Coarse Grain Tungsten Powder Restored from Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 21 January 2016 17:53

- Written by chunyan

- Hits: 318

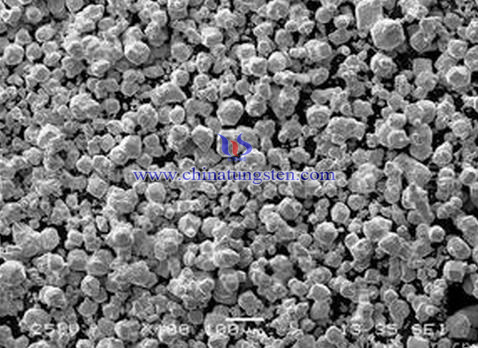

Ultrafine and ultracoarse tungsten carbide (WC) grains are the two development directions of tungsten carbide in recent years. Coarse grain WC powder is the important raw material for coarse grain tungsten carbide. It has been widely used in oil drilling and petroleum perforating element material, anti ballistic missile system and heavy armor penetrator material, because of the less structural defects at high temperature, high hardness, low micro strain and a series of special properties.

Tungsten powder of coarse particles obtained by one-step reduction method from tungsten trioxide (WO3), in molybdenum wire furnace under the high temperature of 1200℃ at present industrial. However, tungsten particles obtained by this method usually in shape of nearly equiaxed, and the size is relatively small with poor formability, which make it to have to forming by adding organic matter as a binder. And that is not conducive to large products formed and properties controlled. Coarse grain powder was prepared by direct reduction process of ammonium paratungstate (APT) in this paper, and carbonization for preparing WC powder.

The preparation steps are as follows:

1. Use the tungstate solution of 37% concentration; place it in the reaction furnace to heating, evaporation and crystallization to obtain APT crystal;

2. Grinding and crushing the APT, pass through 60 mesh sieve for controlling crystal size;

3. Place APT in a single hydrogen furnace for reduction, set the reducing conditions as follows: hydrogen section flow for 50ml/cm2.min, temperature at 850℃ to 1000℃, keep warm for 90~180min, then tungsten powder obtained;

4. Put tungsten powder into the deionized water, vibration with ultrasonic, cleaned until the solution cleared, drying, grinding, sieving;

5. Mixing tungsten powder and carbon black in a certain proportion and placed in a carbon tube furnace, carbonization under high temperature 1700~1800℃, then milling and sieving to obtain coarse grain WC powder.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Lanthanum Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 21 January 2016 17:17

- Written by yiping

- Hits: 267

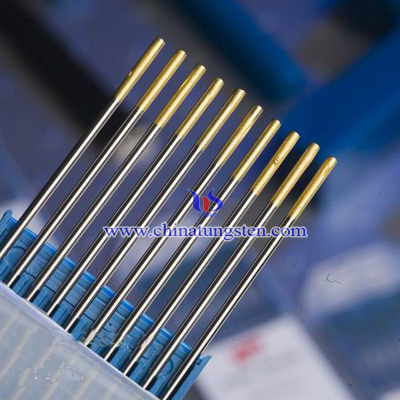

Currently, the tungsten electrode, rare earth tungsten electrode and the composite electrodes are widely used in chemical, electrical, mechanical, construction, aerospace and other fields. But with the development of scientific and technological, tungsten inert gas welding and plasma welding field, there are higher requirements of electrode material and performance have been put forward . The properties of lanthanum tungsten electrodes are superior to thorium tungsten electrode and cerium tungsten electrode which is one of the most widely used electrodes.

Lanthanum tungsten electrodes have good mechanical cutting performance, creep resistance, ductility and high recrystallization temperature is currently the most popular electrode. It was developed from the European country in the 1980’s to replace thorium tungsten electrode. The tip colors of lanthanum tungsten electrodes are varies which depend on the amount of lanthanum oxide (La2O3) doping. When La2O3 doping amount is 0.80 to 1.20%, the tip color is black; when La2O3 doping amount is 1.30 to 1.70%, the tip color is golden yellow; when La2O3 doping amount is 1.80 to 2.20%, the tip color is sky blue.

Lanthanum tungsten electrode is mainly used in DC welding and AC welding. The experiment found that the 1.5% lanthanum oxide content in lanthanum tungsten electrode has similar conductive properties with thorium tungsten electrode which has 2% thorium oxide content. Besides, the burn rate of lanthanum tungsten electrode is smaller and has longer service life. On the other hand, lanthanum tungsten electrode is a non-polluting, non-radioactive green electrode. So it concern in European countries and Japan is very high.

Lanthanum tungsten electrode production method:

1. Add the appropriate amount of La2O3 powder into tungsten trioxide powder, after twice reduction to give W-La2O3 powder. The first reduction temperature is at 600 ~ 700 ℃and time is about 2 to 3 hours; the second reduction temperature is controlled at 800 ~ 970 ℃ and the hydrogen flow is 0.5-2.0m3 / h.

2. After pressing, swaging, stretching, straightening, polishing and other processes obtains the desired electrode rod.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Gold-plated Tungsten Cakes

- Details

- Category: Tungsten Information

- Published on Thursday, 21 January 2016 17:02

- Written by yaqing

- Hits: 290

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Cerium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 21 January 2016 17:14

- Written by yiping

- Hits: 256

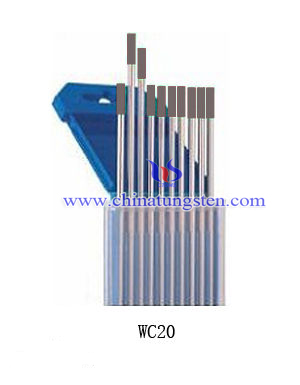

With argon arc welding, plasma welding, cutting, spraying technology continues to update and development, the requirement of electrode materials are increasingly high. In 1972, China first time success developed cerium tungsten electrode, which has a non-radioactive, low-melting, high thermal electron emission ability, arc stability, heat concentration, long life, easy to maintain the shape of the tip and other good properties. What’s more, it can replace thorium tungsten electrodes which has radioactivity.

Cerium tungsten electrode is kind of rare earth tungsten electrodes which added 2% cerium oxide (CeO) into tungsten matrix electrode product production by powder metallurgy, rolling, grinding and polishing and other processes. It is mainly used in low current DC welding, because it has a good arc and welding properties. On the other hand, cerium tungsten usually uses in welded pipes, stainless steel products and small parts welding. Cerium tungsten electrode is not suitable for use in high current conditions, because at high currents cerium oxide will quickly move to the high heat zones, namely the tip of electrode welding, causing cerium oxide uniformity damage. Uniformity of cerium oxide is an important influence factor affecting properties of cerium tungsten electrode, therefore cerium tungsten electrodes is not suitable for high current conditions.

Cerium tungsten electrode material properties are as follows: the work function: 2% Ce-W2.4ev; α-ray dose: 2% Ce-W2.42 × 10-5 curie / kg; oxidation resistance: high oxidation resistance.

Cerium tungsten electrode arc performance: the cathode voltage drop: 2% Ce-W12.0V; cathode spot: the cathode spot and service life are closely linked and it has small cathode spot and loss; electrode emission current density: higher; minimum arc voltage: 12V.

Cerium tungsten electrodes application performance: the burning rate: low; reliability of repeatedly arc and loss rate: arc stability, low loss rate; weld penetration: good.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

CVD Diamond Coated Carbide Pretreatment—Transition Applied (2/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 21 January 2016 17:00

- Written by xiaobin

- Hits: 219

The first part mainly describes the concept and the function of transition layer, this part we introduce some experiments about it. Related researchers certain related technology by using titanium (Ti) and nitrogen (N) ion and the substrate to produce a large number gradually decreased reaction TiCN N ions, so that transition layer containing C, N decrement amount to the surface direction, until the final surface titanium This is to the surface at the time of planting, diamond crystals partially reacted with a titanium Ti titanium carbide TiC, as part of the process of diamond film deposition seed, in order to improve the bonding strength between the diamond film and the buffer layer and the diamond nucleation density; some studies have found that uses TiN and TiCN deposition as the transition layer, it will make diamond film with high purity, but the speed of nucleation is slow. Therefore, they attempt to directly deposited on the surface layer of aluminum carbide substrate, or discontinuous deposit a certain amount of diamond grains, thereby improving the imbalance in thermal expansion coefficient between the TiN / TiC and diamond, making the diamond and speed and adhesion have been significantly improved.

Relevant foreign scholars have used plasma pulsed laser melting method in cemented carbide substrate surface layer of boron nitride (BN) film, which not only eliminates the adverse effects of cobalt Co brought, and significantly improve the binding force between diamond coating layer and tungsten carbide matrix. In addition, Chinese scholars are based on chromium carbide buffer layer deposition CVD diamond coating, and spectral analysis by SEM showed that the deposition process have a more significant impact on the diamond's shape and composition, and ultimately to the complete crystalline, less non-diamond ingredients with carbide substrate binding tightly CVD diamond coating.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com