Tungsten Copper Used in Vacuum Switch (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 26 February 2016 17:10

- Written by xiaobin

- Hits: 230

Tungsten copper composite material has high hardness, high melting point, high strength and sweating property so that it can be widely used in high temperature, military fields, aeronautics and astronautics, vacuum switch, electronic packaging, EDM electrode and so on. Here we highlight tungsten-copper composite material in vacuum switch electrical aspects. Theoretically, vacuum switch is a kind of pressure in the vacuum system for the protection of the automatic controller, small size, excellent performance, stability, ease of maintenance and long service life. It can be widely used in various industrial automation environments, such as water utilities, petrochemicals, railways, military, pipelines, ships and so on.

When the vacuum pressure is greater than the set point, the controller will automatically cut off the circuit, signals, to ensure the normal operation of the system. When the pressure in the system is higher or lower than the safe pressure, pressure sensor immediate action within the controller, the controller makes contact on or off, the device stops working; When the pressure within the system to a safe pressure range of the device, the pressure sensor inside the controller reset immediately, the contacts within the controller turned on or off, the device is working properly. In order to adapt some high-voltage as well as vacuum switch electrical demand, related researchers developed special vacuum switch of tungsten copper. It can be perfectly adapt to flammable, explosive, high temperature and low temperature, moisture, corrosive environments, and gradually dominate the high-voltage (6-35V) grid and electrification equipment.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Preparing Ammonium Paratungstate from Worn-Out Tungsten Oxide 2/2

- Details

- Category: Tungsten Information

- Published on Friday, 26 February 2016 16:38

- Written by chunyan

- Hits: 250

4) Vacuum filtration or pressing leaching, and translate the ammonium tungstate solution in a storage tank for 10~30 hours.

3. Preparation of ammonium paratungstate

1) Outlet the ammonium tungstate solution into a reaction kettle, heating to boiling, and then insulation for evaporating and concentrating till large numbers of APT crystal come into being;

2) Stop heating when the solution proportion dropped down to I.08~I.05, cooling the temperature below to 90℃ with stirring; then filtering the solution together with the APT crystal into the vacuum filtration or centrifugal, and washing with water for 3~4 times;

3) drying at the temperature of 80-130℃;

4) Cooling down and screening with 80 mesh sieve, inspecting, packaging, then we get ammonium paratungstate.

Advantages about this way to prepare ammonium paratungstate from the warn-out tungsten oxide are like bellows:

1. Save a lot of extra caustic soda, sodium carbonate and hydrochloric acid, thus reduce the cost;

2. Simplify the process to shorten the production cycle;

3. Strong acid and alkali do not used in the reaction process; therefore, the environmental costs have been reduced;

4. Save energy and pollutants discharging has been reduced.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Studying Tungsten Trioxide Structural Phase Transition Law

- Details

- Category: Tungsten Information

- Published on Friday, 26 February 2016 16:32

- Written by qiongyao

- Hits: 258

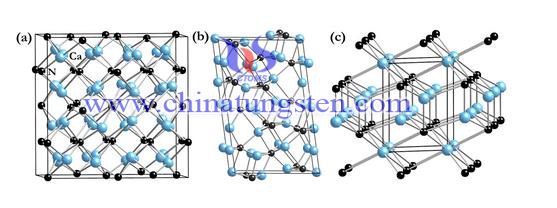

Structural phase transition region is divided into two basic types: remodeling and displacement type. Such classification is based on the grid by the formation of chemical bonds through periodic phase change. Strictly speaking, the non-reconstruction-type structural phase transitions are classified as displacement. Obviously, this is difficult to include atoms, molecules, cells and equivalent groups in a deep potential. For the reconstruction phase transition, we can include structural changes in carbon, graphite and diamond, which including the reconstruction phase transition and displacement phase transition, order - disorder phase transition, hybrid phase transition, and electron-phonon interaction associated phase transition. Of course, it does not include the superconducting phase transition, because its system structure.

Structural phase transition region is divided into two basic types: remodeling and displacement type. Such classification is based on the grid by the formation of chemical bonds through periodic phase change. Strictly speaking, the non-reconstruction-type structural phase transitions are classified as displacement. Obviously, this is difficult to include atoms, molecules, cells and equivalent groups in a deep potential. For the reconstruction phase transition, we can include structural changes in carbon, graphite and diamond, which including the reconstruction phase transition and displacement phase transition, order - disorder phase transition, hybrid phase transition, and electron-phonon interaction associated phase transition. Of course, it does not include the superconducting phase transition, because its system structure.

Structure of tungsten trioxide can be described as WO6 octahedron vertices that sharing three-dimensional network structure, however, WO3 symmetry is relatively low, because it is deformed over ReO3 structure. The lattice phonons and electronic structure of the combined effect of the changes is produced by several crystalline phases, these types of crystalline phases are the evolution from low to high symmetry with increasing temperature.

By studying the structure of the tungsten trioxide phase transformation, the phase change can be found in its crystalline order: monoclinic Pc (ε- WO3)→triclinic PT (ζ- WO3)→orthogonal Pbcn (β- WO3) →quartet P4 / ncc (α- WO3) → P4 / nmm, which presents different phase ramp in a different reaction temperature. In 2002, we found a new crystalline phase by continuous research. The high resolution neutron powder diffraction method confirms the existence of a new monoclinic phase at a temperature region of 720 ℃ to 790 ℃.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Versionhttp://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Preparing Ammonium Paratungstate from Worn-Out Tungsten Oxide 1/2

- Details

- Category: Tungsten Information

- Published on Friday, 26 February 2016 16:36

- Written by chunyan

- Hits: 270

Warn-out tungsten oxide including tungsten trioxide and blue tungsten oxide ect. which have been scrapped, and substandard thus must be reworked. This warn-out tungsten oxide which can not directly be used in tungsten smelting or other industries can be recycling. In this paper we will present a method for recovering ammonium paratungstate from warn-out tungsten oxide.

1. Handling the raw material

Screen the warn-out tungsten oxide by a 60~80 mesh sieve to remove caking tungsten oxide and mechanical inclusions; then the grinding caking tungsten oxide and also screen it;

2. Autoclaving with ammonia for preparing ammonium tungstate solution

1) Dilute the concentrated ammonia in deionized water or use water to absorb liquid ammonia, get ammonia with concentrate of 8~20%; and then formulating the slurry with stirring at the ratio that weight of tungsten oxide: volume of ammonia is 150~350g/L;

2) Add hydrogen peroxide when the material contains blue tungsten oxide, compress the kettle cover, heating to the pressure in the kettle is in the range of 4~l0kg/cm2 with stirring; the reaction time supposed to be 60~180 minutes;

3) Stop heating and cooling down to room temperature (20~40℃) after finishing the reaction; check if the color of solution is blue or not, if so, supplemented with hydrogen peroxide until it disappear; adjust the concentration of ammonia in ammonium tungstate solution among 3~5% with ammonia or water, and the concentration of WO3 is controlled among 120~350g/L;

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Inquiring Tungsten Trioxide Thin Film Translucent

- Details

- Category: Tungsten Information

- Published on Friday, 26 February 2016 16:21

- Written by qiongyao

- Hits: 231

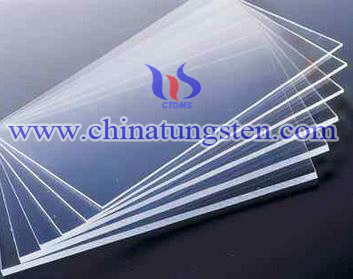

The proportion of the fabric sunlight penetrating, such as membrane light transmittance are 10-15%, which indicates that 10-15% of the sun can penetrate tensioned membrane, so that the building can save energy in the daytime without lighting. Reflection with the surface quality-related and coefficient scattering are the main factors. The density, grain boundaries and impurities are the main scattering. In the further non-ceramic cubic system, the presence of birefringence grain texture can be improved light transmittance.

The proportion of the fabric sunlight penetrating, such as membrane light transmittance are 10-15%, which indicates that 10-15% of the sun can penetrate tensioned membrane, so that the building can save energy in the daytime without lighting. Reflection with the surface quality-related and coefficient scattering are the main factors. The density, grain boundaries and impurities are the main scattering. In the further non-ceramic cubic system, the presence of birefringence grain texture can be improved light transmittance.

The tungsten trioxide thin film prepared by the sol - gel method , which shows its light transmittance is maximum and the corresponding wavelengths are 85.3%, 556nm; the peaks are and troughs are in the 350 ~ 600nm, the difference of the light transmittance at the peaks and valleys is 4.4%. WGZ-8 UV-V double beam of the incident light wavelength are 200 ~ 800nm, a light transmittance is 0% to 150% in spectrophotometer transmittance analysis.

And the use of magnetron sputtering method to prepare tungsten trioxide is different from the above, its maximum transmission rate and the corresponding wavelength ranges are: 90.1%, 572 ~ 582nm; peaks and troughs are 350 ~ 650nm, the difference between the peaks and troughs of the light transmittance is 21.2%. Comparison of the two lines shows that the difference between the two methods for preparing tungsten trioxide thin films is unlikely in the light transmittance. Thin films can be prepared by magnetron sputtering when the temperature at 450 ℃, the transmittance of the thin film is dropped by 8%. When the annealing temperature is 500 ℃, the transmittance of the thin film dropped by 8%, the peak position and peak shape are changed much.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com