Research on the Sintering Process of Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 15:18

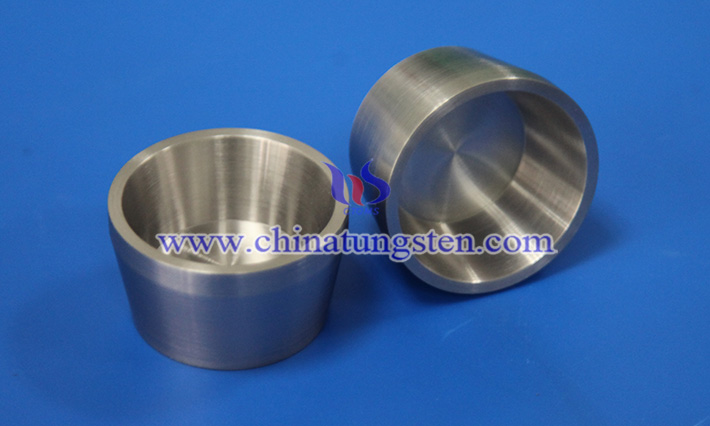

Due to the high melting point of tungsten itself, it is difficult for the traditional casting and molding method to be directly applied to the manufacture of crucibles, so the sintering process has become one of the main methods for preparing tungsten crucible. In this paper, we will focus on the sintering process of crucibles, and discuss its process flow, key parameters, technical challenges and optimization directions.

1. Preparation and molding of raw materials before sintering

The first step in the sintering process is the preparation of tungsten powder. High-quality tungsten powder is usually prepared by the method of reducing tungsten oxide hydride (WO₃ or WO₂.₉), and its particle size, specific surface area and loose density have a significant effect on the density of subsequent sintering. In order to produce crucibles with high density and low porosity, ultrafine tungsten powder with a particle size of 1–5 μm is usually selected.

This is followed by a molding process, with common methods such as isostatic pressing (CIP), compression molding, and injection molding. Isostatic compression molding can achieve uniform compaction under irregular crucible geometry and is the most commonly used method at present. By applying an isostatic pressure of 200–400 MPa, the powder is uniformly compacted in the mold, providing a good basis for subsequent high-temperature sintering.

2. Control of key parameters of high-temperature sintering

Tungsten is sintered at temperatures up to 2000–2200°C and is usually carried out in a hydrogen or vacuum atmosphere to avoid oxidation and contamination by impurities. The sintering process is usually divided into the following stages:

Pre-firing stage (1200–1600°C): mainly excludes residual moisture, organic binders and gases inside the compact;

Heating to sintering temperature (1800–2200°C): significant diffusion occurs between particles, resulting in neck formation and growth, reduced porosity, and volume shrinkage;

Holding phase (30–120 minutes): Promotes grain growth and pore closure to further increase density.

During the whole sintering process, the purity of the hydrogen atmosphere should be controlled at more than 99.999% to avoid oxidation of tungsten caused by oxygen or water vapor. If vacuum sintering is used, the system pressure should be controlled below 10⁻³ Pa to reduce the evaporation rate of tungsten and reduce surface activity.

3. Common sintering problems and solutions

Common problems faced by crucibles during the sintering process include:

Insufficient density: mainly caused by uneven particle size of powder or insufficient molding pressure. Compactness can be improved by using ultra-fine uniform tungsten powder, increasing cold pressing strength, or using hot isostatic pressing (HIP).

Surface roughness or sintering deformation: It may be due to unreasonable mold design or too high sintering temperature. The use of optimized mold design, controlled ramp rates, and the use of auxiliary sintering dies can help improve surface quality.

Grain coarseness: In high-temperature and long-term sintering, tungsten grains are easy to grow and cause material embrittlement. Grain size can be effectively controlled by adding a small amount of grain inhibitors (e.g., rare earth oxides) or by introducing a two-step sintering method.

4, the application and exploration of advanced sintering technology

In recent years, advanced sintering technologies have been introduced to further optimize crucible performance, such as:

Hot Isostatic Pressing (HIP): Heating and high pressure are applied at the same time to achieve higher density, reduce porosity and improve mechanical strength at lower temperatures;

Discharge Plasma Sintering (SPS): Uses pulsed currents to promote sintering diffusion, which helps to shorten sintering time and inhibit grain growth;

Gradient sintering: By controlling the temperature gradient of different parts, the crucible structure forms an optimized transition between the thickness or the bottom and the side wall, and improves the thermal shock resistance.

5. Post-sintering treatment process

After high-temperature sintering, tungsten crucible usually needs to undergo a series of machining treatments, including internal and external surface turning, polishing, dimensional correction, etc., to meet the needs of precision applications. In addition, surface strengthening coatings (e.g. TiN, ZrO₂) can be used to further improve the oxidation resistance and service life, especially for multi-cycle heating applications.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com