Tungsten Alloy Collimator Applied for Nuclear Medicine

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 16:16

Tungsten alloy collimator provides the perfect solution for radiation shielding and collimation in nuclear medicine. Because tungsten alloy has excellent radiation attenuation properties, such a collimator has a reduced volume than traditional lead collimator, while it can still effectively shield harmful X-ray and gamma radiation.

SPECT Tungsten Alloy Multipinhole Collimator

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 16:15

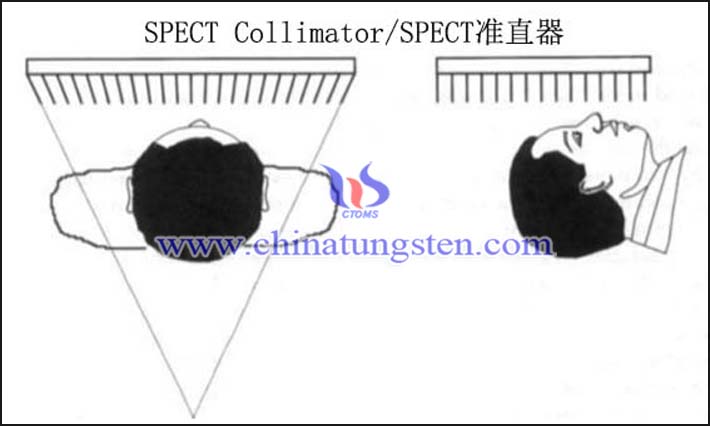

SPECT tungsten alloy multipinhole collimator is tungsten alloy collimator applied for nuclear medicine tomographic imaging technique using gamma rays. And sometimes SPECT tungsten alloy multipinhole collimator is an integrated SPECT collimator for laboratory rats. Tungsten alloy multi-pinhole collimator is an indispensable four-dimensional accurate quantitative imaging and animal experiment auxiliary system.

Tungsten Alloy Collimator Applied for SPECT

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 16:13

Tungsten alloy collimator is a device used to restrict the photon acceptance angle to provide positional information for detected photons. SPECT tungsten alloy collimator is a thick sheet of tungsten alloy of high atomic number, pierced by an array of holes.

Tungsten Alloy Collimator Applied for Gamma Camera

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 16:10

Tungsten alloy collimator is an important part of a gamma camera (γ camera). And it plays the role of radiation guidance (collimation) and radiation protection (reducing the patient's exposure to gamma rays) on the core component of the gamma camera.

Ion Fan Tungsten Needle

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 11:50

Ion fan tungsten needle refers to the tungsten needle used for an ion fan. Wherein, the ion fan has excellent anti-static performance, can prevent static electricity pollution, and is small, light, and easy to install. It is an ideal equipment for personal static protection areas such as electronic production lines and maintenance stations.

Argon Arc Welding Tungsten Needle

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 11:49

Argon arc welding tungsten needle is more often known as argon arc welding tungsten electrode. And such a needle may be a thoriated tungsten electrode, a cerium tungsten electrode, or a lanthanated tungsten electrode, etc.

TIG Welding Lanthanated Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 11:47

TIG welding lanthanated tungsten electrode has no radioactive hazard, and has high durability current, minimum burnout rate, excellent welding performance, and the closest electrical conductivity to 2% thoriated tungsten electrode. Therefore, it is mainly used to replace the radioactively contaminated thoriated tungsten electrode.

TIG Welding Thoriated Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 11:46

TIG welding thoriated tungsten electrode has excellent comprehensive performance, especially can withstand overload current. It is easy to start the arc and not easy to deform. And it has characteristics of long service life, anti-oxidation, continuous arc during welding, stable arc, and no scattered arc.

How to Prepare Nano-porous Yellow Tungsten Oxide Photocatalyst?

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2020 16:37

How to prepare nano-porous yellow tungsten oxide photocatalyst? Or how to prepare nano-porous WO3 photocatalyst? The researchers proposed a method to prepare porous WO3 with characteristics of good chemical stability and easy separation. And the process will not cause secondary pollution to the environment.

An Ideal Photocatalytic Material: Yellow Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2020 16:35

It is reported that porous yellow tungsten oxide, or porous tungsten trioxide (WO3), is an ideal photocatalytic material as the pore structure has a strong ability to degrade dyes. Therefore, tungsten trioxide with pore structure can be used to photodegrade dyes in industrial wastewater.

sales@chinatungsten.com

sales@chinatungsten.com