Tungsten Carbide Buttons Wear Resistance Analysis (1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 March 2016 16:49

- Written by xiaobin

- Hits: 274

With the developing technology and exploration, more and more machines or tools required working in strict conditions, such as high-pressure sealing, acid or alkali corrosion and so on. Tungsten carbide buttons have high hardness, high density, high strength, high melting point and excellent chemical stability, which can be widely used in mine, oil fields drilling, tunnel and rock stratum drilling.

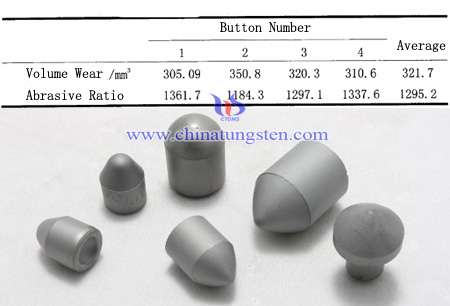

Domestic scholars have done a lot of research, who use tungsten carbide buttons for granite grinding experiments. In the experiments, they use vertical lathe as the equipment, fix the invasion depth of tungsten carbide buttons that is the effective stress acting on the buttons, the grinding line speed to detect tungsten carbide buttons wear resistance. Although tungsten carbide button has higher hardness, it belongs to brittle materials, which working wear by friction is proportional to the amount of wear and tear theory calculation formula brittle relationship can be drawn carbide button wear volume of its units. The smaller the amount of wear of friction units of work, the greater tungsten carbide button abrasion and wear and abrasion resistance is inversely proportional to the volume. The statistics of tungsten carbide button volume wear and abrasive ratio given as follow:

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com