The Hardness of Tungsten Tube Prepared by CVD (Chemical Vapor Deposition) (1)

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 18:08

- Written by Yahong

- Hits: 422

Tungsten tube prepared by CVD (Chemical Vapor Deposition), which has the same diameter and other factors, and the deposition temperature is between 500 ℃ and 700℃, the hardness test results of deposited tungsten layer shows that the hardness of tungsten tube prepared at different temperature are higher than 500HW. If the diameter is different, the hardness of tungsten tube will decrease with the increasing of tungsten tube diameter; at different deposition temperature, the hardness of tungsten tube prepared will decrease resulting from the increase of distance between deposition matrix and tungsten tube.

The analysis of the change of the deposition layer hardness result shows that the change is related to the internal stress generated in the cooling process after the end of deposition and the crystal growth of the film layer. In the process of the growth of the film deposition in the inner surface of the base, the matrix is perpendicular to the columnar grain growth caused by the mutual pressing of the deposited layer, which having a larger residual stress. The smaller the radius of the tungsten tube, the residual stress caused by column crystal squeezing each other will be larger. In the range of 273-1273K, average linear expansion coefficient of tungsten, copper are 4.4×10-6K-1,17.0×10-6K-1. In the cooling process after depositing, tungsten tube volume shrinkage is much smaller than the copper matrix, which will result in greater residual stress on the surface of deposition tungsten tube.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Density of Tungsten Tube by CVD (Chemical Vapor Deposition) Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 18:06

- Written by Yahong

- Hits: 465

Adopting CVD (Chemical Vapor Deposition) method, using WF6 and H2as raw materials, and the deposition temperature range is about 500-700 ℃ to prepare tungsten tube.

WF6 is reduced to tungsten atom after the chemical reaction with H2, tungsten deposition layer will deposit on the deposition matrix. Then, the method of obtaining the deposition of tungsten tube is: either by chemical etching in the matrix or putting it in a vacuum furnace to melt.

The result which is using the buoyancy method to measure deposit density of tungsten tube at different temperature shows that under different deposition temperature, tungsten tube has a high density : >19g/cm3. As the deposition temperature increasing, the restore process accelerated, and the reduction of tungsten atoms on the deposited growth interface will be further growing, which will lead to obvious refinement of microstructure grain and growth direction of the deposited layer will tend to be messy, resulting the little decrease of deposition layer density.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Purity of Tungsten Tube by CVD (Chemical Vapor Deposition) Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 18:02

- Written by Yahong

- Hits: 414

CVD (Chemical Vapor Deposition) is a vapor phase growth method for preparation of the material, which is a technology to get deposited solid thin film on the surface of matrix by means of space gas phase chemical reaction, that is to say, placing one or several elements of single substance gas and compound gas which are the content of thin film in the reaction chambers with matrix, and then they will react.

Deposition temperature is 500-700 ℃ around, and WF6 with high purity and H2 with high purity as raw materials to prepare the tungsten tube by CVD (Chemical Vapor Deposition).

WF6 and H2 make an interaction and WF6 will reduce to tungsten atom, then, tungsten deposition layer deposited on the deposition matrix. After that, depositing tungsten tube can be gotten by chemical etching or melting in a vacuum furnace, its dimensional accuracy may be controlled.

Tungsten tube X-ray fluorescence scanning analysis showed that the purity of tungsten tube is high by CVD method, which is embodied as: in deposition film, the tungsten content is not less than 99.7%.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Drill

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 17:46

- Written by chunmeng

- Hits: 391

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, other tools and instruments, and jewelry.

Tungsten carbide drill is very abrasion resistant and can also withstand higher temperatures than standard high speed steel tools. Tungsten carbide drill is often used for machining through materials such as carbon steel or stainless steel, as well as in situations where other tools would wear away, such as high-quantity production runs. Because tungsten carbide tools maintain a sharp cutting edge better than other tools, they generally produce a better finish on parts, and their temperature resistance allows faster machining.

Tungsten carbide drill’s features:

1. It can fit the various drilling of complicated material and the cutting speed is depending on you.

2. With good wear resistance and the dedicated high-performance alloy blades, the tungsten carbide drill can reduce the damage to the tools.

3. With multilayer cutting side edges, it can keep the small cutting resistance.

4. Besides the right-angle handle, it has various handle types, which are suitable for different kinds of drilling machines.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Construct of Tungsten Collimators

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 17:29

- Written by wenjing

- Hits: 439

Tungsten collimators are essential component of Industrial Radiography set up as they provide radiation safety to the operating personnel and general public at large by directing the emerging radiation beam to the useful area of exposure. Tungsten collimator with optimum design features also helps in reducing the scattered radiation which is turn results in radiographs with better sensitivity. Tungsten collimators are fabricated using tungsten alloy material as cladding. Tungsten alloy shielding for the directional collimator is designed to provide a 50 degree radiation beam and is encased with stainless steel and totally sealed by argon arc welding. The panoramic collimator is constructed with two shields designed to provide a 30 degree panoramic radiation beam. The shields are encased with stainless steel and totally sealed by argon arc welding.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Density of Poly Tungsten Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 17:27

- Written by wenjing

- Hits: 393

Poly tungsten radiation shielding is a definition for tungsten-polymer composites which are new substitutes for lead or sintered tungsten base heavy alloys. Poly tungsten radiation shielding composite systems are a combination of two components: polymer which is acting as filler and combines high weight percent of tungsten powder. It is possible to introduce, for example, 97wt% of tungsten powder to nylon filler. The final product will reach to density of 13 g/cc .Commercial lead density is between 10.0-10.8 g/cc. Tungsten base heavy metal alloy will vary between 16 to 18.5 g/cc. High density tungsten-nylon may vary between 10 to 14 g/cc. Tungsten- polymer will not require sintering as heavy metals, since it is being injection molded as a regular polymer.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button TPA Pressing

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 17:04

- Written by Cristina

- Hits: 383

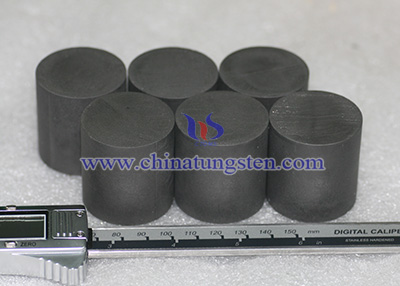

Tungsten carbide button is widely used in mining and coal mining industry tools. Owing to the severe environment, the quality for the product should be extremely high. Tungsten carbide button produced by conventional hydraulic pressing has uneven density, low quality and low producing efficiency. Tungsten carbide button is produced by powder metallurgy and TPA is a kind of pressing method. TPA pressing which is high degree of automation, pressing efficiency is ten times higher than hydraulic pressing. As a result it is suitable for mass production of tungsten carbide button.

Since TPA pressing was applied in producing tungsten carbide button, it reduces the rate of spoiled. This method is simple to operate and the producing efficiency improves a lot. The finished product is of high quality and high density, service life also extends a lot. So TPA pressing has been a vital method in producing tungsten carbide button.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Density Affects by TPA Pressing Method

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 17:02

- Written by Cristina

- Hits: 418

Metal powder pressing method includes single pressing process, double pressing process, floating pressing process, friction pressing process, etc. Tungsten carbide button produced by different pressing process has various density distribution law. Density is an important factor that would affect product quality. Besides from gradient and properties of metal powder, pressing mould surface roughness, tungsten carbide button density is also affected by powder movement after being pressed in the pressing mould. The friction between powder and side of pressing mould will affect density of tungsten carbide button.

The conventional hydraulic pressing adopts single pressing process. Shape and thickness of powder layers are quite different. So the density is uneven. TPA pressing method adopts double pressing process. There is a neutral layer during the process, the powder in this layer almost stay still during the pressing process. Neutral layer is pressed from both up side and down, compared to single pressing process, the density is even.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button TPA Mould Design

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 16:54

- Written by Cristina

- Hits: 374

Tungsten carbide button density is an important factor which affects tungsten carbide button quality. Apart from choosing proper pressing method, the size of material forming zone is very important.

If the forming zone is too low, the upper punch can not reach to the metal powder, and the lower punch can not reach the top layer which will cause the high pressure of the lower layer thus the density is uneven. And also the size of finished product will be too small.

If the forming zone is too high, both the upper punch and lower punch will not have enough power to press the middle layer. As a result the density in the neutral layer is lower than the other part. The punch needs to go deep inside the mould which will cause air block in the mould; the metal powder will stick to the punch and will cause damage. Also the mould will be overloaded; size of tungsten carbide button will be too large.

Only when the forming zone height is proper, the pressure on neutral layer from upper and lower punch is even, tungsten carbide button will be high density and quality.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Nano Crystallization

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 16:53

- Written by Cristina

- Hits: 344

Tungsten carbide button is used in the coal cutter drilling tools, mine machinery tools and road maintenance tools. It is also widely applied for rock tools, mining tools for use in quarrying, mining, tunneling, and civil constructions.

Requirement of tungsten carbide button in rock drill is super high. The hardness should be high enough to increase its wear resistance; also the tenacity should be able to resist cracking. Nano crystallization can enhance its hardness and wear resistance. Research shows that under the same amount of binder, if the tungsten carbide grain size is less than 1um, tungsten carbide button hardness and tenacity improve a lot.

As the tungsten carbide grain size getting smaller, the properties of tungsten carbide button arise. Some researchers applied nano materials to tungsten carbide button sintering process, and it shows the sintering temperature falls down. Tungsten carbide button hardness, wear resistance, tenacity also improve a lot. Thus its service life extended and cut the producing cost.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com