Effect of Tungsten Powder Granularity on Tungsten Copper Micro-structure

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:03

- Written by xiaobin

- Hits: 263

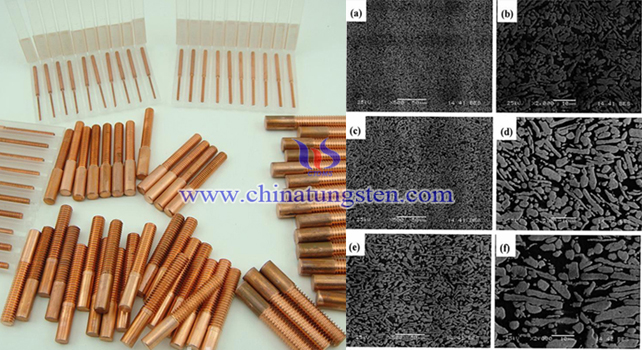

Similarly takes tungsten copper W-30Cu electrode as an example, compared with tungsten copper electrode by tungsten powder with different granularities at the same temperature SEM pictures, we can find that tungsten copper W-30Cu electrode with similar composites, the smaller the particle size of the tungsten powder, tungsten powder dispersed more evenly, but the greater the possibility of the obturator and defects, W grain size is uneven, resulting in an overall lower uniformity; on the contrary, the larger the tungsten powder particle granularity, the greater the corresponding grain size, dispersibility of the tungsten particles is reduced, the connection between the tungsten particles is weakened so that the amount of bores decreased. The following are the different particle size of tungsten powder prepared W-30Cu tungsten copper alloy electrodes SEM photograph, from left to right are the tungsten powder particle size (a) and (b) -2.9μm, (c) and (d) -4.2 -4.8μm, (e) and (f) -11-13μm:

Theoretically, the porosity of tungsten copper W-30Cu with smaller granularity is smaller than the coarser one at the same sintering temperature. This is due to in the process of sintering (surface diffusion plays an leading role at 1350℃ sintering temperature) with the decreasing granularity of powder, the free energy will increase, which further promotes the sintering processing. While interconnected particles occurs first in the surface of the particles.

The finer the grain size of tungsten powder, which means larger specific surface area, active surface atoms, the more the (surface energy increases), so that the surface diffusion easier to carry out. Reduced powder size is also thought to increase the diffusion of the interface between the particles, and to shorten the diffusion path, thus increasing the number of atoms per unit time-proliferation. In addition, the granularity too coarse to cause uneven tungsten skeleton bores and lead to the appearance of copper enrichment after the infiltration; and the particle size is too prone to particle agglomeration Details such tungsten skeleton prone channel closed or blocked, leading to infiltration of liquid copper is difficult to completely infiltrated, leaving part of the pores in the products, so that the uneven distribution of tissue composition of the product. Therefore, the granularity and the combination of the granularity has an remarkable influence on infiltration process.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Effect of Tungsten Powder Granularity on Tungsten Copper Density

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:00

- Written by xiaobin

- Hits: 258

The granularity of tungsten powder plays an important role in the comprehensive properties, such as the hardness, the density, the electrical conductivity and micro-structure and so on. Here we are concentrated on the effect of tungsten powder granularity on the density of tungsten copper electrode.

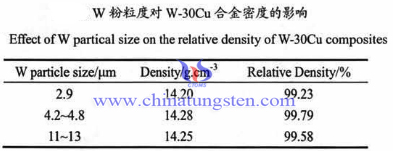

Take W-30Cu tungsten copper electrode as an example, there is sheet of effect of the granularity of W particle on the relative density of W-30Cu tungsten copper electrode (different size, includes 2.9μm, 4.2-4.8μm and 11-13μm) as follow:

Theoretically, the granularity of tungsten powder is one of the main factors of the effect of tungsten copper electrode structure and properties. Viewed from the sheet, we can see that the experiment were used Fibonacci particle size of 2.9μm, 4.2-4.8μm and 11-13μm tungsten powder by pressing, infiltration and other technology to prepare W-30Cu tungsten copper electrodes. Several tungsten powder (W) sizes of the resulting tungsten copper alloy electrical extreme density in 14g / cm3 or more, relative density has reached more than 99%, when the tungsten powder particle size 4.2-4.8μm, the relative density of up to about 99.79%, and when the tungsten powder particle size is small about 2.9μm, relative density or lower density, relative density of about 99.13%.

Generally, the smaller granularity of tungsten powder, the smaller capillary radius and the higher liquid metal increases, it is more beneficial for the infiltration processing. However, finer tungsten powder has larger specific area and higher energy of surface, which internal close bores of the porous tungsten skeleton will increase and the liquid metal (copper, Cu) is difficult to penetrate. In addition, the finer the particle size of the tungsten powder, tungsten copper alloy tungsten particle size is smaller, the possibility of greater obturator and defects, tungsten copper electrode so that the uniformity of the overall organization is also affected. Therefore, selecting a moderate size tungsten powder is more suitable for tungsten copper alloy electrode production and processing.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Gold-plated Tungsten Birthday Block of Monkey Year

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 16:14

- Written by yaqing

- Hits: 258

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Chinese Zodiac Gold-plated Tungsten Blocks

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 16:17

- Written by yaqing

- Hits: 271

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Dirty Bomb Shielding Container(2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 16:12

- Written by yaqing

- Hits: 244

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com