Soft Scrap Containing Tungsten Used for Producing Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 January 2016 17:13

- Written by chunyan

- Hits: 249

The two traditional ways for recycling soft scrap containing tungsten are as follows:

1.Turn the wastes into sodium tungstate solution by cooking with NaOH, crystallize sodium tungstate crystal; then dissolve the crystal in circulating mother liquor and rebuild sodium tungstate solution, extract tungsten and purify to get ammonium tungstate, get ammonium paratungstate by evaporation at last.

2.Recover by method of ion exchange. First of all, acidify the mother liquor (adjust pH), then adsorb tungsten in mother liquor by using ion exchange resin with weak alkali macroporous. To generate ammonium paratungstate, ammonium chloride and hydrolysis are used in ion exchange process to get sodium tungstate solution, and finally get ammonium paratungstate by evaporate.

For shorten the process and increasing the recovery rate of tungsten, reducing production cost and preventing the environment pollution, a new method to recycle was puts forward, the specific steps are like below:

1. Ammonia leaching with pressure: mix soft scrap containing tungsten which is produced in Tungsten Hydrometallurgy smelting process with dilute ammonia in the environment of 0.2~0.6MPa and 120~200℃ for 1~3 hours; the molar ratio of NH3 in dilute ammonia and WO3 in soft scrap containing tungsten ratio is 2.5~4.5:1;

2. Filter to remove the slag: send the feed liquid generated in step 1 by leaching reaction into filter to remove slag;

3. Crystallization and separation: crystallize the solution which is obtained from step 2 in a evaporator at temperature 50~100℃ until the slurry density reach to1.02~1.10g/ml, finally we get APT crystal by solid-liquid separation.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Methods for Dealing with W-Mo Slag in Ammonium Paratungstate Production

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 January 2016 17:09

- Written by chunyan

- Hits: 275

High-quality tungsten mine is becoming less due to the continuing exploitation of tungsten resources in recent years, and tungsten ore with high content of molybdenum will be the main raw material of tungsten metallurgy, this would be bound to bring great negative. With the rising price of tungsten and molybdenum products, reasonable comprehensive use W-Mo Slag generated in the production of ammonium paratungstate (APT), not only can create profits to enterprise resource reuse, but also create wealth for the country.

The methods for dealing with the sulfided W-Mo Slag in APT production process at present are as follows:

1. Sell to molybdenum manufacturers in the form of deputy products for single recovery, this method will do no good to tungsten reuse to a large extent;

2. The sulfided molybdenum slag return to ball grounding process to accompany with the tungsten concentrates material.

The disadvantage of this method is:

1) Increase the treatment cost of ball grounding and ion exchange process, the content of tungsten in the slag can not be controlled effectively;

2) A large amount of impurities elements in the molybdenum slag will damage to the resin in ion exchange process thus easily cause resin poisoning, and bring larger economic loss;

3) It is not conducive to effective recycling molybdenum because large number it leaved in tungsten slag and dealt as waste;

4) Increase the labor intensity of workers.

3. Dissolve sulfided W-Mo slag generated in APT production into ammonia, inlet water vapor into pot made by titanium crystal, filtering and cooling after reaction, sulfide the filtrate for removing molybdenum, and qualified APT and slag containing with molybdenum obtained.

The advantages of this method lie in:

1) Effective use of resources and reduce the environmental pollution of ammonia;

2) Enrich molybdenum effectively and provide a good raw material for downstream industries, thus make full use of valuable resources.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nano-crystalline Diamond Coated Carbide Ball Description (1/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 January 2016 17:02

- Written by xiaobin

- Hits: 256

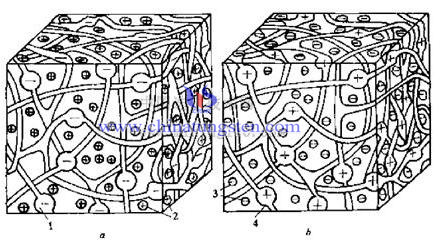

Nano-crystalline diamond coating usually used in plane, the sphere or curve like tungsten carbide ball requires some new process, which is different from conventional chemical vapor deposition (CVD) and physical vapor deposition (PVD). Based on the conventional process, new processes adapt to broader prospect according to the difference of physical properties, chemical properties, and shape or surface characteristics, such as microwave plasma chemical vapor deposition (MPCVD, deposits nano-crystalline diamond film with silicon substrate at 750℃.), hot filament chemical vapor deposition (HFCVD, it can fabricate spherical diamond film with 3μm of thickness), direct current arc plasma jet (it manage to prepare spherical diamond film on molybdenum substrate, which thickness is more than 500μm.)

The significance of nano-crystalline diamond coating on cemented carbide ball is that it can effectively reduce the abrasion of mechanical equipment components, which is also the direct reason of some mechanical parts failure. With the development of technology, the requirements of conditions of mechanical equipment are becoming strict, such as ultra-high temperature or ultra-low temperature, high load and high vacuum degree, which brings great difficulties to the mechanical equipments. If only depends on conventional lubricant grease, it is hard to adapt to the requirements at present which provides broad developing space for solid lubricant.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nano-crystalline Diamond Coated Carbide Ball Description (2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 January 2016 17:03

- Written by xiaobin

- Hits: 247

Generally, solid lubricant can be specifically divided into 3 types, solid powder lubricant, solid lubricant film and self lubricating composite material. Today has been successfully put into production solid lubricant film are tungsten diselenide (WSe2), boron nitride (BN), molybdenum disulfide (MoS2), gold (Au), silver (Ag), lead (Pb), etc. While nano-crystalline diamond films belong to one solid lubricant film, it has a high hardness, low friction coefficient, good chemical stability, high thermal conductivity and high modulus of elasticity so that it has a broad application prospect. Nano-crystalline diamond films are typical “cauliflower” structure with average grain size of 10-20 nm and homogeneous thickness around a sphere. The surface roughness increases with growing of film thickness. Mechanical properties of nano-crystalline diamond films were also tested by nano-indentation. The hardness and elastic modulus are about 40 GPa and 50 GPa, respectively.

In addition, Nano-crystalline diamond solid lubricant film can be applied to a number of pharmaceutical machinery, ball bearings, ball bearings present these are mostly silicon nitride (SiN) ceramic materials, etc., which would make the cost high the lack of elastic modulus and wear resistance and other properties. If we directly choose tungsten carbide ball with lower price, it can decrease the production cost, but the composition containing tungsten carbide ball of W, Co cobalt and other heavy metals, the event will wear the metals penetrate contaminated drugs, endangering patients and health. Therefore, solid nano-crystalline diamond films on the one hand to enhance the hardness of ball bearings, wear resistance and service life, a small part of the toner layer on the other hand nano-crystalline diamond worn infiltrated harmful to human health is extremely small, almost negligible.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

What Is Tungsten Ring(2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 January 2016 16:27

- Written by yaqing

- Hits: 233

| Tungsten Jewellery Supplier: Chinatungsten Online tungsten-jewellery.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com