O42. The presence of protons in the “roasted” APT was supported by ex situ and in situ FT-IR spectroscopy (vibration bands at 1100 and 2160 cm−1). Ammonium hydrogen paratungstate is the precursor for the metatungstate anion, [H2W12O40]6−, which is formed during the digestion of “roasted” APT with hot water.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Producing Method

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 16:44

Ammonium metatungstate producing method includes neutralization method, tungstic acid method, thermal decomposition method, solvent extraction method and ion exchange method.

Neutralization method uses secondary ammonium metatungstate and nitrate as the raw material to produce metatungstate.

Tungstic acid method using ammonia tungstate tungstic acid dissolved, add a boil deionized water in the stirring, heating by ammonia, Ph=8, in the boiling solution by adding acetic acid.

Thermal decomposition method combines ammonium paratungstate and a small amount of citric acid catalyst after mixing into the far infrared, rotary furnace, controlled thermal decomposition temperature 200 ~ 280 ℃, decomposition of about 1 h.

Solvent extraction using ammonium tungstate solution and organic extractant phosphoric acid: two (2- ethylhexyl) ester (D2EHPA) or phosphoric acid butyl ester three (TBP) and kerosene solvent to form organic phase, extract ammonium ion from ammonium tungstate solution.

Ion exchange method uses ammonium paratungstate as raw material, heating ammonium paratungstate from 1 to 8 h at 130 ~ 140 ℃, the resultant tune into a paste, to 80 ~ 100 ℃ boiling for 2 ~ 6 h, generates ammonium metatungstate solution. And then obtain the product through concentrating crystallization, filtration and drying.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Producing Method

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 16:43

Ammonium paratungstate producing method includes evaporation crystal method, neutralization crystal method and lyophilization crystal method.

Evaporation crystal method is the most widely applied in industry. Reduction evaporation is common used in the producing process. Vacuum pressure is maintained around 40kpa, evaporation temperature is between 353-363k, producing the strip of crystallization and the component of which is 5(NH4)2O•12WO3•5H2O3.

Neutralization crystal method neutralizes hydrochloric acid with concentration of 10%-20% and ammonium tungstate solution to ph value 7. If neutralizing acid under temperature 363-368k, after an hour ammonium paratungstate is produced by crystallization. If adding acid under room temperature, the solution needs to be stewing for 8-12 hours, sometimes even 24 hours, the finished ammonium paratungstate is of shape like needle and the component of which is 5(NH4)2O•12WO3•11H2O.

Lyophilization crystal method freezes ammonium tungstate solution first and heat it under vacuum low pressure environment which can obtain polyporous and drying ammonium paratungstate.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com