Sensitizing Tungsten Trioxide Surface Enhancing Photoelectric Conversion

- Details

- Category: Tungsten Information

- Published on Monday, 01 February 2016 16:32

- Written by qiongyao

- Hits: 273

The use of surface sensitized method to improve the photoelectric conversion efficiency. The material must be supported on tungsten trioxide (WO3) semiconductor surface, thereby improving the light absorption and conversion capabilities. The surface sensitized principle is quite similar to semiconductor composite, but the light absorption by the conversion of primary tungsten oxide material turn into photosensitizer and photosensitizer, which must meet two requirements: (1) the band gap must is less than WO3; (2) the position of conduction band generally lost WO3 conduction band. It has now been found to meet the conditions by using a semiconductor mainly Fe2O3, Cu2O, CdS, etc.

The use of surface sensitized method to improve the photoelectric conversion efficiency. The material must be supported on tungsten trioxide (WO3) semiconductor surface, thereby improving the light absorption and conversion capabilities. The surface sensitized principle is quite similar to semiconductor composite, but the light absorption by the conversion of primary tungsten oxide material turn into photosensitizer and photosensitizer, which must meet two requirements: (1) the band gap must is less than WO3; (2) the position of conduction band generally lost WO3 conduction band. It has now been found to meet the conditions by using a semiconductor mainly Fe2O3, Cu2O, CdS, etc.

Semiconductor composite improves the photoelectric conversion performance of WO3. Semiconductor composite are two or more semiconductors by physical or chemical combination, which is relatively common, particular way of effectively to enhance the performance of the material. In order to improve the photoelectric conversion performance, composite machine generally is used as metal oxide, in short, which enables the photo-generated electrons or holes by compound semiconductors. It is gathered in two semiconductor conduction band or the valence band, so that electron and hole separated, thus improving the photoelectric conversion efficiency. In order to enhance the photoelectric conversion efficiency of the semiconductor, the use of metal oxides also using probability electron transfer media, which can improve the speed of migration of electrons in semiconductor material while reducing green light to stay in the complex.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Increasing Tungsten Trioxide Surface Energy Improving Photoelectric Conversion

- Details

- Category: Tungsten Information

- Published on Monday, 01 February 2016 16:21

- Written by qiongyao

- Hits: 286

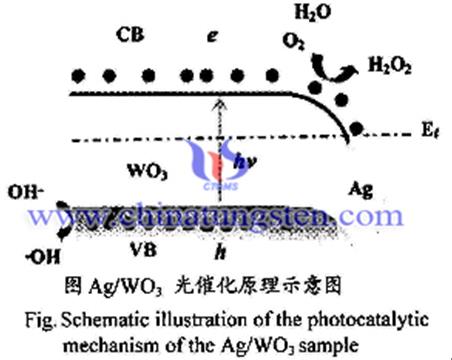

Improving photoelectric properties by taking precious metals surface as loading energy of tungsten trioxide (WO3) . The more common ways for noble metal are sputtering, deposition light, liquid adsorption, hydrogen reduction and the boron compound pulse electrodeposition method. And many scholars have reported the use of more precious metals deposited on WO3 surface together or sequentially deposited using hierarchical manner. Scholars found that when the load is metal Ag, optical and electrical properties of WO3 most is obvious, when the light irradiating on the surface of WO3, electron energy will start to give the valence band to the conduction band, and then migrate to the Ag nanoparticles on the light-generated electron-rich, lower electron - hole recombination probability.

Improving photoelectric properties by taking precious metals surface as loading energy of tungsten trioxide (WO3) . The more common ways for noble metal are sputtering, deposition light, liquid adsorption, hydrogen reduction and the boron compound pulse electrodeposition method. And many scholars have reported the use of more precious metals deposited on WO3 surface together or sequentially deposited using hierarchical manner. Scholars found that when the load is metal Ag, optical and electrical properties of WO3 most is obvious, when the light irradiating on the surface of WO3, electron energy will start to give the valence band to the conduction band, and then migrate to the Ag nanoparticles on the light-generated electron-rich, lower electron - hole recombination probability.

Dopant ions can increase the photoelectric properties of WO3. Ion doping is mainly accessed through the cation and anion inside the lattice to WO3, WO3 semiconductor substitution of W + W O2- ions or oxygen ions to affect the electron excitation and electron - hole separation. The study shows doping Cr, Mo equivalent of these metal replacement lattice W atom, not only is small on the geometry of the lattice, but also the bottom of the conduction band reduce the band gap; when the doping Ti, Zr, Hf, W is less than the valence state of the metal . Oxygen vacancies, oxygen vacancies are formed. The W atoms will cause the bottom of the conduction band of the shift because the band gap decreased from doping on the whole.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Prepare Phosphato-Tungstic Acid from Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Friday, 29 January 2016 19:42

- Written by chunyan

- Hits: 287

A method for preparing phosphato-tungstic acid by using ammonium paratungstate as raw material is proposed in this paper. The principle is: ammonium paratungstate reacts with inorganic acid to get a reactive acid precipitation, and then contacts with phosphoric acid to obtain phosphato-tungstic acid solution, crystallize and we get phosphato-tungstic acid crystal.

Specific steps are as follows:

1. Ammonium paratungstate reacts with inorganic acid to get a reactive acid precipitation;

Inorganic acid can be hydrochloric, sulfuric, nitric or hydrochloric acid, sulfuric acid and nitric acid can mix at any volume ratio, the appropriate concentration of 0.2 mol/L~6.0mol/L; the amount is optional, as long as active precipitation of phosphato-tungstic acid is able to generated; the reasonable temperature is10 ~ 40℃; reaction time for 2~5 hours;

2. Active precipitation of phosphato-tungstic acid reacts with excessive phosphoric acid solution, and get phosphato-tungstic acid solution;

3. Precipitate phosphate acid from the solution, drying and crystallizing to get the crystal.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Intermediate Compound of Tungsten - Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Friday, 29 January 2016 19:45

- Written by chunyan

- Hits: 260

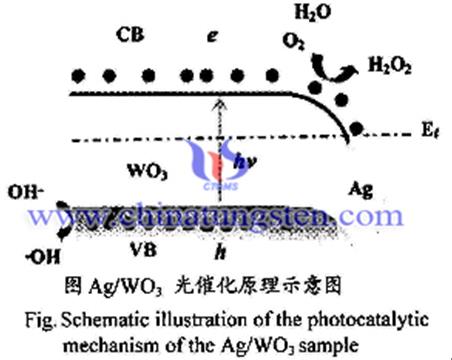

Ammonium paratungstate (APT) is a primary product of tungsten, which is an important raw material for the manufacture of tungsten products and hard alloy. Also it’s the most common tungsten compound, and widely used in tungsten smelting. The quality of APT determines properties and quality of tungsten products in a large extent. WO3, blue tungsten oxide, tungsten acid, ammonium metatungstate can be generated through partly or completely heating. APT is a white transparent crystal with good loose and mobility. APT will begin to loose ammonia when heated in the air up to 60℃, begin to dehydration at 100℃, and begin to turn into yellow tungsten oxide at 450℃. APT is completely converted into blue tungsten oxide When heated to 300℃ in hydrogen, and turned into violet tungsten at 400℃, trioxide at 500 to 600℃, and turned into tungsten powder when the temperature reach to 600~900℃.

APT crystal powder can be prepared by evaporation of ammonium tungstate solution, the temperature supposed to be generally controlled at more than 50℃, and its particle size and composition changes with the temperature:

1. Evaporation and crystallization 80~100℃, APT present as flake crystal with 5 molecules of crystal water;

2. when the temperature is below 50℃, APT present as fine white needle crystal with 11 molecules of crystal water.

The number of water in APT crystal decided by the production conditions, and the solubility increased with temperature increasing. Heating the APT with high impurities content to get decomposition products, and then dissolve in ammonia solution, and heated at the same time, evaporate and crystallize, round cycle 1~2 times or more, then get high purity APT.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Wire Production Processes

- Details

- Category: Tungsten Information

- Published on Friday, 29 January 2016 17:56

- Written by yiping

- Hits: 257

Tungsten wire resistivity is 5.3 * 10 ^ -8, which has a high melting point, high resistivity, good strength, low vapor pressure and other excellent performance. Tungsten wire has many different species, including black tungsten wire, white tungsten wire, stranded tungsten wire, doped tungsten wire, tungsten rhenium wire and tungsten filament and so on. It is widely used in the field of electric light sources, the main application is used for create filament and high-speed cutting steel. On the other hand, it also can be used in the field of optical and chemical instruments.

Tungsten production processes are as follows:

1. ammonium paratungstate (APT) as a raw material, which was calcined in air at about 500 ℃ to obtain tungsten trioxide.

2. Doped a certain amount of potassium oxide hydroxide, silicon oxide and aluminum oxide into tungsten trioxide, wherein the total amount of the three types doped oxide is not more than 1%, then the powder is mixed uniformly.

3. Proceeded two-steps reduction, the first step is at about 630 ℃ restore tungsten oxide to tungsten dioxide, and then at about 820 ℃ restore tungsten dioxide to tungsten powder. The purpose two-step reduction is to make potassium which is doped into tungsten powder can fully play its role, but also two-step reduction can better control the particle size of the powder.

4. Placed restored doped tungsten powder in a special mold pressed into elongate square bars. The square bars are placed in hydrogen to electrify which is using and is using resistance heating method for sintering.

5. Swaging processing, sintered tungsten bar after swaging processing become about 3mm diameter tungsten rod, then drawing by wire-drawing die so its diameter becomes finer. Tungsten rods are drawing and lubrication by tungsten carbide wire-drawing die or diamond wire-drawing die, eventually processed into different thickness of the tungsten wire.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com