Pisces Tungsten Gold-Plated Coin

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 11:59

- Written by yaqing

- Hits: 241

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Aquarius Tungsten Gold-Plated Coin

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 March 2016 11:57

- Written by yaqing

- Hits: 310

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate Preparing Tungsten Bismuth Light Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 19:05

- Written by chunyan

- Hits: 228

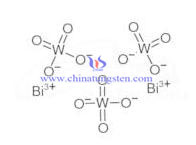

Handling the environmental pollution is the focus and urgent problems for human today, especially governance of organic pollutants. Photocatalytic technology has the advantages that low energy consumption, clean mild conditions, no secondary pollution, etc. in purify organic pollutants, being a green environmental control technology which has a broad application prospect. Tungsten bismuth (Bi2WO6), as a new type of bismuth series light catalyst, is a multi-compound with layered structure. And because of its high catalytic activity under visible light irradiation, it can decompose water to produce oxygen and degradation of organic matter, making it particularly suitable for environmental pollution control and solar energy conversion.

Handling the environmental pollution is the focus and urgent problems for human today, especially governance of organic pollutants. Photocatalytic technology has the advantages that low energy consumption, clean mild conditions, no secondary pollution, etc. in purify organic pollutants, being a green environmental control technology which has a broad application prospect. Tungsten bismuth (Bi2WO6), as a new type of bismuth series light catalyst, is a multi-compound with layered structure. And because of its high catalytic activity under visible light irradiation, it can decompose water to produce oxygen and degradation of organic matter, making it particularly suitable for environmental pollution control and solar energy conversion.

Studies have pointed out a method that uses ammonium paratungstate as a raw material for preparing bismuth tungstate with three-dimensional wheel-like hierarchical structure. The steps are as follows:

1. Dissolving the bismuth salt in dilute aqueous acid to form a clear solution;

2. Dissolving ammonium paratungstate by a certain percentage in deionized water to obtain APT aqueous solution;

3. Add APT solution slowly into the clear solution obtained in Step 1, and continue stirring for 0.5~l hour to obtain solution named A;

4. Dissolving an amount of sulfate in deionized water, and slowly adding it into solution A, and continue stirring for 0.5~l hour, to obtain solution named B;

5. Transferring B solution into a stainless steel autoclave containing Teflon-lined, and heated to 150~200°C for 10~30h, to generate products;

6. The products is washed and carried out centrifugation, and dried under vacuum at 50~100°C, to obtain the bismuth tungstate with three-dimensional wheel-like hierarchical structure.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Paratungstate Preparing ZrWMoO8 Composite Ceramic Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 19:22

- Written by chunyan

- Hits: 237

The problem of thermal expansion is an unfavorable factor in many areas, which is widely existing in function and structure materials such as precision components, optical fiber, circuit boards, sensors and fuel cells. ZrWMoO8 composite ceramic material is an ideal expand controllable material.

Studies have pointed out a method that ammonium paratungstate preparing ZrWMoO8 composite ceramic material, the steps are as follows:

1. Weighing zirconium oxychloride, aluminum nitrate and dissolving them into 100~150mL of distilled water to prepare a solution A;

2. Dissolving ammonium paratungstate, tetra-hydrate ammonium molybdate, ammonium metavanadate into 100~150mL of distilled water, and heated with stirring to completely dissolve, then to obtain solution B;

3. Both solution A and B are slowly dropped with the same speed into a round-bottomed flask which is containing 50mL of ethanol, then white precipitate comes into being, stirring is supposed to be continually during the addition for ensuring mixing homogenous;

4. Transferring the solution to an evaporator for evaporation after the addition was completed, and then drying, milling to get a mixed powder;

5. Placing the powder in a muffle furnace at 550~650°C calcined for 2~3 hours, and then taking out to cool down to obtain a precursor;

6. The precursor powder is placed in a mold to form cylindrical specimens;

7. The precursor sample was placed in a molybdenum crucible with stamped, and placed into another ceramic crucible with a lid, the ceramic crucible is place into the resistance furnace when its temperature heated to 940~970°C. The ceramic crucible is calcined for 2 hours, and transferred into a dryer to cool down to room temperature after taken out and cooled down for 2 minutes, then we obtain the ZrWMoO8 composite ceramic material.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Ceramic Nano Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 17:03

- Written by xinyi

- Hits: 235

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com