Cs-137 Tungsten Alloy Shield

- Details

- Category: Tungsten Information

- Published on Sunday, 05 July 2020 16:45

Cs-137 tungsten alloy shield refers to tungsten alloy shield used to shield the cesium-137 radioisotope in medical applications. And it can also be used in agriculture and nuclear power plants.

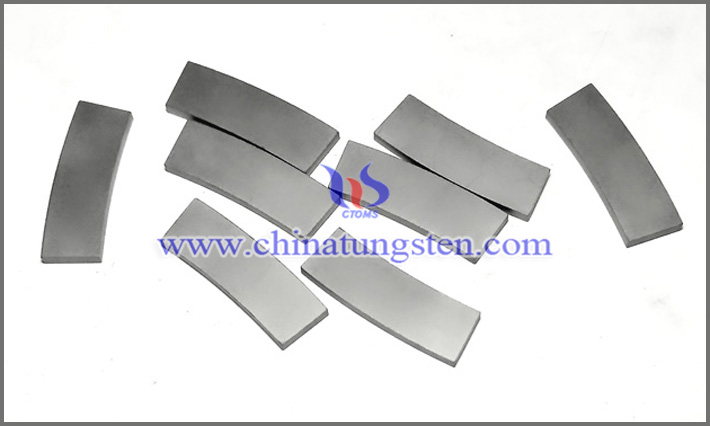

A New Lead-free Radiation Shielding Material: Tungsten Alloy Shielding Material

- Details

- Category: Tungsten Information

- Published on Sunday, 05 July 2020 16:44

Tungsten alloy shielding material is considered to be a new lead-free radiation shielding material with broad application prospects. It is environment-friendly and non-toxic, and has characteristics of high hardness, good corrosion resistance, excellent radiation absorption performance, strong mechanical properties, and high compressive strength.

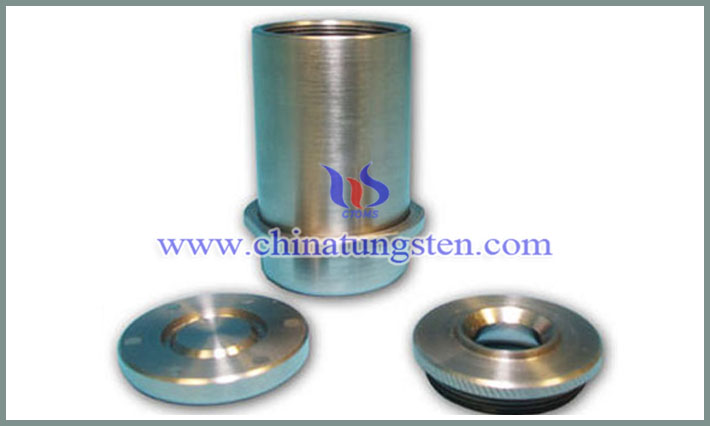

Tungsten Alloy Vial Shield With Magnetic Cap

- Details

- Category: Tungsten Information

- Published on Sunday, 05 July 2020 13:41

Tungsten alloy vial shield is designed for vials containing liquid radioisotopes. Such a vial shield of tungsten based alloy has higher density than traditional lead vial shield so that it has better radiation absorption performance. It features a removable screw top with a magnetic cap. Speed of handling reduces exposure. Another design feature is the holding ring which fits comfortably in the hand or into a dispensing stand. The magnetic cap holds the lid in place even when inverted on the stand. Machined with 0.2" thick tungsten, the vial shield accommodates most 10 ml vials.

Cobalt-60 Tungsten Alloy Shield

- Details

- Category: Tungsten Information

- Published on Sunday, 05 July 2020 13:39

Cobalt-60 tungsten alloy shield refers to tungsten alloy shield used on the cobalt-60 therapy apparatus, or the container used to store and transport cobalt-60, and so on. Cobalt-60 therapy apparatus is a large medical device that performs radiotherapy on tumors. Cobalt-60 is a kind of radiation with strong radioactivity (strong gamma source), which can be used to treat cancer, but it can cause hair loss, can seriously damage the cells and tissues in the human blood, cause the decrease of white blood cells, and cause blood system diseases, such as aplastic anemia can severely cause leukemia and even death.

Tungsten Alloy Gamma Ray Shielding Material

- Details

- Category: Tungsten Information

- Published on Sunday, 05 July 2020 13:38

Tungsten alloy gamma ray shielding material overcomes the shortcomings of traditional lead shielding material, and is more often used in medical fields. More specifically, tungsten alloy gamma ray shielding material does not produce secondary bremsstrahlung, and has a high hardness, which can maintain a certain shape very well when it is made into large containers and large equipment. But if lead is used as the gamma ray shielding material for manufacturing large containers and large equipment, in order to avoid the collapse of the containers and equipment due to their own weight, it is necessary to use steel as the structural framework.

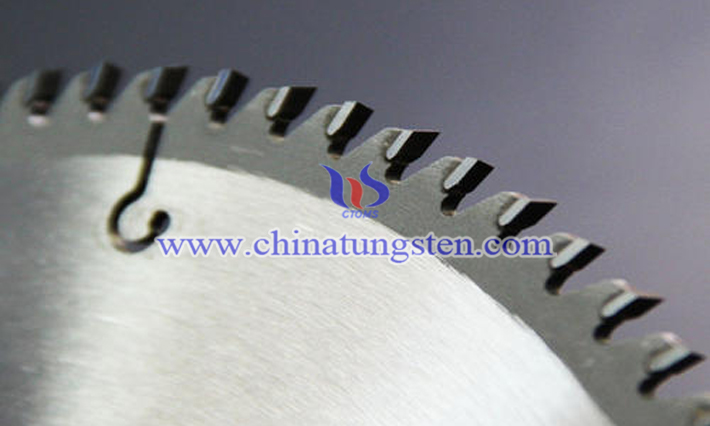

How to Choose Sawtooth Angle of Tungsten Carbide Saw Blade?

- Details

- Category: Tungsten Information

- Published on Sunday, 05 July 2020 13:10

How to choose sawtooth angle of tungsten carbide saw blade? The angle parameters of sawtooth of saw blade are more complicated. It is the key of cutting quality of workpiece by correctly selecting the angle parameter of saw blade.

How to Choose Tooth Form of Tungsten Carbide Saw Blade?

- Details

- Category: Tungsten Information

- Published on Sunday, 05 July 2020 13:08

How to choose tooth form of tungsten carbide saw blade? There are many kinds of tooth forms for tungsten carbide saw blades, including flat teeth, trapezoid flat teeth, left and right teeth, dovetail teeth, inverted trapezoidal teeth, and so on. Well, how to choose tooth form of tungsten carbide saw blade?

How to Choose Tooth Number of Tungsten Carbide Saw Blade?

- Details

- Category: Tungsten Information

- Published on Sunday, 05 July 2020 13:06

How to choose tooth number of tungsten carbide saw blade? Normally, the more tooth number of tungsten carbide saw blade, the better the cutting performance. However, the large number of cutting teeth means that the price of the saw blade is higher.

Tungsten Carbide Saw Web

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2020 13:45

Tungsten carbide saw web is the most commonly used cutting tool for processing wood products, and is often used for sawing and grooving metal materials. The quality of such a saw web is closely related to the quality of the workpiece to be processed. In other words, choosing a suitable tungsten carbide material to manufacture tungsten carbide saw blades is important for improving the quality of workpieces, shortening processing cycles, and reducing processing costs.

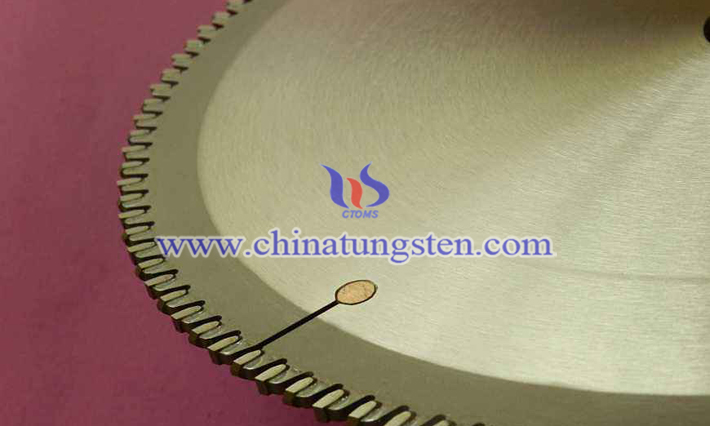

Tungsten Carbide Fan-shaped Blade

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 July 2020 13:43

Tungsten carbide fan-shaped blade has the characteristics of high hardness, high compressive strength, high temperature resistance, good wear resistance, good chemical stability (acid resistance, alkali resistance, high temperature oxidation resistance), low impact toughness, small thermal expansion coefficient, and long working life.

sales@chinatungsten.com

sales@chinatungsten.com