Tungsten Carbide Ball V-slot Grinding (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 29 January 2016 17:45

- Written by xiaobin

- Hits: 279

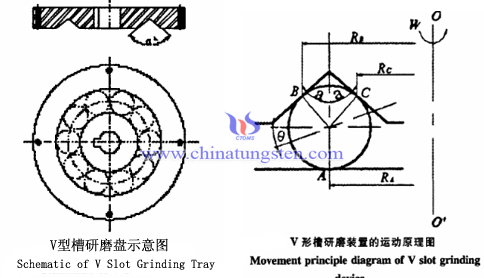

There are many influencing factors of the grinding precision and efficiency of tungsten carbide ball, such as the material of tray, grinding slot, grinding fluid, the conditions and other grinding parameters, and the shape of grinding slot of the grinding tray is the most significant factor of the effect on the precision and efficiency of tungsten carbide ball. First of all, V-slot combined with carbide ball brittle, intolerance bump features and designed its angle according to the diameter of the sphere can make adjustments to the common angle is generally 45 °, 60 °, 90 °,120°.

Then placed on concentric groove ball blank disc between the two, so that in the state's three-point contact, under pressure, viscous force by rotating grinding disc friction and grinding fluid movement along the groove plate. The rotating tray, tungsten carbide ball, the fixed tray and grinding compound have interaction, which forms high pair (deputy campaign by two members point or line contact constituted collectively referred to as high pair.) between ball and the surface of tray groove. Finally, the blank balls extruded and wore to remove the finish allowance of the surface and ball milled gradually. The schematic of V-slot grinding tray and the movement principle diagram of V-slot grinding are given as follow:

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com