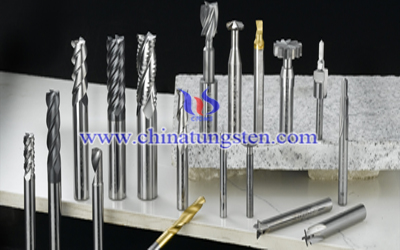

Tungsten Carbide Cutting Tools Oxidation Wear

- Details

- Category: Tungsten Information

- Published on Friday, 27 February 2015 09:08

A refractory metal tungsten carbide cutting tools hard metal compound and a binder made by powder metallurgy method, its hardness (HRA) is 89 to 94, much higher than the high-speed steel; at 540 ℃ hardness (HRA) 82 to 87, and the hardness of high-speed steel normal temperature (HRA83 ~ 86) fairly, but also has good chemical stability, heat resistance advantages. tools materials currently used for a lot of variety though, the new tools materials are also emerging, but still very popular tungsten carbide cutting tools material kind.

When cutting titanium, tungsten carbide cutting tools cutting when the temperature reaches 700 ~ 800 ℃, tungsten carbide materials WC, TiC, and Co compounds and plays the role of oxygen in the air, forming a lower hardness and strength oxide film. As air enters the cutting area is not easy, it is easy to form an oxide film on the flank position after tungsten carbide cutting tools. When cutting the workpiece surface by the oxide, chilled layer and hard impurity continuous friction points on the oxide film, resulting in oxidation of flank wear, also called boundary wear. When a large amount of wear and tear, will form oxidation wear grooves. After tungsten carbide cutting tools oxidation wear mainly as tools and vice flank flank have emerged oxidation wear phenomenon. And this phenomenon is more pronounced in high-speed cutting.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Blanks Preparation Process(a)

- Details

- Category: Tungsten Information

- Published on Friday, 27 February 2015 08:44

Qualified tungsten blanks is one of the key timber production, a good system to choose a qualified first blank tungsten powder. Feature powder (average particle size, particle size distribution, chemical composition), mixing, forming and sintering process on the blank composition, density and microstructure have a direct impact, and strongly influences the processing and performance. Does not sag tungsten added silicon, aluminum, potassium is tungsten trioxide or "Blue W" (for a variety of low-cost tungsten oxide mixture) in the form of oxides added, the mixture containing hydrofluoric acid solution used washed to remove impurities in the powder.

Production of silk and small blank sheet more in the press forming, may also isostatic press forming. Powder compact size is generally 12 × 12 × 400 mm, there is also a larger-sized round bar, square bar or rectangular bar. First obtaining 1200 ℃ powder compact in a hydrogen atmosphere for 1 hour so as to have prefired certain strength and electrical conductivity, and then perform a power on self resistance sintering. Self-powered resistance sintering commonly known as "vertical melt" is a method developed tungsten processing. The principle is the current directly through the sintered compact, due to the resistance of the blank itself, Joule heat is generated, with this heat the billet sintering, the sintering current is typically 90% of the fusion current. The resulting self-resistance sintered blank strips (also known as a sintered article).

Processed into a general standard vertical wire melting section shall control the number of grains per square millimeter of about 10,000 to 20,000, a density of 17.8 ~ 18.6 g / cm 3. For pipe, sheet, or other large-sized products, often using isostatic pressing (pressure at 2500 kg / mm 2 or more) formed and sintered at 2300 ~ 2700 ℃ high temperature in a vacuum or hydrogen protection.

Swaging the blank is produced and the fine tungsten wire rods commonly used plastic working method, different sizes of rods in a hydrogen atmosphere is heated to 1400 ~ 1600 ℃, be swaged on a different model of the swaging machine. Start track deformation of the times is not too large, then be appropriate to increase the amount of deformation. Swaging deformation between the workpiece and the die graphite lubrication process. Tungsten rod density after processing up to 18.8 ~ 19.2 g / cm 3. Because forging billet into a round billet, deformation of each part is different, so the organization is uneven, you should recrystallization annealing.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Carburization of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 14:16

Tungsten carbide powder is conventionally produced by carburization of tungsten powder by carbon black in a solid–solid reaction. Carburization of ammonium paratungstate by methane to yield tungsten carbide at low temperature in short times. The carbide powder is fine grained and has specific surface area around 35m2/g. This makes the powder interesting for catalysis and fine grained hard metals. The influence of reaction parameters such as temperature, gas flow, composition of the reaction gas and powder charge are investigated by means of gas chromatography and XRD with Rietveld refining. The overall reaction time is the sum of reduction and carburization times of the sequential reactions. Some parameters, like gas composition affects only the carburization rate, other parameters, such as gas flow affects both reactions.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparation High Purity APT

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 14:13

Ammonium paratungstate is produced separating tungsten from its ore. Once the ammonium paratungstate is prepared, it is heated to its decomposition temperature, 600°C. Left over is WO3, tungsten oxide. From there, the oxide is heated in an atmosphere of hydroge, reducing the tungsten to elemental powder, leaving behind water vapor. From there, the tungsten powder can be fused into any number of things, from wire to bars to other shapes.

I.E. mechanical activating caustic decomposition and removing molybdenum from tungstate soluton by ion exchange method are used in this technological process for treating low grade tungsten concentrate with a low concent of WO3 and a high content of calcium and impurities to produce APT of high purity. The combination of whole technological process is reasonable and has the advantages of shorter high recovery of tungsten and high purity of product.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Microwave Decomposition of Solid Crystalline APT

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 14:06

Ammonium paratungstate(APT) is a white crystalline salt of ammonium and tungsten, with the chemical formula (NH4)10(H2W12O42)·4H2O.

Microwave decomposition of solid crystalline ammonium paratungstate (APT) and ammonium metatungstate (AMT) was investigated. It was observed that APT and AMT interact with 2.45-GHz microwave radiation. Samples of ammonium paratungstate (20-50 g) were successfully converted into WO3-x (0 ≤ x ≤ 0.2). A wide variety of morphological parameters were found. The interaction of AMT with the 2.45-GHz microwave radiation resulted in the partial loss of crystalline water and the partial dissolution of the sample in the released water.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Blue Tungsten Oxide Preparation out of Ammonium Paratungstate Self-Reduction

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 14:02

Hydrogen produced in the cracking process of heated Ammonium paratungstate is used for the self-reduction of the cracked products. The impacts on blue tungsten oxide's properties by the major reduction parameters, including temperature and rotary kiln speed without ammonia or hydrogen. The application of this technology to environmental protection, energy conservation and production safety are focused.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Morphology and Distribution Effect on Tungsten Powder Particle Shape

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 13:57

The strength of tungsten powder compacts mainly results from particles of irregular surface for particle shape is one of the most important factors affecting strength of tungsten powder compacts. Ammonium paratungstate has great influence on the tungsten powder particle shape. The compact strength varies greatly under the same process and raw materials with different properties while producing high compact performance tungsten powder using ammonium paratungstate one step reduction. The features of ammonium paratungstate for producing high compact performance tungsten powder are summarized by the experiments.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Calcination Temperature's Impact on the Determination Result of Sulfur in APT

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 13:52

Sulfur determination method in tungsten trioxide by high-frequency infrared carbon-sulfur analyzer. The effect of APT's calcination temperature on the sulfur content determination under the optimal instrument working conditions is studied. Experiments show the optimal calcination temperature of APT samples is 425℃. At the optimal temperature, water and NH3 in APT sample can be removed efficiently. In addition, the sulfur content in the sample can keep intact without decomposition and volatilization. The experimental results can truly reflect the determination of sulfur in APT sample. The sulfur determination scope ranges from 0.0005% to 0.3000%, and the recovery of standard addition is 98.6%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate in the Method of the Analysis of Impurities

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 13:46

The spectrophotometric determination of impurities in the ammonium paratungstate, mainly determined by the reaction temperature, reaction time, NaOH concentration and stirring speed on the active ingredients wolframite tungsten leaching. Also investigated the properties of the resin in the ion exchange process, the exchange of the solution before concentration and flow rate, desorbent concentration, flow rate and temperature and other factors on the impurity removal rate during crystallization temperature paratungstate crystals.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Adhesive Wear

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 09:58

Bonding refers tungsten carbide cutting tools and workpiece material when exposed to the interatomic distance generated combined phenomenon. TC4 titanium alloy in high-speed cutting, the cutting temperature is high, the contact pressure, and the presence of microscopic surface roughness knife, resulting in reduced tungsten carbide hardness and adhesion between the workpiece and the tungsten carbide cutting tools and the workpiece material elemental affinity. When the bond strength high enough parts, parts outside of the local bond being cut. Shear occurs when the inner tool, part of the tools will be taken away chips, small-scale occurrence called adhesive wear, a large scale called chipping.

Small elastic modulus tungsten carbide cutting tools materials, the surface prone to rebound, so the process of cutting a large radial force, the actual contact area between the tools and the workpiece increases, the chip after the tools moves along the flank, the destruction of the hard after the alloy tools flank surface oxide layer, leading to flank wear after bonding tool. With the cutting progresses, eventually leading off the adhesive flank wear. At present, the international community generally after flank wear as a measure of the main criteria for tungsten carbide cutting tools life, severe flank wear will reduce the machined surface quality and dimensional accuracy. So after controlling for flank wear is an important way to improve the durability of tungsten carbide cutting tools.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com