Cesium Tungsten Bronze Powder and Function Film Preparation

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 June 2016 17:45

- Written by xinyi

- Hits: 301

The present invention is preparing cesium tungsten bronze powder through the reactant control, combined with hydrothermal be prepared to effectively simplify the preparation process and reduce the cesium tungsten bronze powder production costs. And in this particular hydrothermal reaction conditions produced cesium tungsten bronze infrared, near-infrared shielding particularly excellent performance.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Picks Failure Mode

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 June 2016 16:16

- Written by xiaobin

- Hits: 297

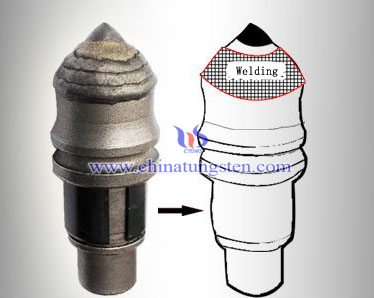

Tungsten carbide picks are composed of carbide button by the brazing alloy and structural steel, generally used for direct shearer cutting, coal mining, so it is also known as coal buttons. Tungsten carbide picks cut coalseam by impact rotation, which requires withstanding high pressure, shear stress and bending stress at the same time. Not only periodic and alternating impact load, in the process of drilling the friction heat seam cutter and intense friction will be also produced, and throughout the wear process also may be accompanied by local yielding, more contact with the mechanical behavior of fatigue, corrosion and breakage.

Take YG11C tungsten carbide mining button as example, from the fracture of buttons after failure, in the coal excavation process, due to impact load surface at high pressure stress, carbide cutter block collapse occurred. Because coal seam geological uncertainties, buttons can not be held in the excavation and seam completely good contact, and mixed with a certain seam gangue, which also makes poor contact or even inevitable increase the area of contact does not occur. Such a state of stress in the alternating load impact effect is prone to fatigue and thermal fatigue cracking. Furthermore, tungsten carbide pick will be damaged by the stress concentration caused by micro defects on the surface or inside tube.

According to the failure modes and the reasons of tungsten carbide picks, we can improve the properties by adjusting the particle size, the composition and the proportion. First of all, Co content should not be too low, because it can improve the thermal fatigue, enhance plasticity, stress relaxation of the alloy and so on. But increasing Co content will have an influence on the wear resistance to some extent, according to the hardness of the coal seam, generally controlled between 8%-13%. Next, the granularity of WC grains and the proportion is also significant, fine grain WC particles total surface area decreases, the specific surface area increases, the mean free path of Co improves, the equivalent profile improves Co content, will help to improve the fracture toughness of the alloy. In order to enhance Co phase, the use of appropriate heat treatment process is a relatively effective way, and use the existence of polymorphic transition phase to produce other enhanced face-centered cubic cobalt, so as to achieve the purpose of toughening carbide picks.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Nano Material Photocatalytically Splitting of Water into Hydrogen

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 June 2016 17:56

- Written by Cristina

- Hits: 300

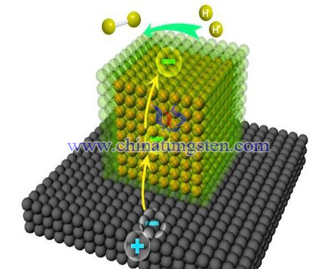

WO3 nano material has the advantages of innocuous and unpoisonous, easy to produce, stable property, cost efficient, visible light response. It is a kind of ideal photoanode semiconductor material in photoelectrochemistry reaction and is widely used in photoelectrochemistry field (photocatalytic water splitting, photocatalytic organic pollutant and solar cell.

In 1972, Fujishima and Honda firstly reported that under lighting conditions, using photoelectrochemistry cell composed by TiO2 semiconductor electrode to decompose water into hydrogen and oxygen. From then on many scientific researchers did a lot of study on other oxide semiconductors to photocatalytically splitting of water into hydrogen.

Decompose 1mol H2O into hydrogen and oxygen need 273kJ power under normal condition, which equals to 2.46eV. Voltage needed for common electrolysis of water reaction is 1.23V. So if using semiconductor to phorocatalytically decompose water, the theoretical band gap of material should be higher than 1.23eV. In actual reaction, the overpotential and electrode polarization may cause losing power, so the band gap should be 2.0~2.2eV.

According difference in structure of material, the band gap of WO3 is 2.5~2.8eV, it is an ideal photocatalytically splitting water material. Research shows that when pH=0, electrode potential at the bottom of conduction band of WO3 is +0.4V which is higher than regular value, so it can not be used in oxygen evolution reaction. However, due to the strong oxidizability of valance, it can be used to produce oxygen by decomposing water.

In 1976, scientist Hobes from Israel firstly used WO3 in photocatalytically splitting of water into hydrogen. Compared to TiO2 photocatalyst, light conversion rate of WO3 is lower. But WO3 has advantages like innocuous and unpoisonous, easy to produce, stable property, cost efficient, visible light response. Besides that, in actual photocatalytically splitting water, WO3 can maintain favorable anti light corrosive property and optical electronic transmission under strong sun light. Thus it is a kind of ideal photocatalyst for splitting water.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding Used For Agriculture

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 June 2016 17:57

- Written by minghui

- Hits: 276

With the development of radiation technology, it is widely used in various fields. In the medical field, it is used to diagnose the abnormal changes in tissues and organs of the body and cancer therapy; in industry, it is used in the automated quality control of industrial production line and the detection of the casting crack and weld crack; in the food safety, it is used for food preservation, food sterilization; in agriculture, it is mainly used for radiation breeding, isotopic tracing and radiation disinfestation. Among them, radiation breeding is the use of ionizing radiation to treated with crops to induce mutations, then choosing good variation individuals to cultivate to obtain new varieties; isotopic tracing is the technology that introduce the radioisotope into the body of plants and animals, and then research the growth rhythm or the absorption condition of nutrition of plants and animals by using the radiation detector to track the absorption, accumulation and transfer conditions of isotopes in the body; while the radiation disinfestation is a method that uses radiation source to irradiate injurious insect, resulting in dominant lethal mutations in the body of insects and causing the abnormal mitotic, then overwhelming numbers of sterile insects are released into the wild.

With the development of radiation technology, it is widely used in various fields. In the medical field, it is used to diagnose the abnormal changes in tissues and organs of the body and cancer therapy; in industry, it is used in the automated quality control of industrial production line and the detection of the casting crack and weld crack; in the food safety, it is used for food preservation, food sterilization; in agriculture, it is mainly used for radiation breeding, isotopic tracing and radiation disinfestation. Among them, radiation breeding is the use of ionizing radiation to treated with crops to induce mutations, then choosing good variation individuals to cultivate to obtain new varieties; isotopic tracing is the technology that introduce the radioisotope into the body of plants and animals, and then research the growth rhythm or the absorption condition of nutrition of plants and animals by using the radiation detector to track the absorption, accumulation and transfer conditions of isotopes in the body; while the radiation disinfestation is a method that uses radiation source to irradiate injurious insect, resulting in dominant lethal mutations in the body of insects and causing the abnormal mitotic, then overwhelming numbers of sterile insects are released into the wild.

Tungsten alloy shielding is widely used in the agriculture field due to its excellent radiation shielding performance. Radiation can cause harm to human body by accelerating the decline of the cells, causing cell abnormalities or inhibiting the generation of new cells, or causing changes in the body's biochemical reactions. Long-term exposure to radiation can also lead to serious damage to human organs and systems, as well as causing leukemia, cancer, reproductive system diseases, aplastic anemia and other diseases. Thus, people should pay attention to use the tungsten shielding for the application of radiation technology in agriculture to shield and absorb radiation. Scientists have discovered that the radiation shielding property of a metal material increases with its density, the higher density means the better radiation absorption capacity and radiation shielding ability. Compared to other traditional materials (such as lead), tungsten alloy has higher density, therefore tungsten alloy shielding has better radiation shielding performance. And tungsten alloy shielding is non-toxic and is extremely environmentally friendly shielding material.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Plutonium-239 Tungsten Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 June 2016 17:54

- Written by minghui

- Hits: 1579

Plutonium-239 is a fissile isotope of plutonium with a half-life of 24,110 years, which is mainly used for the production of fissile material or other materials, or used for industrial-scale irradiation. Due to plutonium-239 can produce large amounts of pure plutonium-239 at a lower cost than the high enriched uranium -235, it is also widely used in nuclear weapons and nuclear power plants. Plutonium-239 is artificially produced by fast neutrons in reactor to bombard uranium - 238, a fissile plutonium-239 atom can produce 207.1 MeV energy. In the reactor, the uranium-235 atoms yield two or three neutrons which would be absorbed by uranium – 238 to produce plutonium-239 and other isotopes. In fact, the role of production reactor is to burn part of the uranium-235 in exchange for plutonium-239, and per burn of a uranium-235 atom will get eight plutonium-239 atoms. Plutonium-239 can also absorb neutrons and has the least critical mass in all commonly used nuclear fuel.

Plutonium-239 is a fissile isotope of plutonium with a half-life of 24,110 years, which is mainly used for the production of fissile material or other materials, or used for industrial-scale irradiation. Due to plutonium-239 can produce large amounts of pure plutonium-239 at a lower cost than the high enriched uranium -235, it is also widely used in nuclear weapons and nuclear power plants. Plutonium-239 is artificially produced by fast neutrons in reactor to bombard uranium - 238, a fissile plutonium-239 atom can produce 207.1 MeV energy. In the reactor, the uranium-235 atoms yield two or three neutrons which would be absorbed by uranium – 238 to produce plutonium-239 and other isotopes. In fact, the role of production reactor is to burn part of the uranium-235 in exchange for plutonium-239, and per burn of a uranium-235 atom will get eight plutonium-239 atoms. Plutonium-239 can also absorb neutrons and has the least critical mass in all commonly used nuclear fuel.

Plutonium-239 is toxic, and can emit α particle. α particle is mainly consist of two protons and two neutrons, which is equivalent to the kernel of helium 4 or helium 4 after ionization(i.e., He2 +). Generally the chemical element which is radioactive and has a larger atomic weight can emit α particle through α decay to convert into lighter elements, until the element is stable. Since the volume of α particle is larger and it has two positive charges, it can easily ionize other substances. Once the radioactive materials that can emit α particles (such as radiation fog) are inhaled or eating by human, α particle can damage organ cells directly. Although the penetrating power of α particle is weak, its strong ionization ability to cause harm to biological organism is no less than that of other radiation.

Plutonium-239 tungsten radiation shielding is used to shield the radiation produced by the radioactive isotope plutonium-239. Compared with the conventional shielding materials (such as lead), tungsten alloy shielding reflects good radiation shielding effect. Lead is early used in the shielding field, but a discovery shows that the radiation shielding performance of lead shielding is not high enough and it can also seriously pollute the environment. Under the condition of the same thickness, the radiation shielding capability of the tungsten shielding is twice as good as lead shielding.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com