Excellent Properties of TIG Welding

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:43

- Written by yiping

- Hits: 254

TIG welding has a lot of excellent properties.

1. TIG welding often uses argon as a protective gas. Argon arcs easy and stable. In addition, the density of argon is large, in the welding process can form a good protective cover, playing a good protection. And argon has large atomic mass, having a good cleaning cathode effect.

2. High weld quality, during welding process, argon gas does not react with the metal and not dissolved in the metal as well, so the whole welding process is simple main metal melting and crystallization processes, which is possible to obtain a high purity and quality welds.

3. Little welding deformation and stress, effecting by argon stream compression and cooling the arc heat is concentration, heat-affected zone very narrow, so the welding deformation and stress are small, which is suitable for sheet metal welding.

4. Easy to observation and operation, TIG welding is kind of open arc welding, so it is easy to observe, easy to operate, and suitable for all position welding.

5. Wide welding range, almost all metal materials can be welding, especially for welding lively chemical properties metals and alloys, such as aluminum, magnesium, titanium and other metals.

6. Stable arcing, TIG welding has stability current, and even in a small welding current can still stable combustion, which is suitable for thin plate materials producing.

TIG welding not only has large welding range, but also has high quality welding and can obtain high quality welds, so it is widely used in the industrial. With the development of science and technology, it is also often used as bottom welding for carbon steel and low alloy steel pressure pipe to improve the quality of welded joints.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

TIG Welding and Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:40

- Written by yiping

- Hits: 236

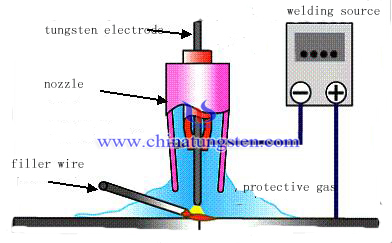

Argon tungsten-arc welding (TIG welding) is kind of welding method, which is under the protection of inert gas, the electrode and metal will produce the arc heat to melt metal and filler wire. And TIG usually uses tungsten electrode as electrode. Inert gases include carbon dioxide, argon and others. Argon as the inert gas does not react chemically with the metal, and they are able to fully protect the metal bath not to be oxidized. In addition, at high temperature argon gas does not dissolve in the liquid metal, won’t easy to produce pores. Therefore, in TIG welding argon is usually as an inert protective gas, and which can obtain high-quality welds. According to the different type of power supply, TIG can be divided into DC TIG welding, AC and pulse TIG welding three types.

In TIG thorium tungsten electrode, tungsten electrodes, cerium tungsten electrodes are generally used. To choose different electrode tpye is generally based on the welding object and different powder supply types. For example, cerium tungsten electrode is mainly used in low-current DC welding, commonly used in small parts welding; Lanthanum tungsten electrode is suitable for AC welding, having excellent welding performance, is the most popular electrode; Thorium tungsten electrode’s performance than tungsten electrode is superior and it is widely used in DC welding area, but because it has a certain degree pollution, so the waste welding head should be well handled; Zirconium tungsten electrodes in AC environment has good welding performance, especially at high load currents, the zirconium tungsten electrode exhibited excellent performance is not a substitute for the other electrodes.

Major equipments of TIG tungsten electrodes include power supply, control box, torch, hydrogen systems and air-conditioning system. TIG welding can be divided to three types according to the operation approach: manual welding, semi-automatic welding, and automatic welding which GTAW (manual welding) is most widely used.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Power Properties Test (1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:20

- Written by xiaobin

- Hits: 254

Tungsten copper powder properties itself will directly affect the final performance of tungsten copper products so that the test of tungsten copper powder raw material becomes vital. At present, laser particle size analysis, transmission electron microscope, differential scanning calorimetry are the main test methods, next we will introduce and analyze them by theory and working principle.

Laser particle size analyzer judges the size of particles by distribution (ie, scattering spectra) by the diffraction space or scattered light particles. The method combines Fraunhofer with Mie scattering theory, when a bunch of laser irradiation wavelength λ in the small spherical particles of a certain size, the beam encounters a barrier, diffraction and scattering phenomenon will occur. Generally, when the particle size is less than 10λ, the main phenomenon is scattering, while the particle size is greater than or equal to 10λ, the main phenomenon is diffraction.

The most widely used laser particle size analyzer currently usually uses 500-700nm wavelength laser as a light source, which test particles size above 5μm is relatively accurate. For particle size of less than 5μm by Mie theory is mathematically corrected, which means that for the sub-micron or nano-scale particles have a certain measure of error. In addition, theoretical model of laser particle size analysis is based on spherical particles and mono-disperse condition, and thus for the particle shape and particle size distribution will have a greater impact on the final results of particle size analysis. The more irregular shape of particle, the wider particle size distribution, the final error will be greater. For tungsten copper composite powders, the water as a dispersant and add ethanol for grinding, after 30 minutes of ultrasonic cleaning in distilled water dispersion of particle size analysis.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Power Properties Test (2/2)

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:23

- Written by xiaobin

- Hits: 252

Next, we introduce transmission electron microscope (TEM), which is a kind of high-powered high-resolution microscope. Compared with common optical microscope, it uses electromagnetic field as lens and was widely used in super-fine grain, aggregates and some nano-scale material testing. Furthermore, since the electron beam penetration is weak, so the specimens for electron microscopy of ultrathin sections shall be made about a thickness of about 50nm, which require ultra-microtome machining. For tungsten-copper powder, the thickness is more than 100nm, if the sample is required and the powder milled sample was dissolved in ethanol, in an ultrasonic cleaning after the suspension of the dispersed drops in the electron microscope with a copper medium carbon film, powder morphology was observed after drying.

Finally, thermal analysis, which refers to a change in endothermic or exothermic reactions that take place through the heating and cooling process and the quality of the material, the components was analyzed and identified substance. It includes that differential scanning calorimetry (DSC), which measuring thermal transitions within the material and relevant to the relationship between temperature and heat flow. The shape of the melting peak on DSC curve reflects the particle size distribution; the information can be drawn melting enthalpy crystallinity. Themogravimentric analysis (TGA) records that temperature changes and the time the sample quality, measurable by TGA analysis of injection molding material at different temperatures of weight loss situation, and in order to determine the heating rate of heat degreasing.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Recycling Ammonium Paratungstate, Cobalt, Nickel from Waste Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 16:23

- Written by chunyan

- Hits: 237

With the economic developing rapidly, tungsten carbide used in each industry is being more and more widely, thus leading a huge demand and consumption of tungsten. The metal composition of carbide is almost rare metal elements, and tungsten takes a large proportion. The more consumption of carbide means the more consumption of rare metals, in this case, recover tungsten and other rare metals is extremely important.

With the economic developing rapidly, tungsten carbide used in each industry is being more and more widely, thus leading a huge demand and consumption of tungsten. The metal composition of carbide is almost rare metal elements, and tungsten takes a large proportion. The more consumption of carbide means the more consumption of rare metals, in this case, recover tungsten and other rare metals is extremely important.

The steps of recovery waste tungsten carbide are like bellows:

1. Melting tungsten carbide

Pour the waste tungsten carbide scrap into a furnace, and adding sodium bicarbonate or sodium carbonate, then heating to 800~1200℃ to get carbide mixture;

2. Preparation of sodium tungstate

Pour the carbide mixture into water to generate a solution containing with sodium tungstate and precipitate, and then filter to separate sodium tungstate solution and solid matter;

3. Preparation of ammonium paratungstate

Sodium tungstate solution goes through extraction and adding ammonia to generate ammonium tungstate solution, heating to evaporate APT crystal;

Further more, the APT is dried, and calcination to obtain tungsten oxide, and then reduced to tungsten powder in a hydrogen atmosphere;

4. Extract cobalt, nickel and other metals from the solids

1) Mix the solid with hydrochloric acid solution (concentration of 10-30%), and then filter to separate the precipitate and liquid;

2) Taking liquids, removing the impurities of iron, and then carrying out extraction to separate liquids containing with cobalt and nickel;

3) Add ammonium oxalate solution respectively into the liquids containing with cobalt and nickel, and precipitation, filtration, evaporation and drying after the reaction is completed, to obtain solids that cobalt and nickel oxalate, then reduced to obtain cobalt and nickel powder;

4) Take the precipitate to calcine and melt for second time, and then get tantalum and niobium by dissolving it in water.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com