Tungsten Oxide Nanotube

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 17:35

- Written by Cristina

- Hits: 276

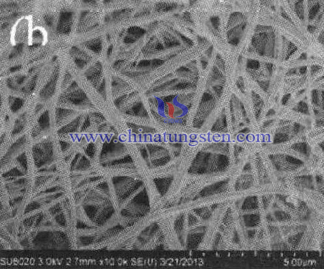

When particle size of some material reaches to nano grade (1~100nm), it can show many special reactions. It can be widely applied in functional information display, catalyst, magnetic material. Among which, tungsten oxide has various crystalline structure, it has a large amount of non-stoichiometry oxide form and has multi-functional broad-band gap semiconductor material. WO3 is widely applied in gas sensor, photocatalyst, gasochromism, electrochromism, photochromism and solar cell due to its unique electricity, optical configuation, and magnetic property. Apart from that, temperature induces structure phase transition which results in the changes of volume, resistance and color greatly draw people’s attention. The research on its special structure has become the focus of recent study.

The traditional preparing method of tungsten oxide nanotube need extra coating and sculpture process, the quality of nanotube greatly depends on the control of processing steps. By coaxial electrospinning, hollow nano fiber can be obtained, manufacturing process is simplified.

Raw material: PVA; ammonium metatungstate; absolute ethyl alcohol; aluminum foil; deionized water.

Preparing process:

(1) Weigh a certain amount of PVA to dissolve in deionized water, stirring it for 4hous in constant temperature of 80℃ and prepare it to 15% PVA solution. Then add 24ml alcohol and 6g ammonium metatungstate solution into 60ml PVA solution.

(2) Dilute another 15% PVA solution to 10% as inner pipe solution by deionized water. Inject both inner and outer pipe solution into injector, then inject them into electrostatic spinning coaxial needle.

(3) Under electric voltage 9~15kV, keep spinning with receiving distance of aluminum foil for 10~12cm. Dry the obtained composite fiber in thermotank for 12 hours, keep the temperature to 600℃ by putting it in muffle furnace, and then cool it down to get WO3 nanotube.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding Used For Sterile Insect Technique

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 17:17

- Written by minghui

- Hits: 288

The sterile insect technique is a biological insect control method that uses radiation source to irradiate injurious insect, resulting in dominant lethal mutations in the body of insects (ie, chromosome breakage) and causing the abnormal mitotic, then overwhelming numbers of sterile insects are released into the wild. The released insects are normally male, as the females cause the damage usually by laying eggs in the crop. The sterile males compete with wild males to mate with the females. Females that mate with a sterile male produce no offspring, thus reducing the next generation's population. Repeated release of sterile males can diminish small populations, although success with dense target populations has not been demonstrated. The sterile insect technique has the advantage of strong specificity, and can avoid the resistance to drugs generated by the application of pesticides to prevent insects.

The sterile insect technique is a biological insect control method that uses radiation source to irradiate injurious insect, resulting in dominant lethal mutations in the body of insects (ie, chromosome breakage) and causing the abnormal mitotic, then overwhelming numbers of sterile insects are released into the wild. The released insects are normally male, as the females cause the damage usually by laying eggs in the crop. The sterile males compete with wild males to mate with the females. Females that mate with a sterile male produce no offspring, thus reducing the next generation's population. Repeated release of sterile males can diminish small populations, although success with dense target populations has not been demonstrated. The sterile insect technique has the advantage of strong specificity, and can avoid the resistance to drugs generated by the application of pesticides to prevent insects.

The radiation sources used by sterile insect technique are mainly α-rays, β-rays, γ-rays and neutrons, these rays all belong to ionizing radiation that has ionization effect and will cause some harm to human body. When the body is subjected to the radiation exposure, dizziness, fatigue, headache, memory loss, vision loss, sleep disorders and other symptoms will appear, and the radiation will affect the human reproductive system, circulatory system, immune system, metabolic system, cardiovascular system, resulting in children's mental defects, cancer, leukemia and other diseases. Therefore, people should pay attention to use radiation shielding to shield radiation in the use of inherited sterility technique for the prevention of pests.

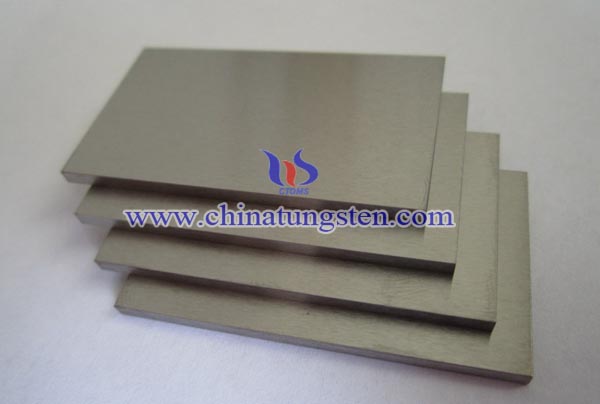

Tungsten alloy shielding can be used for shielding the radiation generated in the use of inherited sterility technique. Studies have shown that the radiation shielding capability of a material is closely related to its density, the higher density means a better radiation shielding capability and radiation absorbing ability. Compared to other radiation shielding materials (such as lead), tungsten alloy has a higher density, so that tungsten alloy shielding has better radiation shielding capability.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Nuclear Technology And Tungsten Alloy Shielding

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 17:14

- Written by minghui

- Hits: 278

Nuclear technology refers to the modern new and high technology and one of the signs of social modernization which is based on the nuclear reaction, nuclear properties, nuclear effect and nuclear spectroscopy, and with radiation source, nuclear radiation detector, accelerator and reactor as its tools. Nuclear technology is an important method for early diagnosis of certain cancers, coronary heart disease and brain dysfunction. Its sensitivity, selectivity, specificity, interference, penetrating are so high that it is widely used in various fields of national economy as well as medical care, food preservation, agriculture, industry and hydrology aspects. Nuclear technology can be divided into military nuclear technology, nuclear power and civilian nuclear technology, of which civil nuclear technology is the most active, including radiopharmaceuticals, radiation processing technology, nuclear diagnostic technology, nuclear instrumentation, nuclear analytical techniques.

Nuclear technology refers to the modern new and high technology and one of the signs of social modernization which is based on the nuclear reaction, nuclear properties, nuclear effect and nuclear spectroscopy, and with radiation source, nuclear radiation detector, accelerator and reactor as its tools. Nuclear technology is an important method for early diagnosis of certain cancers, coronary heart disease and brain dysfunction. Its sensitivity, selectivity, specificity, interference, penetrating are so high that it is widely used in various fields of national economy as well as medical care, food preservation, agriculture, industry and hydrology aspects. Nuclear technology can be divided into military nuclear technology, nuclear power and civilian nuclear technology, of which civil nuclear technology is the most active, including radiopharmaceuticals, radiation processing technology, nuclear diagnostic technology, nuclear instrumentation, nuclear analytical techniques.

Nuclear technology not only has brought a variety of convenient, but also brought the nuclear radiation. For the question about the long-term effects of nuclear radiation on people, the study of Atomic Energy Commission geneticist James • Nair and his colleagues shows that the probability to have cancer for the people surviving from nuclear radiation is higher than ordinary people. In fact, many survivors suffered from thyroid cancer, lung cancer, breast cancer, leukemia and other cancers, and some people suffered from mental abnormalities after Hiroshima and Nagasaki nuclear explosions suffered. Many examples show that pregnant women subjected to nuclear radiation can lead to fetal malformation, fetal death and other diseases.

Tungsten alloy shielding can effectively shield the nuclear radiation generated in the use of nuclear technology to avoid it causing harm to humans. Since tungsten alloy combines high density, good machinability, good corrosion resistance, high radiation absorption capacity and high intensity, it is the best raw materials for radiation shielding. In the situation of reducing the volume and thickness of shielding, the radiation shielding performance of tungsten alloy shielding is still equivalent to that of lead. In addition, compared to lead and depleted uranium, tungsten alloy is more environmentally friendly.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Oxide Nanorod

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 17:16

- Written by Cristina

- Hits: 283

Since indium storage property of nanocrystalline transition metal oxide (MO,M=Co, Ni, Cu, Fe) is found, other transition metal oxide such as CuO, Fe2O3, Fe2O4, Co3O4, WO3 can be transited by chemical reaction MOx+2xLi+=M+xLi2O. Its capacity is far better than graphite anode material in lithium ion battery. Among which WO3 is the most stable oxide of tungsten under room temperature. It is not only environmental friendly, but also is cheap. It has potential to be widely applied as lithium ion battery anode material. However, WO3 in lumpish has low electric conductivity, its volume changes greatly during charge-discharge process. Thus results in the instability of WO3. One of the improving methods is to synthesis WO3 nano material of different appearance. Then lithium storage property of the material is improved.

Preparing method: By hydrothermal method, tungsten oxide nanorod can be prepared on the indium tin oxide substrate.

Raw material: Sodium tungstate (AR: analytically pure); NaCl (AR); oxalic acid (AR); methylene blue (AR); hydrochroric acid. All solution is prepared by deionized water. ITO electric glass is under ultrasound for 10min in acetone, ethyl alcohol and deionized water, then dry it.

Preparing process:

(1) Dissolve 8.25g sodium tungstate in 25ml deionized water, then adding hydrochloric acid to adjust PH value into 2.0.

(2) Then dilute the solution to 250ml, put in PH meter, adding oxalic acid into solution, adjust PH value to 2.3, the precursor solution is obtained.

(3) Adding 0.3g sodium chloride into hydrothermal reactor, put in the ITO glass and make sure it is slanted. Then adding 20ml precursor solution, sealed it and thermal reacting for 4 hours under 170℃.

(4) After the reaction is done, cool it down to room temperature. Clean the ITO with deionized water and dry it. Tungsten nanorod of even size and bigger density is obtained.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Heater for Evaporation Coating

- Details

- Category: Tungsten Information

- Published on Monday, 06 June 2016 10:10

- Written by xuejiao

- Hits: 233

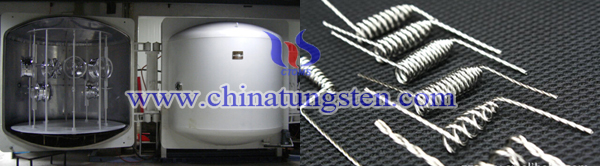

Vacuum evaporation coating has developed rapidly in recent years, glass, plastic, ceramic, metal, and other based material can be coated. Aluminum, copper, silver and their alloys can also be used as the coating material. Most vacuum aluminizing technology use tungsten wire as a heating source (tungsten heater). First of all, the plated workpiece should be clean, load it on a shelf in a sealed room. Accordance to the classification of application, coating machines have been designed into a stationary, rotating and both revolution and rotation and other types. The wolfram heater can be inserted in the position that is close to the plated object, when the degree of vacuum is higher than 5 × 10-4 Torr, the tungsten wire is energized and heated, the molten aluminum will be evaporated into an aluminum atom, and it will condense on the surface of the plated object, forming bright and non-transparent film with 3-5 microinch.

According to statistics, the amount of interpreters which need tungsten heater for vacuum coating is constantly increasing in China. And in order to save the use of silver, China continues to promote the new technology of vacuum aluminizing mirror. And vacuum evaporation coating machine in has been widely used in China. What’s more, the amount of using of tungsten heater is also increasing year by year. United States, Japan, Sweden, Germany and other countries still use wolfram heater, so exports are also on the rise.

Secondly, use value of high quality wolfram heater is twice as much as the poor quality wolfram heater, so improving the quality of wolfram heater has an important influence. In order to reduce the consumption of tungsten, it needs to improve the quality and its reasonable application. If the use of wolfram heater can be stabilized at around 18 times in a week, then the product will be able to meet customer needs.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com