Tungsten Carbide Slitting Circular Blade

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2020 11:19

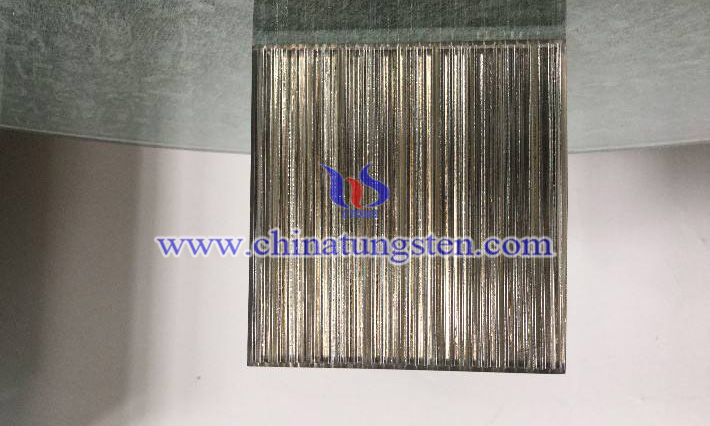

Tungsten carbide slitting circular blade has a long working cycle as it has characteristics of high hardness, high strength, sharp cutting edge, good wear resistance, acid resistance, alkali resistance, corrosion resistance, oxidation resistance, rust resistance and high temperature resistance. The service life of such a tungsten carbide blade is more than 10 times the life of high speed steel blade. And the service life of tungsten carbide slitting circular blade after coating is dozens or even hundreds of times that of high speed steel slitting circular blade.

A New Process For Recovering Ammonium Tungstate From APT Crystallization Mother Liquor

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2020 17:54

The researchers proposed a new process for recovering ammonium tungstate from APT crystallization mother liquor. This process improved the existing problems of high consumption of auxiliary materials, high production cost and large energy consumption in the prior art.

A Preparation Method of Ammonium Paratungstate Using Tungsten-contained Soft Waste Material

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2020 17:52

The researchers proposed a preparation method of ammonium paratungstate (APT) using tungsten-contained soft waste material. And the obtained APT can be directly used in the production of tungsten alloys or be applied as additives for chemical products.

Preparation of Ammonium Paratungstate Using Tungsten-contained Waste Material

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2020 17:51

Researchers have proposed a method for producing ammonium paratungstate using tungsten-contained waste material, which has the advantages of short production process. Evaporated and crystallized waste ammonia gas and wastewater can be recycled and reused. And it significantly reduces emissions of waste gas and wastewater. Also, it improves the tungsten recovery rate.

Tungsten Carbide Glass Cutter Applied for Cutting Plate Glass

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2020 16:05

Tungsten carbide glass cutter is welcomed for cutting plate glass. And it is the tungsten carbide cutting wheel that plays a role of scoring a line on the glass, and then split it through mechanical stress along the line. The advantage of this method is that the processing method is simple, the glass can be effectively broken, and the cost is relatively low.

Tungsten Carbide Glass Cutter Applied for Cutting Wired Glass

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2020 16:04

Tungsten carbide glass cutter for cutting wired glass adopts tungsten carbide as the material of its cutting wheel and non-slip pen design, which has characteristics of sharp cutting, fast speed, high precision, wear resistance, corrosion resistance, high hardness and long service life. Using tungsten carbide glass cutter, it is easy to get smooth, flat and beautiful cut surface. Also, it is non-slip and is safer to use.

Tungsten Carbide Glass Cutter Applied for Glass Cutting

- Details

- Category: Tungsten Information

- Published on Thursday, 25 June 2020 16:02

Tungsten carbide glass cutter is a tool with a small tungsten carbide cutting wheel, which is widely applied for glass cutting as it has advantages of high hardness, wear resistance, heat resistance, corrosion resistance, good strength and toughness. Especially, high hardness and high abrasion resistance of such a glass cutter remains basically unchanged even at a temperature of 500 °C. Also, it still has a high hardness at 1000 °C.

How to Improve Photocatalytic Performance of Yellow Tungsten Oxide?

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 16:58

How to improve photocatalytic performance of yellow tungsten oxide? The researchers proposed a method to improve the photocatalytic performance of yellow tungsten oxide (tungsten trioxide/ WO3). Through this method, WO3 photocatalyst showed higher photocatalytic activity than the single crystal phase WO3in the photocatalytic degradation of water to produce hydrogen and degradation of pollutants.

A Promising Semiconductor Photocatalytic Material: Yellow Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 16:57

It is reported that yellow tungsten oxide, is not only a typical n-type semiconductor material, but a promising semiconductor photocatalytic material. Yellow tungsten oxide, also known as tungsten trioxide or WO3, is considered to be a semiconductor photocatalytic material with great development potential due to its high solar energy utilization rate, good visible light response and strong photocorrosion resistance, and has been widely used in hydrogen production from photolysis water and catalytic degradation of organic pollutants.

Yellow Tungsten Oxide Applied for Organic Waste Gas Purification

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 June 2020 16:55

Yellow tungsten oxide can be applied for organic waste gas purification in heavy polluting industries. There are two appropriate measures for treatment of organic waste gas in heavily polluted industries: recovery method - separation and recovery through physical methods; elimination method - reduction of toxic waste gas through chemical and biological reactions. Wherein, using yellow tungsten oxide to treat organic waste gas belongs to the photocatalytic oxidation method in elimination method.

sales@chinatungsten.com

sales@chinatungsten.com