Tungsten Carbide Button Shape Optimization

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 16:49

- Written by Cristina

- Hits: 365

Tungsten carbide button bits applied in rock drills have different shapes: hemispherical button, conical button, parabolic button and wedge button.

As the long hole drilling being widely applied than before, the requirement for tungsten carbide button quality applied in related equipments also enhances. Hemispherical button and conical button are the most widely applied in industry. During the application process, it can be observed that regular tungsten carbide hemispherical button can be easily passivating. Tungsten carbide conical button due to its wiry bit, can be cracking under big crash and super hard rock. Thus button profile can affect its properties in a certain degree.

Researchers invented a kind of tungsten carbide button which can resist blunt. This kind of button combines the shape of hemispherical button and conical button. It turns out that this kind of tungsten carbide button is of higher hardness and wear resistance, also drill velocity is faster.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide End Mill Coatings

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 14:35

- Written by lucy

- Hits: 403

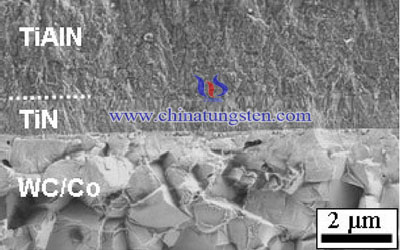

It is known that a right tool coating has a large influence for the tungsten carbide end mill in terms of cutting speed, tool life and surface finish situation.

Polycrystalline diamond is an exceptionally hard coating used on cutters which must withstand high abrasive wear. A PCD coated tool may last up to 100 times longer than an uncoated tool. However the coating cannot be used at temperatures above 600 degrees C, or on ferrous metals. Tools for machining aluminium are sometimes given a coating of TiAlN. Aluminum is a relatively sticky metal, and can weld itself to the teeth of tools, causing them to appear blunt. However it tends not to stick to TiAlN, allowing the tool to be used for much longer in aluminum.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool’s Workholding Devices

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 14:35

- Written by lucy

- Hits: 327

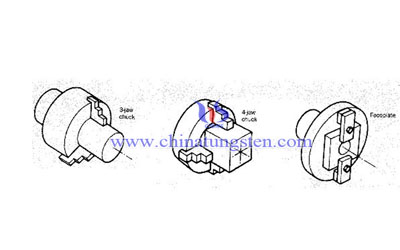

There are several most commonly used workholding devices for tungsten carbide cutting tool in nowadays’ lathe boring processes. It comprises into three-jaw chuck, four-jaw chuck and collet, as well as faceplate.

Since the three-jaw chuck is automatically centered, it is an ideal choice for holding round or hex workpieces. On latest model, if the condition is great, the runout faces limitation can be quite low , while traditionally it is usually not less than 0.025-0.075 mm. For the four-jaw chuck, it is recommended to apply in irregular shapes holding or round or hex holding to extremely low runout in time spent indicating and clamping each piece, in both cases as its independent action on each jaw. The face plate is also used for irregular shapes. Although collets’ price are higher, it perfectly combine self-centering chucking with low runout.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Tube Properties

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 18:53

- Written by Yahong

- Hits: 372

Tungsten tube is one of the tungsten products made by deep processing, which has excellent properties.

Tungsten tube owns the following properties:

High melting point;

High boiling point;

High temperature resistance;

Excellent corrosion resistance;

Productive technology: powder metallurgy;

High purity: its purity is over 99.95%;

Appearance: it appears silver grey metal luster;

Supply state: it supplied by state of sintering or processing;

With lower thermal expansion character at high temperature;

High density: if it is made by sintering, its density can reach 18.2g/cm3; if it processed by complete forging, its density can get 19.2g/cm3.While if the size is much bigger than its range, the density is only 18.8g/cm3 around.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparation of Tungsten Tube by Chemical Vapor Deposition

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 18:47

- Written by Yahong

- Hits: 408

Using WF6(high purity) and H2(high purity) as raw materials, by CVD (chemical vapor deposition) for tungsten tube preparation, its deposition temperature is controlled at 500-700 ℃.

Tungsten tube manufacturing process is as follows:

WF6 and H2 have a chemical reaction, and WF6 reduce to tungsten atoms, then a deposited tungsten layer is obtained on the deposition substrate profile.

After the end of aforementioned process, by melting the matrix in vacuum furnace or chemical etching to get deposited tungsten tube, its shape depends on the shape of deposited matrix, furthermore its size and precision is controllable.

Then, using a density meter to measure the density of the product;

Measuring micro-hardness by micro-hardness tester;

Measuring the tensile strength of the product with universal testing machine;

Observating the metallographic phase with a metalloscope and collecting metallographic phase picture with a digital camera;

Analyzing the deposition content and fluoride residue by using X-ray fluorescence spectroscopy and EDS (Energy Dispersive Spectroscopy);

Residual stress is measured with a diffractometer on tangential and axial product surface.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Overview of Tungsten Tube Performances by Chemical Vapor Deposition

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 18:39

- Written by Yahong

- Hits: 424

The tungsten tube can be processed by CVD (chemical vapor deposition), in which WF6 and H2 are as raw material gases.

CVD is an important method for the preparation of pure tungsten products. At the end of 1970, there were related reports that foreign countries had adopted this technique for preparing high purity and high density tungsten products. In recent years, China has gradually carried out research in CVD technology on tungsten microstructure, properties, structure, coating process and other fields.

The tungsten tube processing by different deposition temperature (700 ℃, 600 ℃, 500 ℃) is with different density, purity, residual stresses, micro-hardness and intensity.

Tungsten tube performances by chemical vapor deposition:

High purity :> 99.7%;

High density :> 19g / cm3;

Tensile strength range: 300-500Pa and it has considerable tensile strength with the conventional method of preparing tungsten rods in annealed state;

There is a larger residual stress along the radial and circumferential directions of tungsten tube;

Tungsten tube prepared by chemical vapor deposition with high purity and high density characteristics;

With the change of tungsten tube radius (4-21mm) and deposition temperature, the range of micro-hardness values is between 500HB and 800HV.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Riveting Tungsten Tube

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 18:34

- Written by Yahong

- Hits: 370

Riveting tungsten tube what is made of tungsten plate by riveting method is with high purity.

Riveting tungsten tube refers to convolute the tungsten plate into tungsten tubular piece, and then the rivet crack at the end of the tungsten titles is linked, so the two parts are connected.

Why tungsten tube is adopting riveting method mainly lies that its thickness is thin, the tungsten tube after sintering and polishing can not meet the thickness demand, thereby riveting method is employed. Thickness of the riveting tungsten tube is between 0.2 ~ 0.5mm, and its height can up to 850mm. Riveting tungsten tube used for sapphire crystal growth furnace will make tungsten tube with multiple different outer diameter simultaneously to fix a change of cut shape. Its main function is for insulation and thermal insulation. Riveting tungsten tube is representing polished surface and smooth metal silver.

Purity of riveting tungsten tube:

Its purity is not less than 99.95%.

Riveting tungsten tube surface:

Its surface is presenting silver gray metallic luster.

Riveting tungsten tube application:

It is mainly applied in the sapphire crystal furnace, thermocouple protection tube in high temperature furnace, high temperature sintering furnace’s support parts and other aspects.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Riveting Tungsten Tube---Riveting

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 18:21

- Written by Yahong

- Hits: 327

Riveting tungsten tube is made of tungsten plate by convoluting it.

Rivet is a mechanical vocabulary, refers to piercing holes on the two work piece(plate) with small thickness to connect them, then putting the rivet into them, and riveting with a rivet gun, for example, the hole on the shoes(sneakers, etc.), what is riveting by hollow rivet.

Riveting process: Drilling --- (Burring) --- Inserting rivet --- The top mold withstand the rivet - --Riveting forming (Or manual pier tight --- upsetting - riveting into-- - hood-shaped)

Riveting Category:

Fixing riveting. Engaging element can not act with one another, which is rigidly connected.

Sealing riveting. Riveting crack is tight, and there is no leakage of gas or liquid phenomenon, which is also a rigid connection. Riveting tungsten tube is one of the categories.

Active riveting. Binding part can be rotated to each other, is not rigidly connected. Such as: scissors, pliers and so on.

Riveting can also be divided into sub-cold riveting and hot riveting.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Nano Structured Crystalline Tungsten Oxides

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 17:39

- Written by xiaoshan

- Hits: 385

Tungsten oxides, as one of the important oxide semiconductors, are the most widely investigated materials for EC devicesbecause they can be used as intercalation host for H+, Li+, Na+,and Zn2+ to form tungsten bronze with blue color due to their special tunnel structure.

With the development of tungsten oxide films, nowday it has been widely used in many area such as energy-saving smart windows,high contrast displays, sunroofs, and antiglare mirrors.but after many studies found amorphous tungsten oxide films have poor electrochemical stability, so research work has been mainly focused on nano structured crystalline tungsten oxides. For instance, some researcher reported that WO3 nano particles showed greater charge density for proton intercalation and comparable coloration efficiency compared with conventional amorphous WO3 films. Researcher fabricated WO3 nanowires and investigated their electrochromic property. They found that the nanowires showed fast optical response time and high coloration efficiency. Researcher also reported that WO3 nanorods exhibited high electrochromic stability and comparable color display, contrast and coloration/bleaching response.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Poly Shielding for Dry Fuel Storage Campaigns

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 17:37

- Written by wenjing

- Hits: 431

Tungsten poly shielding effective for gamma and neutron fields is now available for dry fuel storage campaigns. This high temperature shielding easily withstands the heat generated during forced helium drying which allows tungsten poly shielding to remain in place during the dewatered phase. Tungsten poly shielding material moderates and attenuates both fast and intermediate neutrons while the outer tungsten poly layer eliminates primary and secondary gamma rays. The lightweight design allows access to the weld locations without disturbing the majority of the shield package. 80-95% reductions in exposure rates have been achieved in field applications.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com