Tungsten Carbide Button Processing Optimization (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 16:36

- Written by xiaobin

- Hits: 267

Tungsten carbide button is mainly composed of tungsten carbide (WC) + cobalt (Co), WC is hard phase, and Co is soft phase (binder). They complement each other so that tungsten carbide buttons have better hardness, wear resistance and toughness than other materials, which accelerates the drilling, improves the efficiency and extends the service life of tools. In order to improve overall properties of tungsten carbide buttons, we can optimize from two sides, one is to optimize the raw materials of tungsten carbide itself (grain refinement, structure optimization and trace elements adding), another is to optimize the processing, which includes LP-HIP (Low Pressure – Hot Isostatic Pressing), quenching-aging treatment and shape of button optimization, etc.

After sintering, tungsten carbide button will leave some porosity and internal defects, which decreases the toughness and strength of tungsten carbide buttons. Through many experiments, HIP successfully applied in tungsten carbide buttons production. HIP (Hot Isostatic Pressing) refers to place the products in a closed container, the pressure is applied equally to each of the products, while applying heat, under the action of high temperature and pressure, and make the products densified. In addition, HIP can also be directly involved in the powder molding, powder put into the sheath (mold), wrap can be used metal or ceramic production (low-carbon steel, Ni, Mo, glass, etc.), and then use the nitrogen N2, or Ar gas atmosphere, the powder is directly heated and pressurized sintering the powder metallurgy process.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide Crystalline Form Affects Tungsten Carbide Property

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 16:30

- Written by Cristina

- Hits: 284

Under certain conditions the six-phase tungsten oxide(h-WO3)can exist in stable form. When annealing temperature exceeds 400℃, it can turns into monoclinic system(γ-WO3). Nano tungsten oxide applied in electric and optical field is different from tungsten oxide bulk. The main differences are phase transition temperature drops evidently, so sometimes orthorhombic tungsten oxide(β-WO3)appears and is stable under room temperature.

Chemical stoichiometric number of tungsten oxide seems simple, its phase transition and structure change is complex. The ideal tungsten oxide is octahedron, W6+ exists in the center part of it. O2 as anion distribute in the other eight edges. Actually, W6+ often deviates from the center part, the whole structure turns into tetragonal crystal(α-WO3), temperature range is T>740℃. For orthorhombic system, 740℃>T>330℃; monoclinic system: 330℃>T>17℃ and triclinic system: 17℃>T>-43℃.

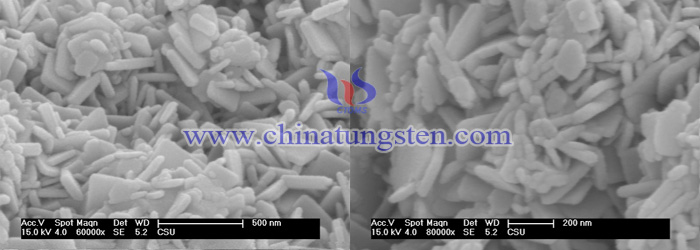

Below are SEM graphs of tungsten oxide, testing equipments are: ICP-AES Spectrograph, X-ray Powder Diffractometer, TSM-6360 LV scanning electron microscope, MICROPLUS laser diffraction particle size analyzer.

In a word, tungsten oxide has various crystalline forms, its transition can affect its property, tungsten oxide crystalline form can largely affects tungsten carbide property. Due to this factor, tungsten oxide can be applied in many fields because of its multi-properties.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Doped Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 11:56

- Written by yiping

- Hits: 255

With the continuous development and progress of the welding industry, the reliability and stability of the electrode material is proposed more stringent requirements. Rare earth doped tungsten electrode with its high melting point, low electron work function, excellent thermal electron emission property, as the main material in place of thorium tungsten electrode. Besides, it successful replaces thoriated tungsten electrodes used in the small-scale welding. But in AC it has poor arcing property, short service life and other problems. In general, the arcing performance of the tungsten electrode doped with three rare earth oxides is superior to tungsten electrodes doped with single rare earth oxides. In rare earth doped tungsten electrode, ternary complex is better than binary complex.

In the late 1980s, a group of Japanese scholars have made some progress in the development of new tungsten electrode material, particularly in rare earth doped tungsten electrode material. They have operated a lot of work on electrode component design, performance comparison and mechanism study found tungsten electrode doped with two rare earth oxides can improve the performance of the tungsten electrode. For the binary rare earth tungsten electrodes, CeO2: Y2O3 = 1: 3 (CeO2 0.5%, Y2O3 1.5%), Ce2O3: La2O3 = 1: 1, La2O3: Y2O3 = 1: 3, has better performance and durability property. 1: 3 (La2O3 + Y2O3) tungsten electrode after 4h (180A) arcing still has good performance and arcing 10h durability remains better condition than single rare earth doped electrode.

For the ternary tungsten electrodes, the best rare earth oxide ratio is CeO2: La2O3: Y2O3 = 1: 1: 3. This electrode having good operating performance can sustain 10h (180A) operating. In rare earth doped tungsten electrodes, this electrode having low operating temperature, high electron emissivity, lowest electron work function and other properties, the overall performance is more prominent.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Doped Tungsten Electrode Introduction

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 12:00

- Written by yiping

- Hits: 248

Thoriated tungsten electrodes exists radioactive and long-term using will harm to humans and the environment, therefore developed rare earth doped tungsten electrodes having a similar performance with thorium tungsten electrodes use in welding field. Rare earth doped tungsten electrode having high melting point, low work function and good welding performance and gradually become the new favorite material in welding, cutting, thermal spraying and vacuum electric field.

Tungsten electrode doped with single rare earth oxides

Tungsten electrode doped with single rare earth oxides was first invented in the 1980s. It doped rare earth oxide La2O3, Y2O3, CeO3 into tungsten oxide after reduction, sintering and machining to produce a variety of tungsten electrodes. In practice, we found that this electrode have good arcing and welding property. Tungsten electrode doped with single rare earth oxide is suitable for small current welding. But in high current it service life is not long and the electron emission stability is poor.

Tungsten electrode doped with two rare earth oxides

Tungsten electrodes doped with two rare earth oxides were developed in the 1990s, primarily in order to improve the limitations of the single rare earth doped electrodes. Tungsten electrode doped with two rare earth oxides can carry large current and has large applications range. It has better overall performance than single rare earth doped tungsten electrodes. However, it has poor processing property.

Tungsten electrode doped with three rare earth oxides

Tungsten electrode doped with three rare earth oxides arcing performance, static characteristics and anti-burning property is superior to thoriated tungsten electrode. However, it has poor processing property.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Cesium Tungsten Bronze Nanopowder in Transparent Insulation Coating

- Details

- Category: Tungsten Information

- Published on Thursday, 17 March 2016 17:29

- Written by xinyi

- Hits: 265

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com