Rare Earth Effect in Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Monday, 28 March 2016 16:13

- Written by yiping

- Hits: 246

Among tungsten electrodes, thoriated tungsten electrode, having good weldability, is the most widely used tungsten electrodes. But because thorium has radioactive contamination so in the production and using process will endanger human health and pollute the environment. Through continuous research and development, the researchers developed multiple composite rare earth tungsten electrodes, and it is considered the best material to replace thoriated tungsten electrodes.

Rare earth doped as the active material doped to tungsten matrix can effectively reduce the work function of the tungsten electrode material to improve the welding performance. In multiple composite rare earth tungsten electrodes, the doped rare earth elements include La, Y and Ce. These three different rare earth elements at different temperatures have diffusion rates. Among these elements, Ce first diffused to the surface, reducing the work function of the surface, so click arc easy. When arc burning stable, La has largest surface coverage, and plays an important role at this process. While working in high current, Y timely migration to the surface, so the electrode can stably operate at high current conditions. Synergy of these three rare earth elements, so that the performance of multiple composite rare earth electrodes better than thoriated tungsten electrode.

On the other hand, the rare earth is conducive to refine reduction powder, and easy to promote the β-W formation. β-W makes the sintering process not easy to control. In the tungsten electrode sintering process, not only the rare earth will impede tungsten grain growth, but it will improve the recovery and recrystallization temperature of tungsten electrode such that the deformation resistance increases of electrode will increase, resulting in sintering process not easy to control. This is also one of reasons that multiple composite rare earth tungsten electrode has low finished produced rate and high production costs.

In the future, studies should toward production technology development direction to research. To improve the multiple composite rare earth tungsten electrodes finished produced rate and to reduce production costs make it more widely used.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Porous Titanium Dioxide V2O5-WO3 Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 28 March 2016 16:00

- Written by chunyan

- Hits: 245

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

CsxWO3 Influence on NIR Shielding Property

- Details

- Category: Tungsten Information

- Published on Friday, 25 March 2016 19:40

- Written by xinyi

- Hits: 253

Near-infrared(NIR, IR-A DIN), is defined by the water absorption, and commonly used in fiber optic telecommunication because of low attenuation losses in the SiO2 glass (silica) medium. Image intensifiers are sensitive to this area of the spectrum. Examples include night vision devices such as night vision goggles.

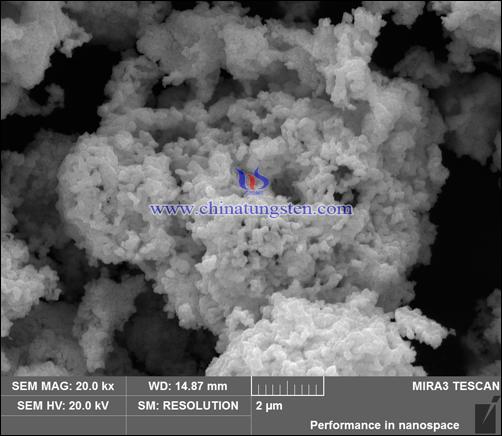

Recently, shielding not only ultraviolet rays but also infrared rays has been attracted attentions in terms of saving resource and energy and creating comfortable life space. Cs doped tungsten bronze (CsxWO3) which has suitable amounts of free electrons in crystal is one of the candidate materials of inorganic infrared rays shielding materials, since it can shield ultraviolet and infrared rays by interband transition and plasma oscillation of free electrons, respectively. Nanoparticles of CsxWO3 particles were synthesized by solvothermal reaction of WCl6 and CsOH・H2O in ethanol and ethanol aqueous solutions at 200 ℃ for 12-47 h. After that, CsxWO3 particles were heated in 500 ml/min NH3 gas flow at 400 ℃ for 1 h. Sheet-like and rod-like nanopartricles of CsxWO3 were synthesized in ethanol and 42.9 vol% ethanol aqueous solution at 200 ℃, respectively. The samples formed in 42.9 vol% ehanol aqueous showed higer crystallinity but lower Cs/W atomic ratio than those in ethanol. Sheet-like particles showed higher visible light transparency, while rod-like particles showed more excellent infrared shielding properties, indicating that rod-like particles were more suitable for shielding infrared rays. Moreover, the visible light transparency and infrared shielding properties could be improved by improving the dispersion state of the particles by agitating with ZrO2 beads. The electric conductivity of the pressed pellet of rod-like particles could be increased by heating in NH3 gas atmosphere at 400 ℃.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Aluminum Oxide Improves Tungsten Trioxide SCR Denitration Catalyst Activity

- Details

- Category: Tungsten Information

- Published on Monday, 28 March 2016 15:56

- Written by chunyan

- Hits: 280

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Cs(x)WO3/ZnO Nanocomposite as Smart Coating

- Details

- Category: Tungsten Information

- Published on Friday, 25 March 2016 19:33

- Written by xinyi

- Hits: 228

A novel CsxWO3/ZnO smart coating was proposed to achieve multiple functions, such as heat insulation, photodecomposition of toxic NO gas, blocking of harmful UV light, etc. In this composite coating, CsxWO3 nanorods were used as a NIR and UV light shielding material while ZnO nanoparticles were utilized as a photocatalyst and a material to enhance visible light transmittance and block UV light. When the mass ratio of CsxWO3/ZnO was 1, the composite coating possessed a very good visible light transmittance of over 80% and an excellent UV-shielding ability. This novel coating showed heat insulation that is superior to the ITO coating and photocatalytic decontamination of NO gas that is superior to the standard TiO2 (P25). The proposed CsxWO3/ZnO smart coating is a promising material not only for energy saving but also for environmental cleanup.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com