Tungsten Copper Contacts With CeO2 Density

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:34

- Written by Yahong

- Hits: 358

Whether adding rare earth or rare earth oxides to tungsten copper contacts, Cu20W80’s density decrease as the increase of additive amount. Theoretically, the density of Cu20W80 is 15.64g / cm³, is higher than the density of Ce and CeO2, the density of Ce is 6.77 g / cm³, and the density of CeO2 is 7.10 g / cm³, therefore, if the additive amount of rare earth or rare earth oxide is larger, the density of tungsten copper contacts sample will be lower.

As can be seen from the analysis of the experimental results, density test results and analysis of the influence of rare earth (Ce) on Cu20W80 performance are as follows:

When Ce is added in an amount of 1%, the density of the sample decline significantly; when its amount is from 1% to 3%, the density does not decline substantially; the actual density is higher relatively when the density is of 3%, which can be considered the optimum amount of Ce. Density test results and analysis of the influence of rare earth oxide (CeO2) on Cu20W80 performance are as follows:

The density of Cu20W80 decrease unevenly and its trend is dramatic, which significantly decrease with the increase of the amount of CeO2, however, when its content is from 5% to10 %, the change trend of density is relatively flat, and upward slightly. In summary, adding rare element tungsten copper contact is better than rare earth oxide, and its optimal addition amount is of 1% -3%.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Comparative Experiment of Ce and CeO2 on Tungsten Copper Contacts Properties

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:32

- Written by Yahong

- Hits: 331

Experimental materials: tungsten powder (purity: 99.9%, average particle size: 6-8μm), copper powder (74μm), rare earth elemental Ce (massive, purity: ≥99.95%), rare earth oxide CeO2 (powder, purity: 99.9 %)

Experimental procedure:

Mixing powder --- because at room temperature, Ce is easily oxidized, therefore, CeO2powder can be directly mixed with copper and tungsten powder, whereas Ce and copper are added by Infiltration into tungsten blanks.

Pressing --- Pressing, under the pressure of 600MPa, the two mixed powders, preparing a size of 14㎜ * 10mm blanks.

Infiltration --- using infiltration method under the condition of nitrogen protection, temperature is of 1350 ℃ or so, infiltration holding time of 2h, ultimately preparing the tungsten copper contacts by adding Ce rare elemental and tungsten copper contacts by adding rare earth oxide CeO2, making use of relevant experimental apparatus to get experimental results.

Observing results:

Use HB-3000 Brinell hardness tester to measure hardness. Use ESJ200-4 electronic analytical balance to measure density, which is based on "Experimental Methods of Contact Materials" in GB / T5586-1998. Use 7501-type eddy current conductivity meter to measure conductivity measurements. Use Nephot -II type metallurgical microscope to observe tissue morphology. The qualitative analysis of the composition is measured by using the XRD-700 X-ray diffraction to analyze the sintering samples. And then compare the results.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Contact Preparation of Tungsten Copper Contacts (Cu80W / Cu)

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:30

- Written by Yahong

- Hits: 374

1. Selection of raw materials of tungsten copper contacts (Cu80W / Cu)

(1) Selection of tungsten powder. Select tungsten powder with the grade of FW-1 standard, tungsten powder particle size range is: 6-8μm. If the tungsten powder is oxidized, then the reduction of the oxidized tungsten powder is needed at the condition of hydrogen protection, and at a temperature of about 860 ℃, and holding 1h.

(2) Selection of copper powder. Adopting electrolytic copper method to obtain copper, which should be restored firstly, its reducing atmosphere is hydrogen atmosphere, temperature is about 300 ℃, holding time of 1h.

2. Preparation of contact

Preparation of contact of tungsten copper contacts (Cu80W / Cu) adopts sintering and infiltration process of powder metallurgy.

Process:

Mixing powder (tungsten powder and copper powder, in accordance with an appropriate proportion) → pressing to its shape → sintering and infiltration (tungsten copper blanks) → machining and squeezing.

Sintering and infiltration conditions: the need for introducing hydrogen (hydrogen flow: 1m³ / h), the temperature is about 1500 ℃, sintering time is 2h.

Machining and squeezing: machining the tungsten copper blanks after sintering and infiltration, and then, coating its surface with oil evenly, then squeezing by using four-column hydraulic press machine.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

A Primary Algorithm of Tungsten Ore Based on SUSAN Operator

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:15

- Written by xinyi

- Hits: 354

Tungsten primary machine to achieve automatic sorting system is the key technology of tungsten ore image featureextraction,identification and sorting algorithm.SUSAN operator to improved fast algorithm as the core of tungsten ores and primary algorithm is a targeted optimum algorithm.A primary algorithm of tungsten ore based on SUSAN operator is designed and realized.The algorithm adopts the improved SUSAN edge extraction operator with morphological opening operation to estimate background and global gray image taking the original geometry of complex operations to weaken the background noise on the image texture and the influence.In order to improve the effect of edge detection,the algorithm is combined with the similarity SUSAN comparison based on image gray edge detection algorithm.The algorithm,which does not require gradient calculations,is simple,accurate in positioning and antinoise.The effect of edge detection is enhanced.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Determination of Tungsten in Tungsten Ore by Spectrophotometry with Microwave Digestion

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:13

- Written by xinyi

- Hits: 365

Microvave digestion method was applied in the determination of tungsten in tungsten ore by thiocyanate spectrophotometry.The digestion solvent was 40 mL of NaOH solution(25 g/L).The microwave power was medium-high level.The digestion time was 30 min.The dosages of all reagents were investigated.The detection limit of this method was 0.5 μg/mL.The tungsten ore was analyzed by the proposed method and the determination results were consistent with those obtained by the traditional sample preparation methods.The relative standard deviation(RSD) was less than 2.3 %.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Experiment Study of Tungsten Ore from Primary Slimes

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:05

- Written by xinyi

- Hits: 327

The new type centrifugal separator was used to discarding the large number of tailings of tungsten ore from slims,and the next is that the gravity separation concentrate was put into the process of flotation.Of these mine samples,the degree of slimings is high and the particle size is very low,therefore the separation is very difficult.The experiment test through a flotation flowsheet of centrifugal-flotation was performed.The tungsten concentrate with the grade of 34.74 %WO3,and the total recovery of 75.21% can be obtained.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

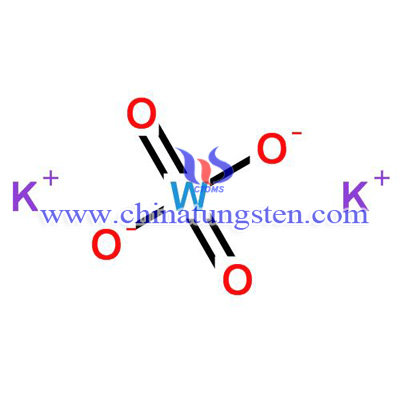

Potassium Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 15:52

- Written by xiaoshan

- Hits: 399

Potassium tungstate is white or colorless crystalline powder and is a monoclinic structure. Its physical properties are as follows: chemical formula: K2O4W, molecular weight: 326.0342, density: 3.12g/ml, melting point: 921 ℃, Solubility: soluble in water, insoluble in alcohol. K2O4W should be sealed in the storage vessel, and it is placed in a cool, dry place. Besides avoids contact with tungsten oxide, moisture or humidity. In addition, it is harm for the water, if there is no relevant government departments permission shouldn’t released to the surrounding.

Potassium tungstate is mainly used in analytical reagents, alkaloids precipitant, but also for the fine tungsten and bronze manufacture.

Potassium tungstate producing processes are as follows:

1.Mixed potassium dichromate (K2Cr2O7) with tungsten powder, after reaction to obtain potassium tungstate and chromium oxide.

2.W react with KOH to produce potassium tungstate.

W reacts with KOH solution, if no oxygen participate there is a slight reaction. But the reaction has oxidizing agent (such as KNO3, KNO2, KClO3, PbO2, etc.) will cause violet reaction.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

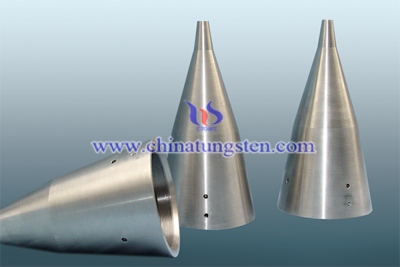

Medical Tungsten Alloy Radiation Shielding Material Series

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 11:53

- Written by Cher

- Hits: 358

1. Tungsten alloy multi-blade grating with the thickness of 2.0 to 3.8mm and the plate flatness of 0.05mm.

2. Tungsten alloy protective tank for medical radiation shielding walls, shielded syringe for the shielding of medical radioactive liquor, and tungsten alloy memory for containers such as pots and tanks used for storing radioactive substances

3. Collimator for medical linear accelerators and cyclotrons

4. Shielding device for the shielding of rays of 60Co therapy apparatus.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

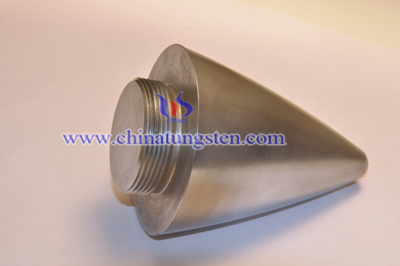

Tungsten Alloy Counterweight

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 11:31

- Written by Cher

- Hits: 385

The tungsten alloy counterweight is formed by adding elements such as Fe, Ni, Cu, Co, Mo and Cr into tungsten serving as the matrix (the content of W is 85 to 99 percent). Tungsten alloy called high density alloy because its density is up to 16.5 to 19.0g/cm3. It also has the characteristics of high specific gravity, high strength, strong ray absorption capability, high thermal conductivity, small thermal expansion coefficient, good electrical conductivity, and good weldability and machinability, wherein the specific gravity is usually 16.5 to 18.75g/cm3; the tensile strength is 700 to 1,000Mpa; the ray absorption capability is 30 to 40 percent higher than that of lead; the thermal conductivity is 5 times that of mould steel; and the thermal expansion coefficient is only one second to one third of that of Fe or steel. In view of its excellent functions, the high density alloy is widely applied to the industries of aerospace, aviation, war, oil drilling, electrical appliances and meters, medicine and so on.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

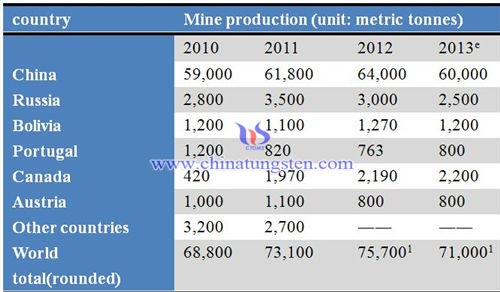

World Tungsten Mine Production

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 July 2015 17:05

- Written by xinyi

- Hits: 759

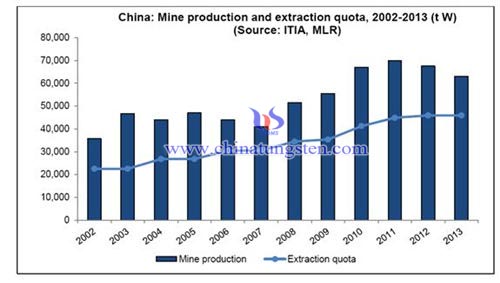

According to USGS, world tungsten mine production was estimated to be 71,000 tonnes in 2013. China was the largest producer in 2013, followed by Russia and Canada. The top three countries accounted for 91% of the total production in 2013. Other major producing countries include Bolivia, Austria and Portugal.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com