Tungsten Copper Sheet Sintering Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 June 2016 14:55

- Written by xiaobin

- Hits: 284

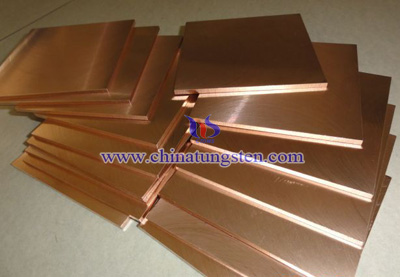

Tungsten copper materials perfectly combine high hardness, high melting point, high strength, low coefficient of thermal expansion and excellent wear and corrosion resistance of W with high plasticity and excellent thermal and electrical conductivity of Cu. Furthermore, it has another advantage that other material difficult to achieve: there is a great difference in the melting point between W and Cu (W-3380℃, Cu-1083℃), at a temperature exceeding the melting point of Cu, copper evaporation can take away the most of heat and keep the matrix working normal. So it is also called sweating heat sink material.

With the development of electronic devices now tend to be miniaturized and high-power, heating and cooling is an inevitable process of the devices. Tungsten copper alloy with superior performance to meet the cooling requirements of high-power devices, and it may also adjust the coefficient of thermal expansion, and microelectronics devices of different semiconductor materials are well matched connection, so as to effectively prevent heat stress thermal fatigue damage caused. Therefore, in some LSI (large-scale integrated circuit) and high-power microwave devices, tungsten copper sheet has a broad prospect in electronic packaging substrates, heat sinks, connectors and other microelectronic housing material.

Theoretically, as heat sink material, tungsten copper sheet has a strict requirement of theoretical density, usually higher than 98% and the thickness less than 1mm, which conventional PM (powder metallurgy) is difficult to meet the increasing requirements. Recent years, the relevant researchers and scholars have studied in ultra-fine powder fabrication, densified process and alloy molding technology. For tungsten copper sheet sintering process, Surface wettability of densification, microstructure and properties of the alloy a great impact, and tungsten copper two-phase sintering temperature depends on the wettability of tungsten and copper two phases. Through the experiment can be found that sintered at 1200 ℃, tungsten particles agglomerate, with copper and tungsten particles did not enter the group, there are many small voids between the particles of tungsten and copper group phase, which indicates Cu has poor wettability at this time; when sintering temperature up to 1300℃, the wettability of Cu has improved, so it can immersed in the tungsten particles, which is beneficial for flowability and rearrangement of W grains. With the increase of sintering temperature, then Cu phase occurs gathering, that is copper pool of depression phenomenon, inter tungsten particles re-agglomerate and grow interconnected to provide the conditions so that the density of tungsten copper alloy in high temperature sintering stage quickly increase.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Bar and Doping Bubble

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 June 2016 10:16

- Written by xuejiao

- Hits: 285

In the early 1900s, the United States developed a high temperature anti-drooping tungsten wire. Doping (semiconductor), intentionally introducing impurities into an extremely pure semiconductor to change its electrical properties. After many tests, it is found that its sagging resistance is due to a small amount of silicon, aluminum, potassium oxide in the tungsten oxide before reduction. Among them, the researchers proposed a "bubble statement." "Bubble statement" holds the view that the dopant is prone to have the doping effect in the first reduction process, and then form the doping bubble during the vertical melting. These bubbles will be stretched, annealed in follow-up processes. Then it will become small holes arranged in clusters, but these holes may have an impact on the cross motion of tungsten filament grain boundaries during the second recrystallization, or even hinder its movement, eventually leading to the tungsten wire forming a especial recrystallized grain structure, which would make wolfram filament have a high temperature sagging resistance. Anti-sagging tungsten filament is mainly used for incandescent, fluorescent and other light bulb and the heat wire of tube. Anti-sagging tungsten wire of automobile and motorcycle lights is one of the most important applications. There are many methods to detect its anti-sagging performance, the most common ways include high-temperature creep test, high temperature bending drop method (V-shaped test), etc.

In the early 1900s, the United States developed a high temperature anti-drooping tungsten wire. Doping (semiconductor), intentionally introducing impurities into an extremely pure semiconductor to change its electrical properties. After many tests, it is found that its sagging resistance is due to a small amount of silicon, aluminum, potassium oxide in the tungsten oxide before reduction. Among them, the researchers proposed a "bubble statement." "Bubble statement" holds the view that the dopant is prone to have the doping effect in the first reduction process, and then form the doping bubble during the vertical melting. These bubbles will be stretched, annealed in follow-up processes. Then it will become small holes arranged in clusters, but these holes may have an impact on the cross motion of tungsten filament grain boundaries during the second recrystallization, or even hinder its movement, eventually leading to the tungsten wire forming a especial recrystallized grain structure, which would make wolfram filament have a high temperature sagging resistance. Anti-sagging tungsten filament is mainly used for incandescent, fluorescent and other light bulb and the heat wire of tube. Anti-sagging tungsten wire of automobile and motorcycle lights is one of the most important applications. There are many methods to detect its anti-sagging performance, the most common ways include high-temperature creep test, high temperature bending drop method (V-shaped test), etc.

Through the preliminary calculation of the test, it can be concluded that the effective conductive cross section area of tungsten bar would significantly reduced if content of potassium increasingly. Because residual potassium will evaporate into gas in a sintering process, and then produce large amounts of adulterate bubble, resulting in a reduction of its effective conducting cross-sectional area. When potassium content is lower than 70ppm, change of density of adulterate bubbles is more pronounced, it would reduced rapidly as decreasing of potassium content, which will reduce the high temperature sagging resistance of tungsten filament.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

When Formaldehyde Meets Tungsten Trioxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 May 2016 18:30

- Written by chunyan

- Hits: 263

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Bar - Indirect Heating Sintering

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 June 2016 10:10

- Written by xuejiao

- Hits: 286

Tungsten bar can be used for the manufacturing process of tungsten filament. So far, most factories adopt vertical sintering method. Such method is working in a water cooling bell, but there is no equipment to keep warm in this bell. Then a large amount of thermal energy generated by electric power are used for heating water, but hot water need cooling device for cooling, this process will consume a lot of power. The temperature field gradient of this method is relatively large, resulting in the density, grain size and degree of porosity of the same batch of tungsten are different. What’s more, density of both ends of the billet is very low, so they must be removed, so that it would waste a part of resources.

Tungsten bar can be used for the manufacturing process of tungsten filament. So far, most factories adopt vertical sintering method. Such method is working in a water cooling bell, but there is no equipment to keep warm in this bell. Then a large amount of thermal energy generated by electric power are used for heating water, but hot water need cooling device for cooling, this process will consume a lot of power. The temperature field gradient of this method is relatively large, resulting in the density, grain size and degree of porosity of the same batch of tungsten are different. What’s more, density of both ends of the billet is very low, so they must be removed, so that it would waste a part of resources.

To a certain degree indirect heating sintering method can solves these drawbacks, it also improve their quality of billet, which has an excellent energy saving effect. In 1976, an intermediate frequency (IF) induction sintering furnace had been already developed, this device will be able to meet the conditions of uniform temperature field for sintering the tungsten bar. It adopts a tungsten tube as a heating element, and jargonia is a heat insulating material. A sealing member consists of them, the heat energy generated by electrical energy will be surrounded by the sealing member, and concentrated in the middle of the furnace for sintering the wolfram bar.

Horizontal can keep consistent with vertical properties of the bars prepared by this method. In addition, this kind of bars would have a uniform and thin microstructure. The density of both sides of billet does not have a great difference with other parts, so they are not need to be removed. IF induction furnace indirectly heating tungsten products would ensure the stability of its quality, and the more important point is that it can save resources, which plays an important role in environmental protection.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Encounter Tungsten Trioxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 May 2016 18:27

- Written by chunyan

- Hits: 251

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com