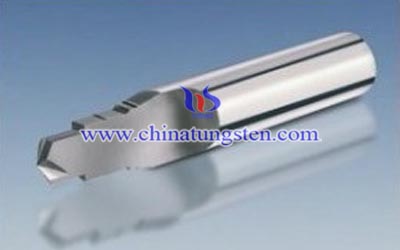

Tungsten Carbide Cutting Tools Wear Mechanism

- Details

- Category: Tungsten Information

- Published on Thursday, 26 February 2015 09:56

Wear is accompanied by a phenomenon generated by the friction, the two surfaces in contact with each other, in the process of mutual friction, decreases the volume of the phenomenon itself. Tungsten carbide cutting tools wear patterns and wear mechanisms associated with many factors, such as friction of chemical, physical and mechanical properties. The main wear mechanism of cemented tungsten carbide cutting tools wear are: abrasive wear, the phase transition wear, adhesive wear, diffusion wear, oxidation and wear.

Tungsten carbide cutting tools and the workpiece in the process of friction and wear phenomena are not independent of each other, but a variety of wear mechanisms result of the role. tools wear into normal wear and abnormal wear. Abnormal wear of the tools is mainly due to the toughness or hardness is too low, the structure or geometry of the tools is unreasonable; the cutting edge caused by excessive force chipping; Cutting selected unreasonable, resulting in cutting force is too big or too warm cutting high; there may be other reasons improper operation by the cutting edge chipping lead to sudden shocks. Normal wear of tungsten carbide cutting tools means the amount of wear of the tools with cutting time increases with evenly. tools normal wear due to a mechanical wear, abrasive wear, adhesive wear, abrasion diffusion, phase transition wear, oxidation wear, thermal wear, a thermoplastic deformation.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com