Tungsten Trioxide Electric Transport Ⅰ

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 December 2015 16:22

In the diamond resistivity, we explore resistivity, grain resistance, grain boundary resistance and other physical relaxation frequency variation by measuring the DC resistivity method and AC impedance spectra at high pressure and in the pressure range 36GPa. Taking WO3 ceramics in electrical transport properties of under high pressure as experiment, we found that discontinuous change in the resistivity of the sample which appears in pressure at 1.8, 21.2 and 30.4GPa, which reflects the pressure-induced structural phase transition WO3. After relieving the resistivity and it did not recover to its original value, which indicating that the structure of WO3 phase transition is irreversible.

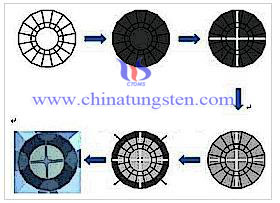

Four-electrode preparation process schematic diagram

In addition, the grain resistance and abnormal changes in the activation energy of conduction 3 and 10GPa is different from previous research by Raman and other structural phase transition related. The law is that under high pressure resistivity with temperature variation shows WO3 from atmospheric pressure to nature 25.3GPa consistent with semiconductors. The new peaks by synchrotron radiation X-ray diffraction experiments at about 24 and 31GPa emergence confirms the structural phase transition, indicating the correctness of the results of electrical measurements and related analyzes.

We found that the resistivity of the sample appeared discontinuous changes in the 4.3 and 10.5GPa by measurement of nanometer WO3 high-pressure in-situ resistivity, which reflects the electronic structure of nanometer WO3 phase transformation, the scale effect of grain led to a phase change of the hysteresis ; changes in the slope of the resistivity at 24.8 and 31.6GPa reflect the structural phase transition of nanometer WO3; resistivity from 36GPa relief to atmospheric pressure and did not return to the initial state value, all that indicates a structural phase transition of nanometer WO3 is irreversible phase variable. Variable temperature resistivity studies shows that nanometer WO3 from atmospheric to 36GPa keeping the transmission characteristics of the semiconductor, which is similar to the material WO3. The discovery of frequency AC impedance spectra appears under pressure grain boundary effects; grain resistance at 4.6 and discontinuities 10.3GPa department also provides the basis for the electronic phase transition; pressure-induced relaxation frequency changes show 10.3GPa relaxation time in the electronic phase transition at the shorter. Traces of grain boundary relaxation frequency also shows grain boundary effects are not completely disappeared, which is consistent conclusions with Nyquist impedance spectra.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Electric Transport Ⅱ

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 December 2015 16:17

In the research for electrical transport of BaWO4 in that under high pressure, we use the insulation spacer technology to prevent the introduction of additional impedance of error in the experiment, which in order to obtain more accurate data. We obtain the pressure-induced relaxation phenomena and activation energy by studying the crystal grain boundary effects and measuring high voltage of BaWO4 impedance with spectroscopy with DAC surface use in integrated microcircuit.

When semi-circular impedance gets together and the resistance is large, the effect of lead inductance is small to BaWO4 polycrystalline powder sample. However, not all the experiments can measure a clear semi-circular, and some will be in the high frequency region, which can show incomplete semi-circular and in the low frequency region is compressed to show semi-circular. With the improvements of measure technology, we can clearly see a semicircular arc in the high frequency region and low frequency.

Grain resistance and grain boundary resistance can be fitted by a semicircle, which intercepts the resistance in size. With the pressure of the grain boundary resistance is different from the pressure-induced changes in grain resistance changes. In fact, most of changing is made from high pressure. Grain resistance and grain boundary resistance with discontinuous change in pressure indicates changes in the electrical transport properties, reflecting the pressure-induced structural phase transition.

In the phase transition, the type Freckle and Scotty defects increase, this is due to atomic thermal process enthalpy fluctuations caused by excitation induced phase transformation. From 6.9 to 8.9GPa, grains have a relaxation frequency increasing trend; this trend with the previous direction of movement of the relaxation peak is consistent. This is due to the different phases within the structure of the grain extraordinary relaxation frequency. Because in this pressure range, there is scheelite, fergusonite and BaWO4-II phase appear, phase has a shorter relaxation time.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Electric Transport Ⅲ

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 December 2015 16:14

In the phase of transition, the pressure reduces the height of the barrier, and it is easier for the electric charge to pass through fergusonite and BaWO4-II,which reduces the relaxation time. Average relaxation time leads to an increase of total relaxation frequency, which also represents an increase of relaxation frequency response characteristic. The pressure ranges from 2.6 to 6.9GPa activate and the grain boundary can be -9.09meV / Pa, which shows active energy with increasing pressure and a decreasing trend for grain boundaries BaWO4 powder sample.

In the phase of transition, the pressure reduces the height of the barrier, and it is easier for the electric charge to pass through fergusonite and BaWO4-II,which reduces the relaxation time. Average relaxation time leads to an increase of total relaxation frequency, which also represents an increase of relaxation frequency response characteristic. The pressure ranges from 2.6 to 6.9GPa activate and the grain boundary can be -9.09meV / Pa, which shows active energy with increasing pressure and a decreasing trend for grain boundaries BaWO4 powder sample.

From 6.9 to 8.9GPa, grain boundary activation energy also shows a downward trend, which reduces the rate pressure range is much larger than 2.6-6.9GPa. Activation energy of grain boundaries is described as change of the pressure in the pressure range 2.6-8.9GPa interval. The pressure of activation can play the role of a negative contribution. When the pressure exceeds 8.9GPa, the boundary activation energy conversely grains as the pressure increases. This shows that in the 8.9-13.7GPa pressure range, the pressure on activation energy changes were positive contribution to the role, and the charge carriers conducting are more difficult. More than 13.7GPa, the active energy pass through easily with the pressure decreases.

We can find that impedance spectra arc described grain structure in 7GPa phase transition, which occurs in grains, then the transition to the grain boundaries. Changes in the grain and grain boundary relaxation frequency are caused by a structural phase transition. Within 6.9-8.9GPa pressure range, grain boundary activation energy can play a role in the negative contribution; the charge carries more easily through the grain boundaries. In addition, within 6.9-8.9GPa, rising grain and grain boundary relaxation frequency also shows that the relaxation process takes less time during the phase transition. Therefore, we can obtain the DC resistivity and AC impedance spectroscopy methods combine with synchrotron radiation X-ray diffraction methods .we can analyze the material from hyperbaric and gain nakedness WO3, variation and electrical properties and structure of BaWO4.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Strengthen Ammonium Paratungstate Crystallization-- Ultrasonic Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 December 2015 08:21

| APT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sodium Tungstate and Potassium Iodide System for Hydrogen Peroxide Catalysis

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 December 2015 20:41

| Sodium Tungstate Supplier: Chinatungsten Online http://sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

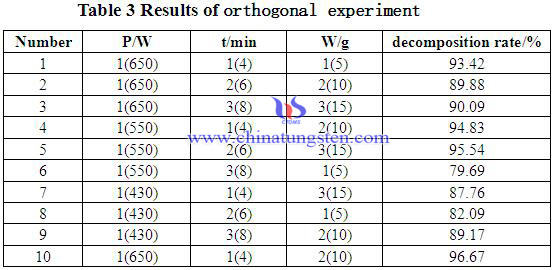

Microwave Calcination Preparation WO3 from Ammonium Paratungstate 2/2

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 December 2015 18:36

For microwave calcination preparation WO3 from ammonium paratungstate 1/2,please see in

http://news.chinatungsten.com/en/tungsten-information/81906-ti-10605

| APT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

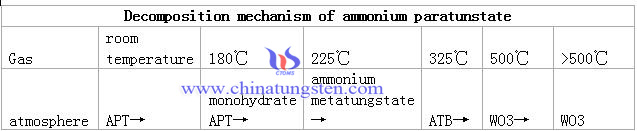

Microwave Calcination Preparing WO3 from Ammonium Paratungstate 1/2

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 December 2015 18:28

Ammonium paratungstate is a kind of white crystal of scatter, fluidity, began to lose ammonia in the air when heated to 60℃, dehydration with the temperature reaches 100℃, began to change to yellow WO3 with continue the temperature raising up to 450℃. Thermal decomposition chemical equation is as follows:

| APT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Ceramic Doping Object

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 December 2015 18:06

Tungsten trioxide is a common metal ceramics, metal ceramics with low density, high hardness, wear resistance, thermal conductivity, both the advantages of ceramics and metals, metal ceramics both ductile metals, high heat resistance and good thermal conductivity stability, but also has ceramic high temperature, corrosion and wear-resistant features. Tungsten oxide ceramics not only has the general characteristics of the cermet also has a pressure-sensitive characteristics, the researchers in order to improve the pressure-sensitive properties of tungsten trioxide ceramic, generally choose the way doping suitable dopant added to the fine ceramic varistor characteristics The form has played a key role.

Varistor under normal circumstances would be to add a doping element to the following three main purpose:

(1) ceramic sintered tungsten trioxide poor performance, doped tungsten trioxide way alter the ceramic sintering process, to help sintering purpose without doping ceramics sintered tungsten trioxide can densification. For example, low melting point metal oxide in a liquid phase process capable of forming tungsten trioxide to tungsten in the ceramic sintered tungsten trioxide promote densification of the ceramic.

(2) The reason why the presence of tungsten oxide ceramic varistor characteristic, because the internal and external surfaces of the grains have different defects, such that different internal and external resistivity, indirect control defect types of elements, doping and other species by controlling the doping and distribution of defects on the pressure-sensitive properties of its essential.

(3) capable of controlling the situation doping element grain growth, adjust the size of the varistor voltage. Bi, Co, Sb and Pr and other transition metals are able to significantly improve the performance of the ceramic junction burn doping elements and the pressure-sensitive properties.

Doped Bi2O3 and Pr6O11 can effectively improve the sintering properties of tungsten trioxide but in order to achieve high density and pressure-sensitive properties of tungsten trioxide fine ceramics, on the basis of its needs, and look for suitable doping elements to improve trioxide Tungsten ceramic varistor properties.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Extraction Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 December 2015 18:02

Some countries attach great importance to the recovery and utilization of secondary resources of tungsten, tungsten especially in some major consuming countries such as the US, Germany and Japan. Germany Star can company's main business is international trade refractory metals, long-term acquisition of various tungsten scrap at low prices from around the globe, extraction and separation of tungsten trioxide in a variety of tungsten scrap production line.

Currently, the extraction of tungsten trioxide general process is: the formation of tungsten ore after leaching soluble tungstate, cleaning after acidification or evaporative crystallization of ammonium paratungstate (APT), calcined to generate secondary sodium tungstate tungsten trioxide; also The hydrochloric acid into tungstic acid, tungsten acid decomposition of tungsten trioxide; resin method or membrane electrolysis technology to prepare tungsten trioxide.

U.S. tungsten trioxide extraction process is: first with sodium hydroxide solution tungsten-containing waste cooking, generating sodium tungstate, sodium tungstate crystals crystallized; then sodium tungstate crystals are dissolved in the mother liquor loop, to regenerate sodium tungstate solution was evaporated to form the ammonium and sodium tungstate containing tungsten trioxide, silicon, arsenic and other metals mother liquor, the mother liquor can be recycled, avoiding the past the process releases large amounts of acid and other issues.

Calcination method: First, in the 600 ~ 650 ℃ to remove moisture, organic impurities and carbon, and tungsten disulfide high-temperature calcination makes oxidized tungsten trioxide reacts with ammonia generated sodium tungstate, remove iron, fluorine. Silicon, phosphorus and other insoluble matter.

Electrolysis: (1) mixing the molten salt and water removal (2) the electrode process (3) Pre-electrolysis (4) electrolysis (main parameters: temperature, cell voltage, current density, electrolysis time, etc.) (5) separated from the tungsten powder collect. Preparation of raw material of the present invention is a low cost, short process, simple equipment, there is no solid, liquid and gas waste emissions, no secondary pollution, at low cost direct electrolysis of tungsten powder prepared from tungstate.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Importance for Tungsten Trioxide Extraction

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 December 2015 17:59

Tungsten is one of the strategic resources of China, its importance means extracting tungsten from tungsten trioxide industrial waste - turning waste into treasure is typical shift resources into the way. With the rapid development of China's industrial economy, the demand for all kinds of mineral resources is increasing rapidly, and its growth rate is much higher than the growth rate of the national economy, mineral resources, stockpiling, production, consumption contradiction between the increasingly prominent.

On the other hand, China caused extensive production and development of a great waste of resources, but also exacerbated the damage to the environment pollution and resource. In order to improve the level of protection of China's mineral resources, making full use of his country's resources, mineral resources in China would like to take advantage of the way "to develop a resource-based, two-renewable resources, new and alternative resources development and utilization of both," the direction of change. Tungsten Resources it is a strategic resource, reserve resources, is one of China's protection of minerals.

The storage of China tungsten ore is the largest in the world, in 2009 the tungsten reserves (in tungsten trioxide mainly dollars) to 1.386 million tons. According to the US Bureau of Mines statistics, in 1994 China accounted for 44.3% of tungsten storage world, but by 2001 had fallen to 35.5%. However, the Chinese tungsten ores taste is not high, Bonanza (referring to tungsten oxide content of 1% of deposits) accounted for only one-fifth of total reserves; easy beneficiation reserves account for only 27.2% of total reserves, total reserves .

More than 70% of scheelite low taste, large complex symbiosis, smelting difficulty. China tungsten ore utilization of secondary resources (ie, tungsten-containing industrial waste) is also very low, only about 10% of tungsten supply, while in developed countries this indicator was above 30%. In addition, China's domestic recycling waste tungsten alloys, waste carbide in more than two-thirds are imported from foreign waste. According to statistics, every year a large number of tungsten trioxide containing compounds are used as garbage abandoned. Therefore. The extract scrap tungsten trioxide is the most important moment, an urgent matter.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com