Tungsten Trioxide Nanorods Synthesis

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 16:06

- Written by qiongyao

- Hits: 243

Tungsten trioxide nanorods are synthesized by 2.77g of sodium tungstate and 4.77g of sodium dissolved in 67.5ml of water , stirring, adjusting 3mol / L hydrochloric acid to pH 1.5, stirring it 30min, heating it at 180 ℃ in above solution 48h, washing three times with ethanol, drying at 65 ℃ in the environment, it can be prepared nanorods of tungsten trioxide, which is a single crystal nanorods.

Tungsten trioxide nanorods are synthesized by 2.77g of sodium tungstate and 4.77g of sodium dissolved in 67.5ml of water , stirring, adjusting 3mol / L hydrochloric acid to pH 1.5, stirring it 30min, heating it at 180 ℃ in above solution 48h, washing three times with ethanol, drying at 65 ℃ in the environment, it can be prepared nanorods of tungsten trioxide, which is a single crystal nanorods.

Tungsten trioxide nanorods are dissolved by sodium tungstate and sodium sulfate water, after stirring, adjusting the pH value, washing and drying to obtain tungsten trioxide nanorods. In the synthesis process, the selection of the sodium salt can be as director of synthesizing tungsten trioxide nanorods, and director is not the product of rod-shaped morphology.

Preparation of tungsten trioxide obtained nanorods can be observed by electron microscopy. Nanorods is 1-5μm in length, between 25-40nm in diameter, the tungsten trioxide has a high aspect ratio nanorods; the diameter of single trioxide nanorod is 30nm, the lattice fringes are clearly visible, this indicating is higher degree of crystallinity nanorods; this also shows the two intertwined lattice fringes, and hexagonal tungsten trioxide contrast can be found in the two planes are (001) and (200) planes, wherein the (001) planes are grown.

Although the tungsten trioxide nanorods preparation process shows a good prospect, it is still in the laboratory research stage. We should increase research and development, strengthen exchanges and cooperation in various fields between basic researches and make its research and application level to be improved, make it as soon as possible apply to industrial production.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coin For Graduation Ceremony

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 13:44

- Written by yaqing

- Hits: 246

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Ball High Precision Grinding Methods (2/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 February 2016 16:50

- Written by xiaobin

- Hits: 290

In this mechanism, except that the corner of the grinding disc groove diameter, V-channel angle and other geometrical parameters, but also with three abrasive disk rotational speed related. Through three platen speed adjustments can change (within the range of values of -90 ° -90 °) the angle of rotation. In addition, ball blank can be done changing the relative orientation of the spin axis of the grinding motion, its grinding trajectory line is he central axis of the shaft space sphere curve. In this way it is possible to cover the entire surface of the ball blank uniformly conducive to ball billet surface to obtain a uniform and efficient grinding. However, while this method in experiments to ensure good processing accuracy and processing efficiency, but in the actual production practice of commissioning and maintenance there are some difficulties to promote the production and use.

The double rotation grinding by the relevant domestic researchers first proposed, which is based on self-active control angle grinding, under the premise of maintaining the corner from the active control function, the upper lapping plate in the process of fixing the circumferential direction, and applied to ball billet certain elastic load, such that the larger ball blank allowance subject to greater loads, which also meet the size of the ball milled selective conditions. In addition, it uses two separate grinding trays rotating components, simplifying the mechanical structure also reduces the difficulty of assembling and processing (grinding process, the grinding tray during the grinding process does not need to rotate, so that the lower plate coaxial low requirements). But this process also has some problems, due to cobalt tungsten carbide ball in the grinding process prone to greater inertia, which will grind the whole trajectory and process have a certain impact, and high hardness of tungsten carbide cobalt will be on the ball trench uneven wear such precision can not be guaranteed.

Eccentric V-slot grinding, its axis of abrasive tray rotation and V-slot has a certain offset distance, which makes the ball billet revolution center and the center of rotation of the tray is not in the same straight line, and the contact point on the ball billet grinding tray along the upper abrasive tray radial direction. Compared with conventional V-slot grinding, it can achieve better spherical deviation. Chinese scholars also puts forward the optimization program, even if the eccentric disk and V-groove grinding discs rotate simultaneously, by adjusting the rotational speed of the upper and lower grinding disc, grinding track is sufficiently divergent, thus weakening offset the adverse effects of polishing uniformity.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Coin For Party

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 13:40

- Written by yaqing

- Hits: 273

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Ball High Precision Grinding Methods (1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 February 2016 16:49

- Written by xiaobin

- Hits: 225

Due to it has high hardness, high density and high strength, tungsten carbide ball plays an significant role in some oilfield or offshore drilling, which takes place of steel ball and ceramic ball gradually. The conventional grinding process itself due to mechanical constraints as well as some human factors can not exclude the influence can not be guaranteed tungsten carbide blank ball consistency and performance stability. Therefore, many related researchers has studied on tungsten carbide ball high precision grinding methods, which mainly includes eccentric V-slot grinding, angle of rotation controlling and double rotation grinding.

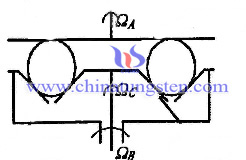

Firstly, since grinding angle active control is an idea of some of the relevant scholars from abroad first proposed, which is also known as three sets of coaxial grinding method. It is based on conventional V-slot grinding method, V-slot portion of the lower plate has been separated, so that the entire body is composed of three independently rotatable grinding disc composition, and then to adjust the ball from the corner of the blank by controlling the speed change three of grinding tray, the schematic given as follow:

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com