Ammonium Paratungstate Preparing Tungsten Rod 1/2

- Details

- Category: Tungsten Information

- Published on Thursday, 25 February 2016 17:09

- Written by chunyan

- Hits: 233

Tungsten Halogen Lamps is mainly applied in the lighting system of automotive, electronic and aerospace industry. Due to the special using environment in which the shock and vibration presence, thus the core materials-tungsten filaments is required to be with good recrystallized of dovetail joint structure, also the ratio of length and width is supposed to larger than 12, which means it has the good properties of sagging resistance at high temperature and deformation resistance. Therefore, improving the properties of tungsten bars which can improve the quality of Tungsten Halogen Lamps has become extremely urgent. A literature has proposed a method for preparing tungsten rod with good properties of sagging resistance at high temperature and deformation resistance which can applied in the production of Tungsten Halogen Lamps.

The specific steps are as follows:

1. Mix monoclinic and spherical ammonium paratungstate by the ratio of 3:1~1.5, as the raw materials;

2. Pre-reduction

Make the raw material going through a reducing furnace with four temperature zone, reduction to generate blue tungsten oxide at the hydrogen atmosphere;

3. High Potassium doping

Mix the blue tungsten oxide into a solution containing with potassium silicate and aluminum nitrate;

4. Reduction

1) Using Secondary-Reduction to generate fine grain tungsten powder with FSSS 2.0~2.6um from doped blue tungsten;

2) Generate coarse tungsten powder with FSSS 3.4~4.0um by One-Reduction method;

3) Generate medium grain tungsten powder with FSSS 2.7~3.3 um in a six temperature zone furnace by Secondary-Reduction method;

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

SEM Technique Analyzing Tungsten Trioxide Nanowire

- Details

- Category: Tungsten Information

- Published on Thursday, 25 February 2016 16:02

- Written by qiongyao

- Hits: 251

Structural Equation Modeling is a blend of multivariate statistical techniques of factor analysis and path analysis. Its strength lies in the quantitative study of the interactive relations among multiple variables. In nearly three decades, SEM is used in a large number of social and behavioral sciences, in the recent years; it has been increasingly used in market research. By SEM technique analyze of tungsten trioxide nanowire, we have a better understand that the impact of changes in external factors caused by the topography. It can be analyzed by the precursor and the reaction temperature.

Structural Equation Modeling is a blend of multivariate statistical techniques of factor analysis and path analysis. Its strength lies in the quantitative study of the interactive relations among multiple variables. In nearly three decades, SEM is used in a large number of social and behavioral sciences, in the recent years; it has been increasingly used in market research. By SEM technique analyze of tungsten trioxide nanowire, we have a better understand that the impact of changes in external factors caused by the topography. It can be analyzed by the precursor and the reaction temperature.

Nanowires may be defined as having in the transverse direction that is limited to one-dimensional structure at 100 nm (without longitudinal limit). Nanowire suspension means the end of the nanowire under vacuum. Depending on the composition of the material, the nanowire can be divided into different types, including metallic nanowires, nanowires and the insulator semiconductor nanowires.

The preparation of tungsten trioxide nanowire can be divided in three steps. Firstly, obtaining the diameter about 200-500nm tungsten trioxide nanowire, the length about 5-10μu with 1.3g of sodium tungstate reaction in the same conditions. Secondly, we can also study its effect on the appearance of the tungsten trioxide nanowires synthesized by controlling the reaction temperature. Finally, we obtain tungsten trioxide nanowires in the uniform conditions that the reaction time is 32h at 240 ℃, and its diameter is 200-500nm, its length is about 5-10μm.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

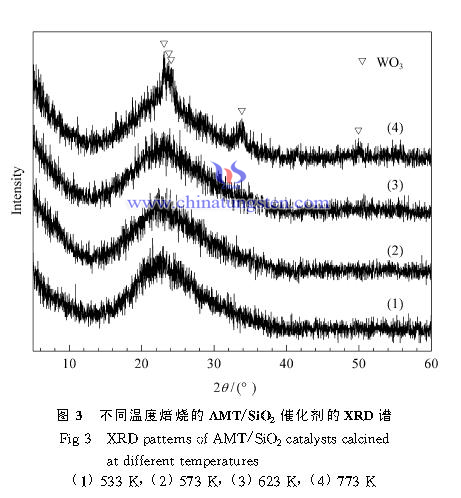

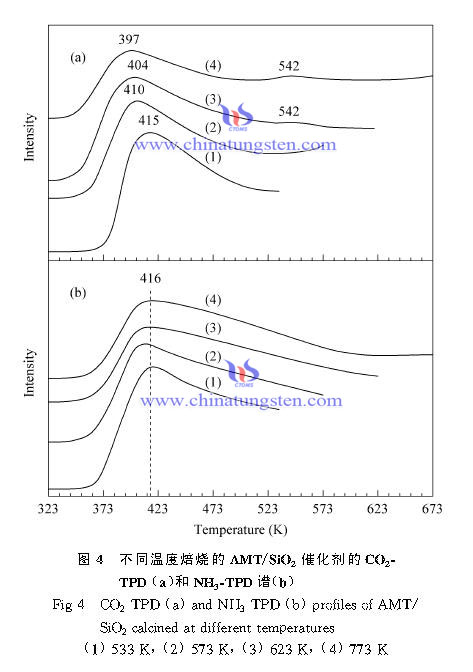

AMT / SiO2 Catalyst Characterization Results

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 18:27

- Written by xinyi

- Hits: 277

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Preparing Tungsten Trioxide Fiber

- Details

- Category: Tungsten Information

- Published on Thursday, 25 February 2016 15:52

- Written by qiongyao

- Hits: 258

Fiber refers to the material from continuous or discontinuous filaments thereof. In plants and animals, fiber plays an important role in maintaining organizations. Fibers can be woven into thin, thread and twine, paper or fabric woven fibrous mat; fibers are also used to manufacture materials, and other materials to form composite material. Natural fibers are naturally occurring, we can get fiber naturally, and fibers are divided into different types according to their origins, animal fibers, plant fibers and mineral fibers. In addition, there are chemical fibers, synthetic fibers, synthetic fibers, inorganic fibers and the like. Filling fibers can effectively improve the strength and rigidity of the plastic, reinforce plastic rigid structure.

Fiber refers to the material from continuous or discontinuous filaments thereof. In plants and animals, fiber plays an important role in maintaining organizations. Fibers can be woven into thin, thread and twine, paper or fabric woven fibrous mat; fibers are also used to manufacture materials, and other materials to form composite material. Natural fibers are naturally occurring, we can get fiber naturally, and fibers are divided into different types according to their origins, animal fibers, plant fibers and mineral fibers. In addition, there are chemical fibers, synthetic fibers, synthetic fibers, inorganic fibers and the like. Filling fibers can effectively improve the strength and rigidity of the plastic, reinforce plastic rigid structure.

Tubular tungsten trioxide nano fibers can be used to make gas sensors with high sensitivity and good stability; it shows a bright prospect in the field of gas sensor. Tubular tungsten trioxide fibers can be prepared by template method that has good controllability. This method can use its space limitations and the role of template debugging effect to control the size, morphology, structure and arrangement of the synthetic material.

Making tungstic acid as source of tungsten, placing tungsten acid in the container, and adding the container to the hydrogen peroxide and ethanol, and stirring constantly; immersing AAO template in tungsten trioxide sol about 30min, then rinsing with demonized water, and placing it about 30min in the air, and heating it at 550 ℃ for 6h in the environment, drying it, finally we can obtain similar tubular fiber tungsten trioxide .

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Producing Crystalline Ammonium Metatungstate Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 24 February 2016 18:23

- Written by xinyi

- Hits: 288

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com