Tungsten Carbide Anti-corrosion Research (1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 17:11

- Written by xiaobin

- Hits: 252

Conventional tungsten carbide is composed of hard phase WC and the binder Co. Due to Co has good wettability on WC, tungsten carbide has high hardness, high density, high strength and excellent chemical stability, which can be widely used in some wear parts and cutting tools machining. But as binder, Co has poor anti-corrosion, especially for scour corrosion so that to add some other elements with good anti-corrosion or to find new binder becomes the new directions of related researchers. The principle of Co oxidation corrosion of WC and Co is formed of two electrodes in the electrochemical etching solution, to form a closed loop enclosing an electrolyte. WC as a catalyst to promote the electrolytic solution boundaries O2, producing O2-, forming a cathode; Co as the anode is oxidized and causes the corrosion.

The Common nickel (Ni) can effectively take place of the cohesive effect of cobalt (Co) and improve the anti-corrosion of tungsten carbide. But tungsten carbide hardness (HRA) affected its formation, as compared to the original cobalt tungsten carbide decreased 0.5-1 times, only 70-80% strength cobalt tungsten carbide, which is only suitable for less demand in strength, wear resistance situations. In addition, add chromium (Cr) in the binder is also a kind of common method to improve anti-corrosion of tungsten carbide. It can remarkably decrease the corrosion rate of tungsten carbide in corrosive conditions, refine tungsten carbide grains and strengthen the binder phase, which not only improve the anti-corrosion of tungsten carbide, but also promote other properties.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

AMT Production Technical State

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 16:54

- Written by xinyi

- Hits: 264

| AMT Supplier: Chinatungsten Online www.ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode–Balled, Pointed or Truncated Shape

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 16:42

- Written by yiping

- Hits: 404

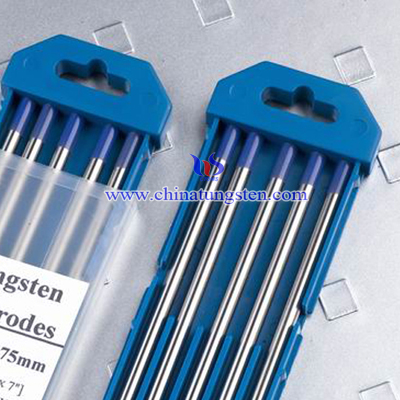

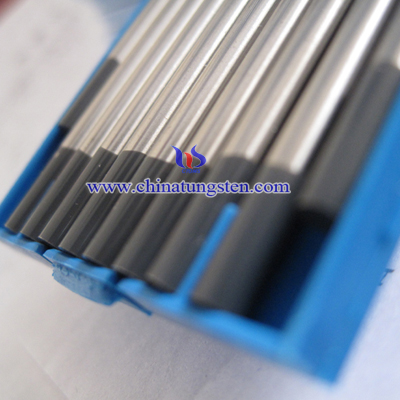

As we know, different type and shape of tungsten electrode you used will influence the arc quality and welding performance that you will achieve. This article will brief introduce the performance and usage tip of different tungsten electrode shape.

A balled tip is generally used on a pure tungsten electrode. Besides, it is suggested for use with the AC process on sine wave and conventional squarewave TIG welders. What’s more the diameter of the balled end should not exceed 1.5 times the diameter of the tungsten electrode. Because a larger sphere at the tip of the electrode can reduce arc stability and/or fall off and contaminate the weld.

A pointed or truncated tip is generally used on pure tungsten electrode, ceriated tungsten electrode, lanthanated tungsten electrode and thoriated electrode. And a pointed or truncated tip of electrode should be used for inverter AC and DC welding processes. To process electrode tip to a pointed or truncated shape should use a grinding wheel specially designated for tungsten grinding which can avoid contamination and one that is made of borazon or diamond which can resist tungsten’s hardness. Note: if you are grinding thoriated tungsten, make sure you control and collect the dust, have an adequate ventilation system at the grinding station and that you follow manufacture’s warnings, instructions and MSDS sheets. What’s more, during grinding should put the tungsten electrode straight on the wheel versus at a 90-degree angle to ensure that the grind marks run the length of the electrode. So it will reduce the presence of ridges on the electrode that could create arc wandering or melt into the weld puddle, causing contamination.

Generally, when welding with lower currents on thinner materials, it is best to use the pointed tungsten electrode. Because A pointed tungsten allows the welding current to transfer in a focused arc and helps prevent thinner metals, such as aluminum, from becoming distorted. However, using pointed tungsten for higher current applications is not recommended. Because, at the higher current it can blow off the tip of the electrode and cause weld puddle contamination. So at the higher current, truncated tip will more suitable than pointed shape.

In any application, different type and shape of tungsten electrode has distinct advantages and disadvantages. That’s why, regardless of type of material you are TIG welding or whether you are using an AC or DC process, it is always important to choose tungsten electrode shape and type. Doing so can maximize your TIG welding success and is one of the best defenses against contamination and rework.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Materials Analysis

- Details

- Category: Tungsten Information

- Published on Monday, 14 March 2016 16:48

- Written by yiping

- Hits: 275

Tungsten electrode material having strong electron emission ability, high elastic modulus, low vapor pressure and other good properties, so often as thermal electron emitting material used in various different areas. It also as an important part used in TIG welding, plasma welding and cutting. The minimum amount of pure tungsten electrode is 99.5%. It has a higher electron work function, so it is difficult to arcing and arc beam is instability. Besides the service life is short. The shortages of pure tungsten electrodes greatly limited its application.

Tungsten electrode in order to meet the development of modern industry, from the production process and raw materials employs a lot of analysis and breakthroughs. For example, base on the shortage of pure tungsten electrode some researchers have produced a new type tungsten electrode-rare earth tungsten electrode. Rare earth tungsten electrode uses tungsten as substrate, doped with some rare earth oxides which have low electron work function, common rare earth tungsten electrodes including: thoriated tungsten electrodes, ceriated tungsten electrodes, lanthanated tungsten electrodes, zirconiated tungsten electrodes and so on. Different types rare earth tungsten electrodes having different properties can select them according to the welding material and current conditions.

With welding industry continuous development, the reliability and stability of the electrode made more stringent requirements, on this basis, invented a new tungsten electrode type-composite rare earth electrodes. The study found arcing performance and properties of the composite electrode materials are better than rare earth tungsten electrodes, and ternary composite tungsten electrode property is better than binary composite tungsten electrode.

At present, China has less research on rare earth tungsten electrode and composite rare earth tungsten electrode. Besides, the production process of them is not mature, lacking large-scale development and promotion. China has rich resources of tungsten ore and rare earth resources, we have the advantage for large-scale electrodes production, if tungsten electrode materials research and development, China's tungsten electrode industry will be able to grab opportunities in the global market, has broad market prospects.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Warm Compacting Process Impact on Tungsten Copper Density (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 11 March 2016 18:10

- Written by xiaobin

- Hits: 244

In addition, it is necessary that consider the glass transition temperature of the temperature and pressure of the main component of the binder, temperature and pressure temperature closer to the glass transition temperature, the better the viscous flow of the binder can form a good lubricating film on the particle surface, effectively reducing inter particle internal friction and external particles and mold wall friction, effectively increasing the density of tungsten and copper compacts. When temperature and pressure temperature exceeds the glass transition temperature of the binder, the binder near the melting point, viscosity decreases, lubrication is no longer obvious, friction coefficient rises, effectively suppress power drops down so that the compact density decreases.

Theoretically, for pressing pressure, the density of material by PM is increasing with the increasing pressing pressure. However, increasing the pressure is having some limitations, first of all it is necessary to subject to the applicable conditions of tolerance and mold equipment. Besides, the pressure should be chose according to the impact on tungsten copper compacts. By contrast green density at room temperature and pressure different pressing force, both of which are rising as the pressing pressure, green density increases. But at the same compaction pressure units, the density of tungsten copper green by warm compacting process is higher than the density of tungsten-copper compacts by cold compacting process. This is due to the molding temperature and pressure present in the adhesive film surface of the particles can effectively reduce the particle relative displacement resistance when pressing the powder particles are better able to transmit pressure, increasing the effective pressing pressure, which will help increase the density of compacts.

Furthermore, in the process of warm compacting process, the yield strength and hardening rate of metal powder grains decrease, which increases the plastic deformation of powder particles and is beneficial for improving the density of green. Concerning powder compacting law, many experts and scholars propose some famous equation of repression, combined with the requirements of production equipment as well as the relative performance of tungsten copper required, thereby rational use of temperature and pressure molding process to improve its green density.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com