Explore Tungsten Trioxide Photocatalytic Property

- Details

- Category: Tungsten Information

- Published on Thursday, 21 January 2016 14:53

- Written by qiongyao

- Hits: 248

Photocatalyst is a general term of nanoscale titanium dioxide that has a photocatalytic function on behalf of the optical semiconductor material, which is applied to the substrate surface. Under the action of ultraviolet light, it can effectively degrade the air poisonous gases; can effectively kill a variety of bacteria. Fungi and bacteria can release toxins decomposition and it is a harmless treatment; it also has a deodorizing, antifouling, air purification and other functions. Photocatalyst materials are nano TiO2, ZnO, CdS, WO3, Fe2O3, PbS, SnO2, ZnS, SrTiO3, SiO2, etc. In all of the photocatalyst material, in addition, the enzyme aldehyde not only has high photocatalytic activity, and has acid corrosion, chemical resistant, non-toxic, etc. Photocatalyst has a high price, and therefore most of the use of Nano-titanium dioxide as the main raw material on the market.

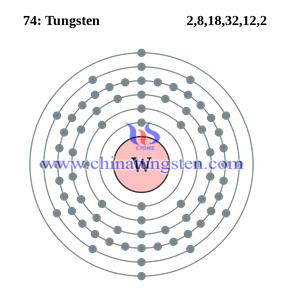

As can be seen from the figure, the atomic weight of tungsten (W) is 74, and titanium element atomic weight is 22, the structure of atomic is more complicated. Tungsten is rare heavy metals. It was found that tungsten trioxide (WO3) and titanium dioxide (TiO2) are similar. However, they are not the same nature. Energy tungsten trioxide (WO3) outer electrons is less active compared to the titanium dioxide, its electron volts insufficient 3.2, that is to say, just 400 nm wavelength of visible light is activated.

As can be seen from the figure, the atomic weight of tungsten (W) is 74, and titanium element atomic weight is 22, the structure of atomic is more complicated. Tungsten is rare heavy metals. It was found that tungsten trioxide (WO3) and titanium dioxide (TiO2) are similar. However, they are not the same nature. Energy tungsten trioxide (WO3) outer electrons is less active compared to the titanium dioxide, its electron volts insufficient 3.2, that is to say, just 400 nm wavelength of visible light is activated.

Studies have shown that, photocatalyst tungsten trioxide is indeed light catalysis in the indoor environment, which can purify the indoor environment, for example, in fluorescent lamps (also called fluorescent) light irradiation (wavelength 400 nm) occurred photocatalysis. However, the activity is not enough. The cost of tungsten trioxide nanoscale production is too high; the production process is complex, the process requires a large number of civilian photocatalyst tungsten trioxide.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Preparing Potassium Doped in Round Tungsten Aluminum Strip from Ammonium Paratungstate—Preparation Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 January 2016 20:10

- Written by chunyan

- Hits: 271

Potassium doped in round aluminum tungsten is the raw materials in electric light manufacturing, electronic devices in ANTIDROOPING tungsten filament and vacuum spray plating tungsten hinge wire and other high-temperature heating body and resistance to high temperature components. A method for preparing potassium doped in round aluminum tungsten strip is introduced in this paper.

Specific steps:

1. Choice of materials: select special size of ammonium paratungstate distribution with crystalline in FSSS for 40 to 50μm and loose density in 2.1~2.5g/cm3 as raw material;

2 Mild reduction ammonium paratungstate: the raw material mild reduction in furnace in seven ranges of temperature to produce special intermediate ammonium tungsten bronze (ATB). Among them: seven ranges of temperature are 300, 360, 400, 420, 430, 450, 420℃, rate of hydrogen flow at 0.2~0.3m3/h,;

3. AKS doping: mix wet ATB with potassium silicate, aluminum nitrate solution dissolved in deionized water, and make potassium, silicon, aluminum adopted in the pores of ATB, doped ATB formed;

4. Direct reduction: ATB directly reduction in seven temperature reduction furnace a and fine grain tungsten powder B with FSSS 2.2 ~ 2.6μm generated; coarse grain tungsten powder D with FSSS 3.3~4.2μm generated in the same way;

5. Pickling: washing fine grain tungsten powder B, coarse tungsten powder D respectively with hydrochloric acid of concentration 6~8%, hydrofluoric acid of 6~8% to remove dopant and impurities;

6. Mixing powder: mixing the fine particles of tungsten powder B, coarse grain tungsten powder D according to a certain weight ratio after pickling;

7. Cool down and static pressure;

8. Pre-sintering: 120 ~45min under temperature of 40℃;

9. Vertical melting: directly electricity to sintering under the protection of hydrogen gas.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sodium tungstate concentration on Ni-Co-W-P alloy coating influence 2/2

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 January 2016 18:37

- Written by linlu

- Hits: 256

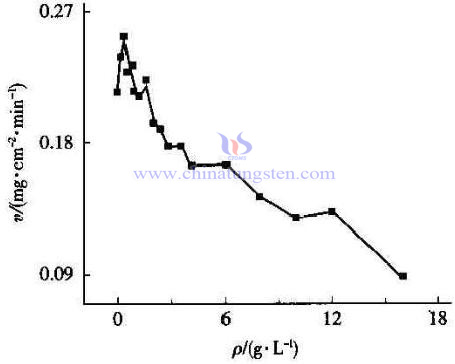

Influence of sodium tungstate on magnetic property: chemical plating solution mass concentration of sodium tungstate had significant effect on the magnetic coating, with the increase of mass concentration of sodium tungstate, thin film of coercive force decrease after rising first, peaked at 0.4 g/L. Sodium tungstate concentration on the influence of saturation magnetization intensity and its influence on coercive force trend similar to that of low concentration with the increase of mass concentration of sodium tungstate, coating of the saturation magnetization increased, and at the age of 0.8 g/L reached its highest 22 emu/g, then a downward trend. W mass fraction in the coating increased with the increase of mass concentration of sodium tungstate, so sodium tungstate mass concentration of magnetic can be attributed to the influence of W on the influence of coating microstructure and composition.

Influence of sodium tungstate on magnetic property: chemical plating solution mass concentration of sodium tungstate had significant effect on the magnetic coating, with the increase of mass concentration of sodium tungstate, thin film of coercive force decrease after rising first, peaked at 0.4 g/L. Sodium tungstate concentration on the influence of saturation magnetization intensity and its influence on coercive force trend similar to that of low concentration with the increase of mass concentration of sodium tungstate, coating of the saturation magnetization increased, and at the age of 0.8 g/L reached its highest 22 emu/g, then a downward trend. W mass fraction in the coating increased with the increase of mass concentration of sodium tungstate, so sodium tungstate mass concentration of magnetic can be attributed to the influence of W on the influence of coating microstructure and composition.| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Prepared from Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 January 2016 20:08

- Written by chunyan

- Hits: 239

Ammonium metatungstate is an important tungsten compound, mainly used in petroleum cracking, organic synthesis, nitration and other industries as a catalyst. The dosage of ammonium metatungstate is increased with the rapid development of oil refining. The traditional way crystallization to prepare ammonium metatungstate from ammonium paratungstate has high investment, energy consumption and unstable quality of the resulting product, poor solubility, can not meet the need of catalyst.

Ammonium paratungstate used as raw material to leaching out the solution, then dilute ammonium metatungstate solution turns into a concentrated solution, and spray and drying the concentrated ammonium metatungstate solution to prepare ammonium metatungstate crystal.

Specific steps are as follows:

1. Leaching out the wet ammonium paratungstate: to wet ammonium paratungstate content 5 ~ 10% water as raw material and mix with nitric acid (HN03) to prepare dilute ammonium metatungstate solution;

2. The dilute ammonium metatungstate prepared by the step 1 goes through many times of static and precipitation, filtration and heat to concentration and then obtain the concentrated ammonium metatungstate solution;

3. Spray and dry, make the material dried quickly into ammonium metatungstate powder.

Its advantages lie in:

1. There is no need to roasting, so the rotary furnace equipment is useless, therefore to reduce investment of fixed;

2. The actual recovery rate of ammonium metatungstate increased;

3. Slowly and continuously feeding overcomes the problem of low solubility of ammonium metatungstate, to get ammonium metatungstate solution with high content of tungsten trioxide;

4. Use wet ammonium paratungstate product as raw material saves the process of drying and packing, to achieve the purpose of saving energy and reducing cost.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Sodium tungstate concentration on Ni-Co-W-P alloy coating influence 1/2

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 January 2016 18:34

- Written by linlu

- Hits: 248

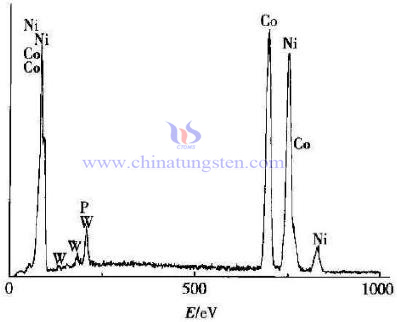

There are many preparation methods of magnetic thin film. Because the bracket is made of nickel - titanium wire or stainless steel wire, complex shape, the first choice is the chemical plating method. Chemical plating has low cost, simple operation and uniform coating, and low porosity. This paper mainly discusses the Ni Ti shape memory alloy stent - table and electroless Ni-P-Co-W magnetic thin film in the formula of sodium tungstate concentration of Co-W-Ni-P film morphology and performance.

There are many preparation methods of magnetic thin film. Because the bracket is made of nickel - titanium wire or stainless steel wire, complex shape, the first choice is the chemical plating method. Chemical plating has low cost, simple operation and uniform coating, and low porosity. This paper mainly discusses the Ni Ti shape memory alloy stent - table and electroless Ni-P-Co-W magnetic thin film in the formula of sodium tungstate concentration of Co-W-Ni-P film morphology and performance.| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com