Tungsten Carbide Cutting Tool Edge Defects (B)

- Details

- Category: Tungsten Information

- Published on Sunday, 15 February 2015 09:09

the life of tungsten carbide cutting tools. Cutting edge surface usually produces the following defects: flash, micro-gap edge region, the residual stress and the blade surface area cobalt leaching.

3. Residual Stress

tungsten carbide cutting tools due to its texture, structure and manufacturing process and other factors, in the manufacturing and sharpening process, the remaining energy will be unevenly accumulate on the surface or inside of the tool, the performance of the residual stress and stress concentration. Residual stress and stress concentration exists, the tool in the cutting process is more sensitive to stress and thermal stress, prone to fatigue cracking and chipping, leading to decreased tool life or damage.

4. Cobalt leaching

In the process of grinding of tungsten carbide cutting tools, grinding fluid not only can reduce the grinding temperature, but also serve to improve the quality of grinding and grinding efficiency effects, and therefore widely used in the processing. China Tianjin University graduate student Zhang good strong analyze the mechanism of cemented tungsten carbide cobalt leaching, and the use of oleic acid, triethanolamine and borax as a cutting fluid additives. Experimental results show that this method can suppress the leaching of cobalt tungsten carbide elements, thereby increasing tool life and reduce the cutting fluid on the human body. Grinding tungsten carbide grinding fluid when it is possible to make use of tungsten carbide cobalt leaching. Cobalt cemented tungsten carbide as binder, it will greatly reduce the leaching tungsten carbide cutting resistance to mechanical impact and service life.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Edge Defects (A)

- Details

- Category: Tungsten Information

- Published on Sunday, 15 February 2015 09:07

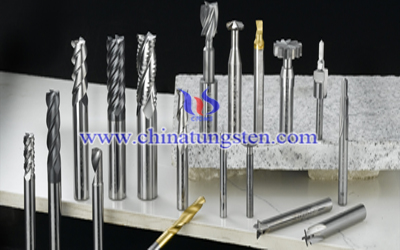

After grinding of tungsten carbide cutting tools, will be on the cutting edge defects, these defects can cause instability in the cutting process, the impact of the machined surface quality and reduce the life of tungsten carbide cutting tools. Cutting edge surface usually produces the following defects: flash, micro-gap edge region, the residual stress and the blade surface area cobalt leaching.

1. Burr

Tungsten carbide cutting tools on the cutting edge, there are many prominent thorn-like or burrs, called flash. Burr is small, the naked eye can not be observed, edges seem weak, but in reality is quite stubborn, using only grinding general, it is difficult to completely wear off. Cutting process, the burrs on the machined surface have swipe action, affecting the quality of the machined surface; moreover Burr easily collapse out or curl, curled edge will cause the cutting edge or chipping, thereby affecting the cutting tools.

2. Micro-gap

Tungsten carbide cutting tools after ordinary wheel or diamond grinding wheel, there are different degrees of micro-gap, these microscopic gaps are naked eye can not be observed, the microscopic gap width is generally 0.01 ~ 0.05mm, the width of the larger of 0.1mm or more. During cutting tool edge micro-gap easily extended, as the extension of the tool gap, increased wear, chipping and other phenomena will follow, accelerating tool wear and damage. If after grinding tool edge passivation, the tool becomes smooth edge, eliminating the exclusion of teeth, etc. jagged and crack defects.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

What Are The Characteristics of Tungsten Alloy Car Weight?

- Details

- Category: Tungsten Information

- Published on Sunday, 15 February 2015 08:51

Heavy alloy (tungsten) is a kind of material as the substrate of tungsten (W content of 85-99%), and added Ni, Cu, Co, Mo, Cr and other elements of the alloy. Press alloy composition characteristics and uses into W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, W-Ag and other major series, having a density of up to 16 .5-19.0g / cm3, and is the world known heavy alloy, it has a range of excellent features, heavy: General accounting for high 16.5-18.75g / cm3 ,, strength: tensile strength 700-1000Mpa, strong ability to absorb radiation: its capacity than lead 30-40%, thermal conductivity coefficient: 5 times mold steel; thermal expansion coefficient is small: only iron or 1 / 2-1 / 3, good conductive properties of steel; has good weldability and formability . Given the high proportion of these alloys have excellent features, it is widely used in the aerospace, aviation, military, oil drilling, electrical instrumentation, medical and other industries.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Dart Barrels

- Details

- Category: Tungsten Information

- Published on Friday, 13 February 2015 18:00

There are many different types of darts on the market from brass though to tungsten by far the most popular are tungsten nickel darts. Dart barrels is a dense heavy weight metal ideal for darts.

Tungsten has been used for the production of darts since the early 1970's because it is twice as dense (heavy) as brass and a dart made from tungsten will be half the size of a brass equivalent. This means it is easier for a player to achieve close grouping and score the maximum 180!

High percentage tungsten darts cost more than lower content dart barrels, the main reason for this is down to the machining of the billet. High percentage tungsten darts take longer to make and wear the cutting tools faster. The speed of the cutters has to be turned down to a slower speed so to prolong the life of the cutting tool therefore this increases the production cost of making the finished dart barrels.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparation of Ammonium Paratungstate with Coarse Grain By Evaporating Crystallization

- Details

- Category: Tungsten Information

- Published on Friday, 13 February 2015 16:53

In the recent years , many users at home and abroad have strict quality requirement not only in chemical composition but also in physical properties . Including particle-size and distribution (or apparent density ), crystal shape and so on .therefore, it is important to investigate the preparation of APT with coarse grain has been investigated systematically. A new technology for the crystallization of ammonium paratungstate with coarse grain has been studied. The factors influencing the physic-chemical properties of ammonium paratungstate crystal, such as temperature ,concentration in the process, and the addition of seed crystal and agitation with air is also in favor of the system. Ammonium paratungstate crystal with particle size of 36-42um and apparent density of 2.0-2.2g/cn-3 were obtained by controlling suitable technological parameters.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Shape and Particle Size Distribution Effect on APT Crystal

- Details

- Category: Tungsten Information

- Published on Friday, 13 February 2015 16:50

The physical properties of APT sample prepared in our research were measured in comparison with some commercial APT samples produced by traditional APT samples produced by traditional method. It has been observed that the APT sample using our method has a shape nearly regular cubic crystal and even particle size, while the commercial samples have relatively bad regularity, besides some cubic crystals, there are some topical tabular crystals and some rod-like crystals, and the particle size distribution is uneven.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Agitation Effect on APT Crystal

- Details

- Category: Tungsten Information

- Published on Friday, 13 February 2015 16:43

Agitation can promote the relative movement between solid and liquid, and make the concentration and the temperature in the solution even. Moreover is also favorable for crystalline grains growing evenly in all directions, so coarse grains with large apparent density can been obtained. The crystalline grains may be fined when the speed of agitation is very great. For this reason, experiments of two different kinds of agitation, mechanical agitation and air agitation, has been carried out. The experiments indicate that the apparent density of APT crystals obtained by air agitation is usually coarser than that obtained by mechanical agitation. This may be because the mechanical action upon the crystal caused by air flow is weaker than that caused by mechanical agitation.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Seed Crystal Effect on APT Crystal

- Details

- Category: Tungsten Information

- Published on Friday, 13 February 2015 16:40

As well-known, the addition of seed crystal, especially active seed crystal, is usually favorable for restraining the formation of new nuclei and promoting the growth of crystalline grains during crystallization. A series of experiments have been made using active APT crystal prepared under special conditions as seeds. It can be seen that with the same experimental conditions, the apparent density of APT crystal made by seed crystal is coarser than that produced without seed crystal.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Concentration of WO3 Aqueous Effect on APT Crystal

- Details

- Category: Tungsten Information

- Published on Friday, 13 February 2015 16:37

The concentration of WO3 directly influences the over –saturation of the solution which has an important effect upon both the speed of nucleation and crystal growth. It is show that the higher the concentration of WO3, the larger the over-saturation of the solution, the smaller the APT crystal obtained. We have observed with microscope that the crystal obtained of WO3 has three shapes agglomerates of small cubic particles; needle crystals and tabular –like. This is because in the high over-saturation (NH4)2WO3 aqueous, the supply of APT solute for APT crystalline grains growing is uneven, so that on the active centers of the crystal-edges and the crystal pinpoints, there are more chances to receive APT solute for growing rapidly. Therefore, the needle crystals and tabular-like crystals are formed easily.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Temperature Effect on APT Crystal

- Details

- Category: Tungsten Information

- Published on Friday, 13 February 2015 16:29

Puring the crystallization of APT crystals, temperature has double effects on APT crystals. On the one hand, rising temperature will increase the growth rate of the crystalline grains, and help to make coarse grain APT. On the other hand, higher temperature will lead to rapid volatilization of NH3 and cause the over- saturation of the solution ,and a large amount of nuclei were formed. In this case coarse grain crystals can not be obtained. Therefore , it is necessary to find out which effect on APT crystals plays a dominant role in the crystallization process of APT.

Solution with different initial concentrations of (NH4)2WO4 were used for studying the influence of temperature on the apparent density and FSSS size. The results show the apparent density and FSSS size increase obviously with the raising of temperature, and APT crystals with an density more than 1.8g/m-3 and a FSSS size more than 32 um are obtained at temperature higher than 90℃. This is because at higher temperature, the activity of the active center on the surface of crystalline grains increases, and the rate of nucleating is slower than that of crystal growing. It was clearly observed through a microscope that the APT crystals made at higher temperature are coarser than that obtained at lower temperature.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com