Comparison of Barium Tungsten Electrode and Thorium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 May 2025 14:52

Barium tungsten electrode and thoriated tungsten electrode are two common tungsten-based electrode materials, which are widely used in welding, electric light sources, electronic devices and other fields. The following is a comparative analysis from five dimensions: component characteristics, performance, application field, environmental safety and market trend:

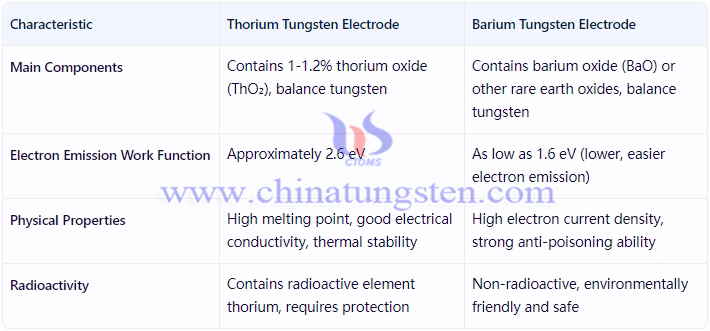

I. Composition and Basic Characteristics

II. Performance Comparison

1. Electron Emission and Arc Initiation

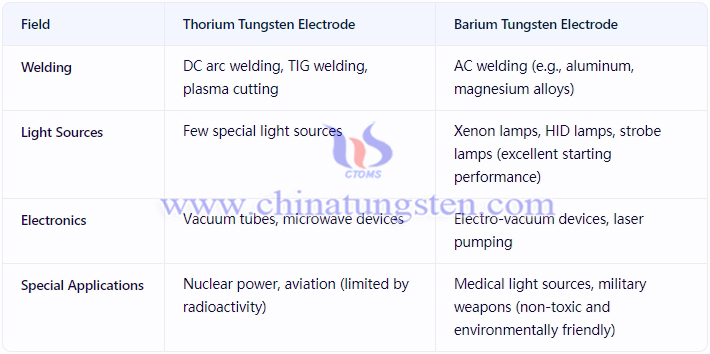

Thorium Tungsten Electrode: Due to the radioactive activation of thorium, it has stable arc initiation and good arc stiffness, suitable for DC welding (e.g., stainless steel, titanium alloys).

Barium Tungsten Electrode: Its low work function enables excellent starting performance, suitable for high-frequency discharge devices (e.g., xenon lamps, HID lamps), but DC arc stability is slightly inferior to thorium tungsten.

2. Arc Stability and Pollution Resistance

Thorium Tungsten Electrode: Stable under overload voltages, with easy tip shape maintenance, but long-term use may cause pollution due to thorium volatilization.

Barium Tungsten Electrode: Strong anti-poisoning ability, suitable for complex environments (e.g., sulfide-containing atmospheres), but barium may volatilize at high temperatures.

3. Service Life

Thorium Tungsten Electrode: Longer lifespan due to thorium's high melting point, but radioactive nature increases maintenance costs.

Barium Tungsten Electrode: Non-radioactive and easy to maintain, but lifespan may be shorter under high-frequency use compared to thorium tungsten.

III. Applications

IV. Environmental Safety

1. Thorium Tungsten Electrode:

Radioactive Hazard: Thorium releases α/β rays through dust or gas, which may be carcinogenic with long-term exposure.

Protection Requirements: Requires radiation-proof clothing, distance maintenance, and reduced exposure time.

Regulatory Restrictions: Phased out in Europe and the USA, with strengthened controls in China.

2. Barium Tungsten Electrode:

Non-toxic and Environmentally Friendly: Complies with RoHS standards, no special protection required.

Waste Disposal: No radioactive pollution, low recycling costs.

V. Market and Economy

1. Cost

Thorium Tungsten Electrode: Lower raw material costs, but radioactive disposal increases overall costs.

Barium Tungsten Electrode: Complex preparation process (e.g., impregnation method), higher unit price, but lower long-term use costs.

2. Market Trends

Thorium Tungsten Electrode: Declining demand, only used in specific fields (e.g., nuclear power maintenance).

Barium Tungsten Electrode: Rapidly growing market demand, especially in high-end manufacturing (e.g., semiconductor equipment) and regions with strict environmental regulations.

VI. Selection Recommendations

Prioritize Thorium Tungsten Electrode: If you need extreme DC arc stability and can accept the cost of radioactive management (such as nuclear power, aviation).

Prioritize Barium Tungsten Electrode: If environmental protection, high-frequency performance, or long-term use costs are prioritized (e.g., light sources, medical devices).

CTIA GROUP specializes in flexible customization of tungsten and molybdenum products worldwide. We can customize tungsten and molybdenum products of various specifications, performances, sizes and grades according to customer needs. If you need any consultation, please send an email to sales@chinatungsten.com.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com