Tungsten Carbide Die Status Quo

- Details

- Category: Tungsten Information

- Published on Thursday, 16 June 2016 16:00

- Written by xiaobin

- Hits: 243

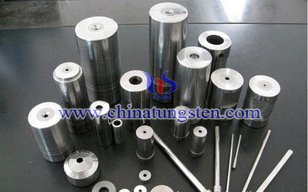

Currently, tungsten carbide material has become an indispensable role in the mold manufacturing. With the increasing complexity of the products and the higher requirement of the performance, the relevant researchers develop new carbide materials research as one of the directions. Several years ago, new carbide material mainly used Fe, Ni to replace Co, which usually used for cold heading die and cold extrusion die with high demand of toughness (such as YG15, YG20, YG25). Recent years, the hotpot turns to ultrafine grained and nano-crystalline carbide and gradient structure of cemented carbide. Fine-grained and ultrafine grain cemented carbide has been available, as YG8 fine grain carbide drawing dies in less than 1mm wire control, efficiency is three times the normal drawing die. Gradient cemented carbide is also divided into content gradient and structure gradient, they often fabricated by metal solution penetrated treatment. In addition, cast tungsten carbide heat die has a better performance in tube and wire rolling.

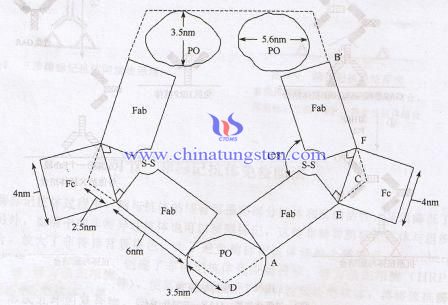

Based on the mechanism of tensile deformation of the metal mold uneven wear, Researchers have proposed the maximum and minimum drawing angle theory. They found that the gap between domestic and foreign mold die life lies in the angle of the design. Foreign mold at the bottom of the mold core and the mold housing bore center of the bottom-contact parts adopt double convex design, it is possible to force the center of the largest snug fit around the pore and for an interference fit. So some domestic manufactures have also been inspired, and correspondly make some improvements in the structure. Especially the improvements on the design of hexagonal carbide die, which changed into six casement combination so that it can save the consumption of tungsten carbide and convenient for assembling and changing. In terms of machining and assembling technologies, tungsten carbide usually uses hot or cold casement and vacuum brazing.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Die Description

- Details

- Category: Tungsten Information

- Published on Thursday, 16 June 2016 15:58

- Written by xiaobin

- Hits: 276

Compared with conventional steel die, WC-Co tungsten carbide die has many advantages, such as high density, high hardness, high strength, low coefficient of thermal expansion, excellent wear and corrosion resistance and so on, whose service life is several times longer than the steel die. Common used tungsten carbide die grades are YG3, YG6, YG6X, YG8, YG15, YG20, YG20C, YG25, etc, and some non-magnetic alloy die materials. According to the different applications, tungsten carbide dies can be divided into tungsten carbide drawing die, cold heading die, non-magnetic die, thermal die, etc.

Tungsten carbide drawing die takes the major part and it plays an important role in metal processing by the external force is a pressure force by the metal mold, the metal cross-section is compressed so as to obtain a desired cross-sectional shape and size. Due to plastic and steel die has bad performance in wear resistance and service life, and although diamond drawing die has high hardness and wear resistance, it cost a lot. In summary, tungsten carbide drawing die has excellent properties and medium cost, which is the major part of drawing die materials; Cold heading die and stamping die are mounted on the respective use of machinery by applying a deforming force, the blank pre-formed. Carbide material hardness and excellent wear resistance, life million times in 5000-6000, the size does not substantially change, so as to effectively guarantee the dimensional accuracy of the product; No-magnetic alloy die generally used for the production of magnetic materials. Before non-magnetic tungsten carbide non-magnetic appearing, people has been using non-magnetic steel, mold its poor performance, low hardness and short life, the inner wall of the mold used for a period of time after a serious nap and deformation phenomena, so that the dimensional accuracy and surface quality of the magnetic material has been greatly affected. Non-magnetic carbide prepared by strictly controlling the carbon content and adding trace elements (Cr, Mo, Ta, NiB, Al, VC), which can replace the steel and improve the efficiency.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Cesium Tungsten Bronze Ultrafine Powder Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 June 2016 18:05

- Written by xinyi

- Hits: 326

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

CsxWO3 Type Peroxide Mimic Enzyme

- Details

- Category: Tungsten Information

- Published on Thursday, 16 June 2016 15:48

- Written by xinyi

- Hits: 274

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide Thin Film Electrode Cyclic Voltammetry

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 June 2016 17:27

- Written by Cristina

- Hits: 432

To study the cyclic voltammetry of tungsten oxide thin film electrode, use three-electrode system, sulfuric acid solucion as electrolyte, the property is observed by measuring light current. Below is cyclic voltammograms of WO3 thin film electrode being heat treatment under 450℃ under dark and 500W xenon light source (light strength 100Mw/cm2). We can see that under darkness the polarization current of electrode is small within the scanning range, it is far smaller than anode polarization current under light. Photoelectrochemical reaction under light has good reversibility. Within electric potential 0.35~1.2V(vs.Ag/AgCl), cathode Pt and anode WO3 thin film electrode reaction is as following:

Anode:2OH-+ h+ → O2 ↑+ 2H+

Cathode:2H+ + 2e- → H2 ↑

When exposed to light, if the applied bias is low, the Fermi level of WO3 is higher, electrolysis solution accepter is easier to trap photo electron near WO3 electrolyte interface of electrode, so the photo current of anode is weaker, even comes close to 0. With the increasing of bias, Fermi level of WO3 decreases as well, the accepter of electrolyte to trap the photo electron is getting harder which makes the photo electron largely spread to the electric substrate. When bias comes to a certain level, the extra electric filed enlarges the migration rate of photo electron, so photo current of anode strengthens with the shuffling of current.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com