The Key Role of Tungsten Crucibles in the Growth of Single Crystal Growth

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 15:16

Monocrystalline materials occupy a core position in high-tech industries such as semiconductors, optoelectronics, lasers, and aerospace, and their crystal quality directly affects the performance and reliability of terminal devices.

In order to obtain high-purity, high-consistency, and high-defect controlled single crystal materials, crystals need to be grown in extreme temperatures and highly controllable environments.

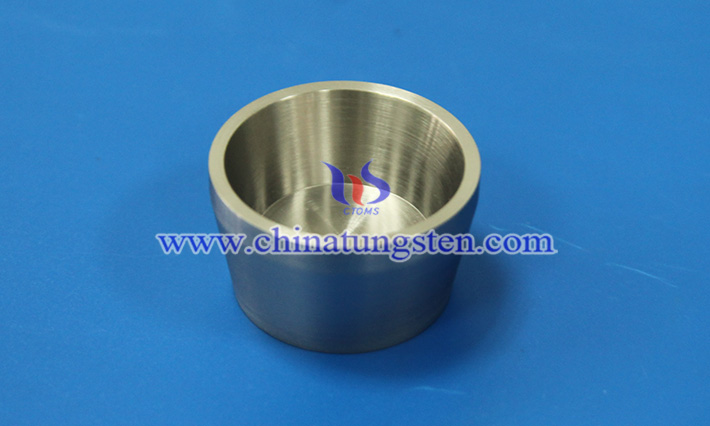

In the whole single crystal preparation system, tungsten crucible has become an irreplaceable key component due to its unique physical and chemical properties. It not only plays the role of containing and protecting the melt, but also plays a core role in multiple dimensions such as thermal field control, crystallization process stability, and impurity control.

1. The physical characteristics of tungsten crucible support the high-temperature growth environment

As one of the metals with the highest melting point, tungsten can work stably for a long time in a temperature environment of more than 2000°C, which is ideal for companies such as sapphire (Al₂O₃), silicon carbide (SiC), germanium oxide (GeO₂), and gallium nitride (GaN) and other materials with high melting points are critical for single crystal growth. Taking sapphire crystal growth as an example, its melting point is about 2050 °C, which is difficult for traditional quartz and platinum metals to withstand such high temperatures, while W crucibles can provide sufficient thermal stability to ensure the safety and continuity of crystal growth.

2. Excellent chemical inertness ensures crystal purity

At high temperatures, most metal containers are susceptible to chemical reactions with melts, resulting in impurity doping or crystal defects. Tungsten, on the other hand, is extremely chemically inert in a vacuum or inert atmosphere (such as argon), which can effectively avoid reacting with crystalline materials and greatly reduce the introduction of impurities. This is essential for single crystal materials that require extremely high purity (e.g., germanium, silicon, GaAs, etc.) for semiconductors. In addition, tungsten is not easily soluble in common melt systems and does not migrate into the crystal as a doping source, helping to maintain the intrinsic properties of the crystal.

3. Important role in the construction of thermal field

Single crystal growth technologies such as Czochralski, Bridgman, and Zone melting all have strict requirements for thermal field distribution. Due to its high thermal conductivity (about 173 W/m·K at room temperature) and low coefficient of thermal expansion (about 4.5×10⁻⁶/K), the crucible made of tungsten can conduct heat energy quickly and evenly, forming a stable temperature gradient inside the crucible, promoting melt uniformity and controlling the crystal growth interface. The higher the thermal field stability, the fewer crystal defects, the more controllable the size, and the more symmetrical the shape, which is conducive to subsequent processing.

4. The structural stability supports continuous long-term growth

Tungsten crucibles have excellent high-temperature strength and thermal fatigue resistance, and are not prone to deformation, cracking, or warping, even in continuous single-crystal growth processes. For example, during the lifting of sapphire or lithium tantalate (LiTaO₃) crystals, the growth cycle is often tens of hours or even days, and the crucible must maintain a stable shape to prevent melt leakage, crystalline interface disturbance, and growth failure. The stable performance of the crucible under these conditions makes it a reliable choice for industrial single crystal growth.

5. It is suitable for vacuum and inert atmosphere growth environment

Many single crystal materials need to be prepared in a high vacuum or inert gas environment to avoid oxidation or other chemical reactions. Tungsten is extremely thermally stable and corrosion resistant in vacuum and inert atmospheres, and will not oxidize, swell or embrittle due to changes in atmosphere. At the same time, its low vapor pressure allows it to have a very low sublimation rate under high temperature vacuum, reducing the influence of the crucible material on the crystal and furnace environment.

6. Auxiliary control of crystalline interface morphology

The wall thickness, inner diameter, bottom structure and thermal coupling relationship between tungsten crucible and heater will affect the flow and temperature field distribution of the melt, thus indirectly adjusting the shape of the crystallization interface. Through the reasonable design of the crucible structure, such as the arc transition at the bottom, the heat screen on the side wall, and the closing design at the top, the crystal can be effectively guided to grow stably in a specific direction, the crystal distortion rate and internal stress distribution can be controlled, and the quality and yield of the final crystal can be improved.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com