Relationship between quality loss of arc erosion and arcing times of new tungsten copper contacts material

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 17:09

- Written by Yahong

- Hits: 344

New tungsten copper contacts material: tungsten copper contacts (with fibrous structure)

Sample 1: WCu30 prepared by mixing, sintering and other process;

Sample 2: fiber structure of tungsten copper contacts (Φ = 0.12mm);

Sample size: 10mm * 10mm * 10mm.

The arc erosion of new tungsten copper contacts material and WCu30 are increasing with the increase of arcing erosion. In the beginning, quality loss of arc erosion of both samples increase rapidly with the number of arcing time, then slowly increasing during 15-20 times, and then quickly increase after 30 times, besides, the quality loss of sample 2 is less than sample 1. The reason of quality loss increased rapidly of the two samples is: under the thermal action of discharge arc, the original burr, unevenness and impurities of the cathode material’s surface are suffering from strongly electron and ion sputtering, resulting in a large loss of material; since sample 2 is using tungsten fibers as its materials, which enhance its mechanical properties, so the strength and hardness of the material increases, and the loss can be reduced; the arc has played a role in it at the same time, the molten copper, due to capillary suction, can make melt filling in tungsten skeleton, such splash and losses of cathode materials can be reduced. Because the quality loss of Sample 2 is less than sample 1, so sample 1 with higher arc resistance to corrosion.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Classification of Tungsten Ores-II

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 16:33

- Written by xinyi

- Hits: 354

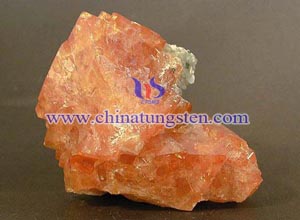

Tungsten ores

Tungsten does not occur naturally in its pure metallic state; rather, it is found in several ores, but only two kinds of tungsten-bearing mineral rocks, called wolframite and scheelite, are mined commercially. Wolframite accounts for about 70% of the total tungsten resources in the world, and scheelite accounts for about 30%.

Scheelite

Scheelite is a calcium tungstate mineral that forms a series with the rarer mineral powellite, which contains molybdenum in place of the tungsten. Colors include golden yellow, brownish green to dark brown, pinkish to reddish gray, orange and colorless. Transparency ranges from translucent to transparent and crystal faces are highly lustrous. Its gravity is high and its hardness is low. It also fluoresces under shortwave ultraviolet.

Scheelite occurs in contact metamorphic skarns, in high-temperature hydrothermal veins and greisens, and less commonly in granite pegmatites. Notable occurrences include Hollinger Mine, Ontario, Canada; Saxony, Germany; Tong Wha, Korea; Sonora, Mexico; Cornwall, England; New South Wales and Queensland, Australia; Mill City, Nevada, Atolia, San Bernardino Co., California, Cochise Co., Arizona, Utah and Colorado, all in the USA; and Jiangxi, Hunan and Yunnan provinces, China.

Scheelite is a subordinate ore of tungsten, with wolframite supplying a greater quantity on a worldwide basis. Scheelite is synthesized via the Czochralski process to produce the material that is used to imitate diamond, as a scintillator, or as a solid state lasing medium.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Classification of Tungsten Ores-I

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 16:29

- Written by xinyi

- Hits: 400

Tungsten ores

Tungsten does not occur naturally in its pure metallic state; rather, it is found in several ores, but only two kinds of tungsten-bearing mineral rocks, called wolframite and scheelite, are mined commercially. Wolframite accounts for about 70% of the total tungsten resources in the world, and scheelite accounts for about 30%.

Wolframite

Wolframite is not scientifically classified as an individual mineral species by the International Mineralogical Association (IMA). However, it is widely recognized as a mineral series, with the minerals huebnerite and ferberite being its end members. Huebnerite is the manganese rich end member while ferberite is the iron rich end member. Wolframite is a reddish-brown to grayish-black lustrous mineral which is the chief ore of the metal tungsten.

Wolframite mainly occurs in quartz veins and pegmatites associated with granitic intrusive rock. Notable occurrences include the Nanling Range, China; southwestern states and Colorado in the USA; Russia; Korea; England; Bolivia; Portugal; Australia; Myanmar and the Malay Peninsula. Wolframite ore can be concentrated by gravity (spirals, cones, tables), sometimes in combination with magnetic separation.

Because Wolframite is a strong and quite dense material with a high melting temperature, it is an ideal material for electric filaments and armor-piercing ammunition, as well as hard tungsten carbide machine tools.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Wolfram Tungsten Ore Equipment for Tungsten Dressing or Wolframite Processing

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 16:24

- Written by xinyi

- Hits: 349

Wolfram is kind of essential mineral to get tungsten, and it is usually inlayed in granite and quartz together with cassiterite. Wolfram is weak magnetic with its density of 7.2-7.5g/cm3 and mohs hardness of 4-4.5.

The process of wolfram dressing is mainly gravity separation while sometime intensity magnetic separation can be involved. Wolfram tungsten ore is usually inlayed with coarse granules with big density and small hardness, so the specific separation or concentration of wolframite tungsten can be pre-selection, gravity separation after screening & classifying, intensity magnetic separation and treatment of fine tungsten mud.

The big density difference between wolfram and gangue makes gravity separation workable if the wolframite tungsten granules can be liberated or dissociated from the impurities. For the coarse tungsten or blocky tungsten separation, gravity separation can be used to get the coarse wolframite granules. Here the main wolfram dressing plant is jigging machine. The wolfram ore concentration machine can deal with ore of +80 meshes to 30mm. For some finer tungsten ore, shaking table or other equipment can be used to get the fine wolframite grains.

In the gravity separation of wolramite tungsten, the common processing plant can be jig separator and shaking table. Jigging machine is especially important to beneficiate wolfram tungsten of coarse and medium granules. The raw wolframite tungsten needs crushing and screening before jigging processing to gain high grade tungsten.

As kind of wolfram beneficiation machine, jig has been added to the circle of milling in order to reduce the pelitization of tungsten. The tungsten concentrate from jigging gravity concentration occupies a big part of the whole concentrate.

Shaking table is to separate wolfram of fine grains with its good enrichment ratio, great beneficiation efficiency. So the classifying of raw wolfram ore is necessary before separation.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Collimators Used in Radiation Therapy

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 16:20

- Written by wenjing

- Hits: 330

Tungsten collimators are used in linear accelerators used for radiotherapy treatments. Tungsten collimators help to shape the beam of radiation emerging from the machine, they can limit the maximum field size of a beam. The treatment head of a linear accelerator consists of both a primary and secondary collimator. The primary collimator is positioned after the electron beam has reached a vertical orientation. When using photons, it is placed after the beam has passed through the X-ray tungsten target. The secondary collimator is positioned after either a flattening filter (for photon therapy) or a scattering foil (for electron therapy). The secondary collimator consists of two jaws which can be moved to either enlarge or minimize the size of the treatment field.

New systems involving multileaf collimators (MLCs) are used to further shape a beam to localize treatment fields in radiotherapy. MLCs consist of approximately 50–120 leaves of heavy, metal tungsten collimator plates which slide into place to form the desired field shape.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Material Used in Collimator

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 16:13

- Written by wenjing

- Hits: 339

For industrial radiography using gamma radiation sources such as Iridium-192 or Cobalt-60, a collimator allows the radiographer to control the exposure of radiation to expose a film and create a radiographic "negative", a.k.a., a radiograph, to inspect materials for defects. A collimator in this instance is most commonly made of tungsten, and is rated according to how many half value layers tungsten material contains, i.e., how many times tungsten material reduces undesirable radiation by half. For instance, the thinnest walls on the sides of a 4 HVL tungsten collimator 0.52" thick will reduce the intensity of radiation passing through them by 88.5%. The shape of these collimators allows the radiographer to direct the radiation to the film and away from other workers.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Applications

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 16:03

- Written by xinyi

- Hits: 281

The main component of tungsten ore is tungsten.Tungsten is a dull silver-colored metal with the highest melting point of any pure metal.Also known as wolfram, from which the element takes its symbol, W, tungsten is more resistant to fracturing than diamond and is much harder than steel. It is the refractory metal's unique properties - its strength and ability to withstand high temperatures - that make it ideal for many commercial and industrial applications.

Applications:

Tungsten's primary application for over 100 years has been as the filament in incandescent light bulbs. Doped with small amounts of potassium-aluminum silicate, tungsten powder is sintered at high temperature to produce the wire filament that is in the center of light bulbs that light millions of homes around the world.

Due to tungsten's ability to keep its shape at high temperatures, tungsten filaments are now also used in a variety of household applications, including lamps, floodlights, heating elements in electrical furnaces, microwave ovens, x-ray tubes and cathode-ray tubes (CRTs) in computer monitors and television sets. The metal's tolerance to intense heat also makes it ideal for thermocouples and electrical contacts in electric arc furnaces and welding equipment. Applications that require a concentrated mass, or weight, such as counterweights, fishing sinkers and darts often use tungsten because of its density.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Production

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 15:56

- Written by xinyi

- Hits: 318

The main component of tungsten ore is tungsten.Tungsten is a dull silver-colored metal with the highest melting point of any pure metal.Also known as wolfram, from which the element takes its symbol, W, tungsten is more resistant to fracturing than diamond and is much harder than steel. It is the refractory metal's unique properties - its strength and ability to withstand high temperatures - that make it ideal for many commercial and industrial applications.

Production:

Tungsten is primarily extracted from two types of minerals, wolframite and scheelite. However, tungsten recycling also accounts for about 30% of the global supply. China is the world's largest producer of the metal, providing over 80% of the world supply.

Once tungsten ore has been processed and separated, the chemical form, ammonium paratungstate (APT), is produced. APT can be heated with hydrogen to form tungsten oxide or will react with carbon at temperatures above 1925°F (1050°C) to produce tungsten metal.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Mining Beneficiation Equipment, Tungsten Mineral Separator-Tungsten Washer

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 15:18

- Written by xinyi

- Hits: 318

As kind of common metal, tungsten is usually mixed in kinds of rocks with its low content, and it can be smelted after beneficiation. There is wolframites and Scheelite and at this moment, wolframites has been in dominating place to explore, occupying over 90%. For tungsten enrichment, hand separation, heavy medium separation, gravity separation, floatation separation, magnetic separation and electrical separation has been involved.

For wolframite tungsten ore, it has characteristics of low content, low grade, coarse granule inlay, big density, low hardness, easy argillization, and dark color. Its beneficiation is mainly gravity separation. The density difference between wolframites and impurities is big and gravity separation can be adopted. But the wolframites granules shall be liberated from the impurities. So the promary situation is to observe the crystal granule size of wolframites. If the wolframites inlay is corse or it is lumpy wolframites, coarse mineral jig separator can be used directly to gain high grade tungsten ore. The equipment involved cover crusher, rod mill, jig concentrator. If it is fine granules inlay or wolframites mud, shaking table or centrifugal separator can be used.

But for scheelite tungsten ore, it is usually mixed with sulfide, mainly molybdenite, and the beneficiation for scheelite is floatation separation. In alkaline medium, The PH is 9-10.5 by sodium carbonate and sodium hydroxide. The main inhibitor is sodium silicate, quebracho sap, tannin, and kinds phosphate while the main collectors are oleic acid, sodium oleate, tall oil, paraffin soap oxide. These collectors owns foaming nature, so there is no need of foaming agent here. In order to improve the floatation efficiency of scheelite ore, polyvalent metalsalts can be added to the solium silicate while pulp temprature shall be up to 70-90 celsius degree.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Types of Tungsten Ore-II

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 14:55

- Written by xinyi

- Hits: 330

There are 10 types of tungsten ore deposits in South China. Four types of fluid inclusions were found:

I.iquid-rich; II.Gas-rich; III.Liquid CO2-bearing; IV.Polyphase with daughter minerals.

Most common are type I inclusions. Type IV fluid inclusions only appeared in the porphyry and skarns. In skarns, type IV inclusions are evidently confined to the early stage, i.e., the simple silicate stage, but in the later scheelite mineralization stage, only types I and III inclusions occurred. Types II and III were found in the wolframite-quartz-sulfide veins, especially at the top of the veins.

Homogenization temperature and salinity were determined on the inclusions, and the pressure of formation was estimated from the inclusions. The homogenization temperatures of some of these types of tungsten ore deposits are as follows: porphyry, 386°C; greisen, 244–301°C; granite, 220°C; wolframite-sulfide-quartz veins, 240–310°C; wolframite-microcline-quartz veins, 267–325°C; stratabound, 219°C; and ferberite-quartz veins. 142°C. The salinity of fluid inclusions in the wolframite-sulfide-quartz veins type was only 5–10% equiv. NaCl. The pressures of formation, determined from the tomperature of homogenization, volume and density of phases in H2O-CO2 inclusions, from veins in three different wolframite-sulfide-quartz deposits, were 450, 550, and 750 atm., respectively. Most of the tungsten ore deposits were formed between 220°C and 390°C, with the porphyry highest and the ferberite-quartz veins type lowest. In the wolframite sulfide-quartz veins, four stages can be recognized: oxide-silicate; wolframitequartz-beryl; wolframite-quartz-sulfide; and carbonate. Throughout this sequence, the salinity and temperature decrease, e. g., from 293°C to 129°C.

It is concluded that these particular tungsten deposits were formed from a dilute water solution at moderate to high temperatures and at moderate pressures.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com