Tungsten Carbide Button Grades

- Details

- Category: Tungsten Information

- Published on Thursday, 23 July 2015 10:49

- Written by tang

- Hits: 379

As for the main national related brands, YK02 and YK10 own the hardness of 90.1and 88.8. They are mainly used for medium and small size carbide ball tooth for inlay system cone drill and impact drill, drilling in soft and hard rock, but it can also be used for other drilling alloy sheet; YK20.1 and YRK10 own the hardness of 88.8 and 88.5. They are mainly not only used as an alloy ball tooth for inlay system cone drill and impact drill column gear, medium-hard and hard rock drilling, but can also be used for other drilling alloy sheet; YG11C and YK50 own the hardness of 87.9 and 85. They are mainly used as an alloy ball tooth for inlay system cone drill and impact drill column gear, medium-hard and hard rock drilling, but can also be used for other drilling alloy sheet.

YG4C’s hardness is 90 and Mainly used for cutting soft and hard materials in the impact drill.

YG6’s hardness is 90.5 and is used as an electric drill, coal cutter, blade oil cone bit and button bits. YG8’s hardness is 89.5 and is used as a core drill, electric drill coal, coal cutter, drill and blade oil cone ball tooth bit. YG8C’s hardness is 88.5 and is mainly used for medium and small percussion drill bit of ball gear, and a rotation exploration drill pad. YG11C’s hardness is 86.5 and is most used percussion drill bit and drill bit cutters for cutting high hardness of the material sphere teeth. YG13C’s hardness is 86.5 and is Mainly used in rotary percussion drill bit for cutting high hardness of the material sphere teeth. YG15C’s hardness is 85.5 and is most used oil cone drill in hard rock and soft cut of the cutting tool.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Application

- Details

- Category: Tungsten Information

- Published on Thursday, 23 July 2015 10:47

- Written by tang

- Hits: 362

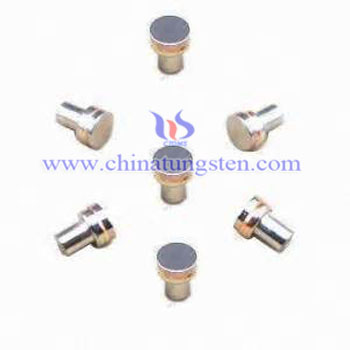

The main products of tungsten carbide button mainly contain dig way teeth, conical teeth, tooth edge wedge, flat tooth, wedge-shaped teeth, spherical tooth, spoon-shaped teeth, tooth mushrooms.

Carbide is the best material in tungsten carbide button widely applied in the production of high pressure DTH drilling industry.

Tungsten carbide button is widely used in petroleum drilling and snow removal equipment-snow plow. In addition, in the cutting tool tooth carbide ball and mining machinery, road maintenance and coal drilling tool, tungsten carbide button also has good application. Carbide button mining gear is mainly used as quarrying, mining and civil construction of tunnels and mining tools in the mine. Tungsten carbide button has its own unique performance. Therefor,it is widely used in petroleum drilling and snow removal, snow plow machines and other equipment. In the meantime, tungsten carbide button is also applied wildly for drilling, mining machinery, tools, and road sweeping snow removal and road maintenance tools. Tools quarrying, mining, tunnel engineering use, and civil construction.

Depending on the oil drilling machinery, such as cone bit, DTH drill, geological drilling tools, carbide button are divided into different standard styles: P-type flat-top position, Z-type coins ball position, X-type wedge position. Stability and high technology to ensure the high quality of our products, hard alloy ball tooth drilling tools are often used as Shearer, mining machinery tools and road maintenance tools for snow removal and road cleaning. Carbide ball mining gear also is widely used as a digging tool quarrying, mining, tunneling has civil buildings. In addition, as a drill accessories for heavy duty drills or deep hole drill tool accessories.

Tungsten carbide button with excellent wear resistance and toughness, compared with similar products with higher speed boring. Carbide button drill head series passivation long life cycle, which do not wear life is about the same diameter drill bit grinding times titles edge life of 5-6 times, will help save the auxiliary work, reduce workers' physical and speed up the pace.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Future Development

- Details

- Category: Tungsten Information

- Published on Thursday, 23 July 2015 10:37

- Written by tang

- Hits: 333

With the continued rapid development of the regulation of China's national economy, as well as an open market economy, The Chinese market is very active in tungsten carbide button. Here let’s follow carbide button gear manufacturers’ foot and take a look at the development of tungsten carbide button. In industries which need to use tungsten carbide button at home and abroad due to the use of objects and the use of technology and the use of different equipment, the quality and variety of carbide requirements are also different. So different varieties and quality grades of carbide products go through a circulation in China. Foreign high-grade carbide continue to enter the Chinese market, and China's production of various grades of carbide also continue to enter the overseas market. This phenomenon leads to such a result: supply is greater than demand, and market competition is very fierce.

In tungsten industry, the consumption of tungsten carbide is about 50% of the total consumption of tungsten content. Therefore, the development of industrial carbide tungsten plays a very important role on the development of the whole industry. Carbide is still widely used in life such as the military, aerospace, machining, metallurgy, oil drilling, mining tools, electronic communications, construction, etc.. Among these areas above, the requirements for hardness alloy is very high. Generally once the the tungsten carbide lack of alloy hardness, the resistance will be on the poor. Poor wear resistance properties will lead to lower efficiency in alloy among these areas.

Carbide enables the use of common alloy show the amount of damage reduction, and even can be said several times hardness of other alloy. From its high hardness characteristics, it is easy to see that other alloys is not comparable with tungsten carbide in market development.

In the future market, demand for tungsten carbide button will continue to increase. No matter in which country, carbide are part of a widespread use of steel, because its hardness can not be substituted by other steel products. As can be seen from the foregoing description, the development prospects of carbide is very good.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

English Cricket Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 17:38

- Written by yingying

- Hits: 339

English Cricket is a popular and challenging tungsten dart rule, this article will tell every details about English Cricket.

Number of Players: Two players or two teams

Numbers in Play: All numbers are used but since each score must exceed 40 the higher numbers especially 20 are the favorites.

Rules of Play: One player becomes the batter, and the other is the bowler; the batter goes first. Ten stripes are entered on the dartboard as wickets. The bowler's task is to erase these wickets by hitting bull's-eyes: With each single bull's-eye, one wicket is erased, and with each double bull's-eye, two wickets are erased. The batter's task is to score as many points or runs while any wickets remain, but only scores over 40 counts. For example, a score of 38 would score no runs, a score of 42 would score 1 run and a score of 60 would score 20 and so on.

Scoring stops when all 10 wickets are (or crossed out) by the bowler. The batter notes his or her final score on the scoreboard, and the roles are reversed. The game is played in two separate rounds, with each player throwing an entire round as batter and bowler. The winner is the player with the most points, or runs, from his or her round as batter.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Improve Tungsten Darts TechniqueⅡ

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 17:30

- Written by yingying

- Hits: 340

The most important tip for improving your tungsten darts technique is to always follow through with your throw. You should always have a nice long follow-through with the motion of your arm towards the dart board. See your hand end up where you want to hit the dartboard. This will create a smooth and natural throw that will allow you to gain consistency. With consistency, you'll be able to start throwing with more accuracy. Specifically, you want to keep your forearm fairly straight and extend your arm so that the follow-through is pointing your arm straight at the dart board.

Sometimes, the noise of the location in which you are playing tungsten darts will affect your performance. For example, if you are in a noisy bar, you may be distracted by your surroundings, or if you are playing with friends that make a lot of noise during a party. To help with this just imagine that you are at your home practicing playing darts to help you focus on your game and drown out the noise.

Now that you have a series of tips that you can work on to improve your technique, you can take the appropriate steps to improve your game of tungsten darts. It's always important to practice as much as time allows. To be good at anything it requires consistent practice and dedication.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Improve Tungsten Darts TechniqueⅠ

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 17:27

- Written by yingying

- Hits: 331

Trying to improve your tungsten darts technique when throwing darts? With these darts tips you will improve your technique when throwing.

One of the biggest things when learning how to throw tungsten darts and improving technique is to practice on a regular basis. To do so it is helpful to have a dartboard in your own home when throwing tungsten darts. This way whenever you have a free moment you can take some time to practice. It's ideal if you can set aside 30 minutes of practice each day to improve your darts technique.

One of the best ways to learn how to throw tungsten darts consistently is to learn how to throw with a rhythm. A lot of people struggle with consistency when throwing because they are rigid or they over think it when throwing a dart towards the dart board. Throwing at different speeds with different forces will cause inconsistencies in your technique. That's why it's important to find a smooth rhythm that will allow you to consistently repeat the same action over and over.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantage of Tungsten Gamma Knife

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:50

- Written by wenjing

- Hits: 336

Due to tungsten material has high density, excellent radiation attenuation properties, and environmental friendly, it is widely used to produce tungsten gamma knife. Removable 4, 8, 14, or 18mm tungsten collimators with circular apertures are used to create various size focal volumes in gamma knife. Modification of the target radiation dose distribution can be achieved using multiple target points with different collimators, or use of beam plugging, or different beam angles.

A significant advantage of tungsten gamma knife over other available radiological systems is the ability to create conformal and irregular dose plans using multiple tungsten target points. Highly conformal radiosurgery is crucial to maintain low side effect rates by tailoring the effect to the irregular 3D geometry of tungsten target volume; in addition tungsten gamma knife has high selectivity, meaning that the radiation dose falls off outside of the target very steeply, thereby reducing risk of injury to adjacent structures.

The picture below shows tungsten radiation shielding to produce gamma knife.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Polymer Substitution to Depleted Uranium

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:46

- Written by wenjing

- Hits: 358

Depleted uranium has a very high density and is primarily used as shielding material for other radioactive material as shielding in industrial radiography cameras. Depleted uranium is very dense; at 19,050 kg/m³, it is 1.67 times as dense as lead, but less dense than tungsten.

Due to its good performance of radiation shielding, tungsten has comparable radiation shielding ability as depleted uranium but is much healthier than depleted uranium. Many manufacturers, especially those in industry, are trying to replace depleted uranium radiation shielding products with tungsten polymer products. In additional, tungsten polymer has better flexibility and excellent workability than depleted uranium, tungsten polymer sheets can be cut or holed with household scissors and formed into shapes with various curved surfaces.. Tungsten polymer is low-toxicity, high-strength, high-density material can be substitution to depleted uranium for radiation shielding.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Contacts With CeO2 Hardness

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:38

- Written by Yahong

- Hits: 362

The hardness value of tungsten copper contacts (Cu20W80) by adding Ce is relatively large, and with the increase of amount, the hardness of the contacts does not change significantly, the reason is shown as follows:

Rare earth (Ce) and copper form the compound of CeCu6, its particles is hard and distributes in the matrix, which plays the role of dispersion strengthening. Adding a small amount of Ce not only can make grains fine, but play the role of grain refinement, in addition, the purification of Ce makes the binding force of copper atoms enhanced, and these factors make the hardness of tungsten copper contacts improved. However, if the additive amount is too much, Cu20W80 will produce large amounts of oxide inclusions, resulting in the decrease in hardness.

The hardness value of tungsten copper sample by adding CeO2 is small and the change is significant. Causes: What can be drawn from the results of density is that the density of sample adding rare earth oxide is generally low, this is the main reason of the hardness of sample is low when the additive amount is of 1% and 3% CeO2. And because there are many porous holes and there is agglomeration phenomenon in the sample tissue of 3% of the amount of CeO2, making hardness the minimum. As for the amount of 5% and 10% of the adding amount of CeO2, which have improved the hardness of the sample, which is due to the effect of a second phase strengthening.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Experimental Study on Mineral Separation of a Copper-Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Wednesday, 22 July 2015 16:37

- Written by xinyi

- Hits: 349

This article introduces the experimental study on mineral separation of a copper-tungsten ore.

Through the study of process mineralogy,ore chemical composition,mineral composition,pore-imbedding stains relationship,particle size distribution characteristics are identified.The process of preferential flotation of copper-heating cleaning of scheelite-gravity separation of wolframite with shaking table is adopted.As a result,better experimental indexes are achieved with copper recovery as 94.64 %,copper concentrate grade as 23.04 %,scheelite concentrate grade as 60.35 % and the total recovery of tungsten as 76.41 %.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com