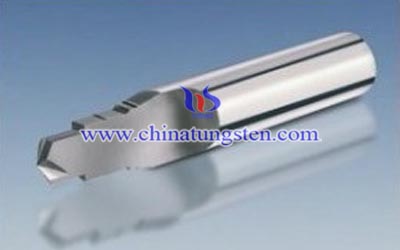

Tungsten Carbide Cutting Tools Wear Mechanism

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 09:56

Wear is accompanied by a phenomenon generated by the friction, the two surfaces in contact with each other, in the process of mutual friction, decreases the volume of the phenomenon itself. Tungsten carbide cutting tools wear patterns and wear mechanisms associated with many factors, such as friction of chemical, physical and mechanical properties. The main wear mechanism of cemented tungsten carbide cutting tools wear are: abrasive wear, the phase transition wear, adhesive wear, diffusion wear, oxidation and wear.

Tungsten carbide cutting tools and the workpiece in the process of friction and wear phenomena are not independent of each other, but a variety of wear mechanisms result of the role. tools wear into normal wear and abnormal wear. Abnormal wear of the tools is mainly due to the toughness or hardness is too low, the structure or geometry of the tools is unreasonable; the cutting edge caused by excessive force chipping; Cutting selected unreasonable, resulting in cutting force is too big or too warm cutting high; there may be other reasons improper operation by the cutting edge chipping lead to sudden shocks. Normal wear of tungsten carbide cutting tools means the amount of wear of the tools with cutting time increases with evenly. tools normal wear due to a mechanical wear, abrasive wear, adhesive wear, abrasion diffusion, phase transition wear, oxidation wear, thermal wear, a thermoplastic deformation.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Machining of Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 09:14

Tungsten is hard, so it is sensitive to notch, which is difficult for cutting and requiring the use of carbide cutting tools. To prevent cutting cracks, it is often heated the workpiece to plastic - brittle transition temperature than cutting, and to strictly control the cutting operation program.

Tungsten grinding requires a specific type of light grinding wheel, and needs to be cooled, otherwise it will crack. Thickness of 0.2 mm or more in front of tungsten sheet punching and shearing to be pre-heated over a certain thickness of the plate, not cut, often need to use the wheel cutting.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Nuclear Medical Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Monday, 16 February 2015 16:19

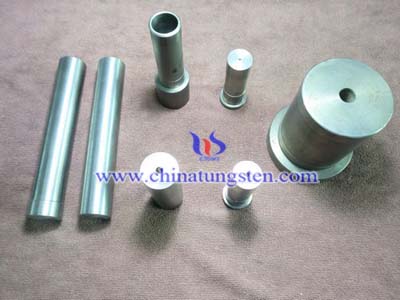

Tungsten is a ideal material for shielding against χ rays and gamma radiation .The very high density of tungsten shielding(more than 60% denser than lead) allows a reduction in the physical size of shielding components, without compromising their rigidity or the effectiveness of the shielding characteristics.

Whether you need to protect sensitive electronic equipment or delicate human tissue, the energy-absorbing properties of T&D’s tungsten alloys make them exceptional choices for radiation shielding applications, in both medical and industrial settings.

Compared to traditional radiation shielding materials, tungsten alloys provide excellent value. A high-density alloy can provide the same energy absorption as lead using 1/3 less material! Unlike lead, you’ll also reduce administration costs by eliminating the need to obtain special licensing—it’s not required.

Clients all across the globe are taking advantage of tungsten alloy’s reliable radiation shielding properties. If you need to protect yourself, your patients or your equipment from the harmful effects of excess radiation, come to us!

Our products are available as finished machined parts or as short rod, round bar, and rectangular blocks.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797 Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Heavy Alloy PET Pig Syringe Shield

- Details

- Category: Tungsten Information

- Published on Monday, 16 February 2015 16:16

Tungsten heavy alloy PET pig dyringe dhield/radiation shielding is a suitable raw material for radiation protection, as its combination of radiographic density (more than 60% denser than lead), machinability, good corrosion resistance, high radiation absorption (superior to lead), simplified life cycle, non-toxic and high strength. It can provide the same degree of protection as lead whilst significantly reducing the overall volume and thickness of shields and containers. Besides, compared with lead or depleted uranium in the past, wolfram alloy is more acceptable in this case, for they are non-toxic.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797 Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Darts Categories

- Details

- Category: Tungsten Information

- Published on Monday, 16 February 2015 16:12

There are 4 general categories of tungsten darts. Nowadays, the tungsten dart is popular among top players. As it was known, was long-lasting, did not need soaking and was more resistant to damage by darts than poplar darts.

1,50% to 70% Tungsten- $15 to $50 (commonly sold at discount stores)

2,80% Tungsten - $25-$75 (popular with new league players)

3, 90% Tungsten- $50-$200 (high density, will hold up well, feel better to throw.)

4,95% to 98% Tungsten - $100 - $200 (high density, thinner, resist wear, feel better to throw. However,slightly more likely to break.)

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Darts

- Details

- Category: Tungsten Information

- Published on Monday, 16 February 2015 16:10

The billets that tungsten darts are made from consist of a variety of metals, including tungsten. To manufacture the blanks for machining tungsten darts, tungsten powder and other metals are blended and bonded by heat and pressure, resulting in a "sintered" material that we refer to as Nickel-Tungsten (or Copper-Tungsten, etc.) Common materials include tungsten, nickel, copper, and iron.

Discount outlets often sell low-density tungsten darts without specifying the percentage of tungsten content, but just say "Tungsten Darts". Such darts are often cheap Chinese imports of poor quality. Look for the percentage of tungsten on the packaging, a higher number means that the dart is more dense, and generally better quality.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Dart Price Will be Raise

- Details

- Category: Tungsten Information

- Published on Monday, 16 February 2015 16:08

Tungsten dart prices have gone up in recent years, raising the tungsten dartprice of quality darts sets. However, in order to offer "bargain" prices, many sporting good stores & discount outlets now sell cheap "Tungsten Darts" that actually contain only a tiny trace of tungsten in them.

Many of these cheap sets are about the same density as brass (or less), but cost quite a bit more. Always look for the percentage of tungsten on the package, and buy from a reliable vendor.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Edge Smoothness and Integrity

- Details

- Category: Tungsten Information

- Published on Monday, 16 February 2015 10:15

tungsten carbide cutting tool edge smoothness and integrity is an important factor to evaluate the quality of tungsten carbide cutting tool in the production process, therefore needs to be reasonable control.

1. Tungsten Carbide Cutting Tool Edge Smoothness

More smooth cutting edge passivation of the better, that relatively small number of chipping. Originally present on the cutting edge chipping, smaller width needed to completely remove; chipping width larger, the need to have to become smooth chipping nearby. When the machine speed is too high or nylon abrasive particles are too large, it will lead to increased kinetic energy of particles, collisions between particles and the cutting edge of severe, can cause chipping, there is likely to make the original width larger chipping . In order to ensure the smoothness of the cutting edge, the use of abrasive brushes mesh number the better, while the machine speed is not too high.

2. Tungsten Carbide Cutting Tool Edge Smoothness Integrity

Integrity blade means and whether there is chipping off the block and other defects on the cutting edge. Vibration process, if the collision with the cutting edge of the abrasive is too severe, can lead to edge chipping or cutting off the block, which will affect the surface quality of the blade. You can adopt the following measures: reducing motor speed and abrasive particle size increases.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Edge Uniformity

- Details

- Category: Tungsten Information

- Published on Monday, 16 February 2015 10:13

Uniformity refers to consistency throughout the tungsten carbide cutting tool edge on the cutting edge shape. Tungsten carbide cutting tool clamping way affect the uniformity of the edge of the arc. Freestyle abrasive blade in the container together with the random motion, but also a roll, so the friction and wear throughout the blade edge is consistent, then even better in all directions. For fixed type, the speed of the entire abrasive is not the same, the speed of the bottom is large, the kinetic energy of the bottom of the larger abrasive particles, the abrasive particles collide with the bottom of the cutting edge even more, while the upper part is small, the , under the same conditions, the friction and wear at the bottom of the larger, the larger edge radius cutting edge; the same time, the blade is fixed, the number of collisions can affect the local abrasive particles and the cutting edge, leading to partial edge radius is too small.

In general, the material at the tip of tungsten carbide cutting cutting tool to remove than larger, resulting in a blunt tip at a larger radius. The main reason is the lower part of the nose strength, heat resistance and poor wear faster. To ensure uniformity, may be added a small amount of coolant used in the passivation process, and the larger the abrasive brush abrasive grit brush.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Introduction of Tungsten Alloy Transport Counterweight

- Details

- Category: Tungsten Information

- Published on Monday, 16 February 2015 09:57

Due to high density tungsten alloy, good tensile strength and ease of processing and pollution and other characteristics, and therefore became the most popular means of transport as a counterweight material.

★ Counterweight for yachts, boats, submarines, or other types of boats

★ Car and other models crankshaft counterweight

The right balance to make the car's performance to be the greatest play. Our car chassis weight member is twice the density of steel, but only half the weight of lead.

Tungsten alloy counterweight racing will:

• Keep your lower center of gravity;

• Adjust the balance of front and rear;

• After machining can be just right for racing chassis;

• threaded holes at both ends to make the operation more flexible;

• Standard counterweight block size is 2 5/8 "x 3 5/8" x 6 ", weighs 35 pounds.

• also produce other sizes of weights.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com