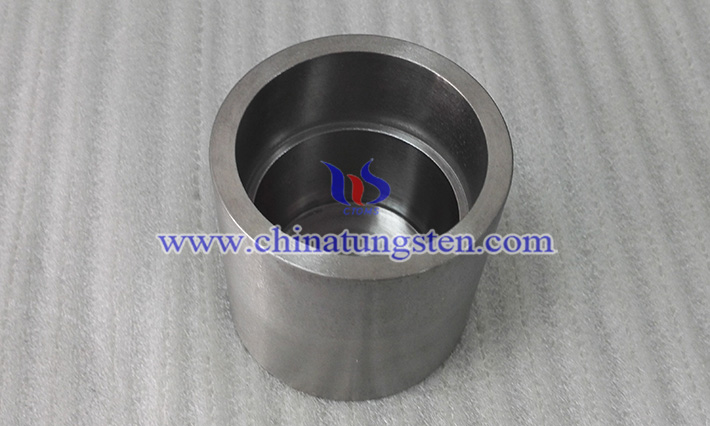

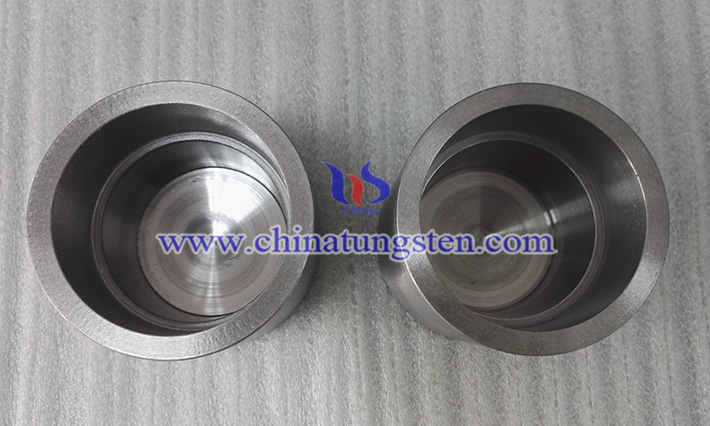

Corrosion Resistance of Tungsten Crucible and Improvement Methods

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 15:21

In some special high-temperature atmospheres or melt environments, tungsten crucibles still face a certain degree of corrosion problems. Corrosion not only affects the service life of the crucible, but can also contaminate the material being treated and reduce product quality. Therefore, improving the corrosion resistance of the crucible is the key to improving its comprehensive performance and prolonging the service life. In this paper, the corrosion mechanism, influencing factors and main improvement methods are systematically analyzed and discussed.

1. The corrosion mechanism of tungsten crucible

Although tungsten has excellent chemical stability and exhibits strong inertness at room temperature and most neutral atmospheres, corrosion reactions can occur at high temperatures, especially in the presence of oxygen, halogen gases, molten metal oxides or acidic substances. The main corrosion mechanisms include:

Oxidative corrosion: In an oxygenated environment (especially above 800°C), tungsten easily reacts with oxygen to form tungsten oxide (WO₃), which is volatile at high temperatures, resulting in the gradual consumption of crucibles;

Halogen corrosion: In halogen atmospheres containing fluorine and chlorine, tungsten may react with it to form volatile tungsten halides (such as WF₆, WCl₆), showing strong vapor phase corrosion;

Melt corrosion: Chemical or penetrant corrosion occurs when dealing with certain molten metal oxides (e.g., Al₂O₃, SiO₂, B₂O₃) or strong acidic melts, resulting in chemical or penetrant corrosion;

Galvanic corrosion: In environments with electric fields or current conduction, the surface of tungsten may be locally anodized, resulting in pitting or galvanic corrosion.

2. Factors affecting the corrosion resistance of W crucible

Material purity: Impurity elements (such as Fe, Ni, C, O) may form easily oxidized phases or promote grain boundary corrosion at high temperatures, reducing corrosion resistance;

Sintering density: crucibles with high porosity are easy for gas or melt to penetrate, resulting in accelerated corrosion diffusion;

Surface state: crucibles with large surface roughness and defects such as microcracks are more likely to become the starting point of corrosion;

Atmosphere: Oxygen, water vapor, halogen and sulfur vapor can greatly aggravate the high-temperature corrosion of tungsten;

Melt type: Acidic or strongly reducing melts are more likely to chemically react with tungsten, accelerating material loss.

3. Improvement method of corrosion resistance of W crucible

1. Surface coating treatment

Oxide coatings: ceramic coatings such as ZrO₂, Al₂O₃, Y₂O₃ and other ceramic coatings can form a stable protective film at high temperatures to block oxygen and melt;

Nitride/carbide coatings: coatings such as TiN and SiC are not only resistant to high temperatures, but also have high chemical stability, and are suitable for reducing atmospheres or halogen environments;

Coating processes: Commonly used methods include chemical vapor deposition (CVD), physical vapor deposition (PVD) and plasma spraying. Proper selection of the process ensures that the coating is firmly bonded to the substrate and is not easy to peel.

2. Alloying method

By adding a small amount of high melting point and antioxidant elements (such as molybdenum, rhenium, tantalum, hafnium, etc.) to tungsten to form tungsten-based alloys, its corrosion resistance and high-temperature mechanical properties can be improved. For example, W–Re alloys can improve the thermal stability and oxidation resistance of tungsten due to their lattice distortion effect, but the cost is higher.

3. Preparation and densification of high-purity tungsten

Improving the purity of raw tungsten powder, controlling the sintering process parameters, and using hot isostatic pressing (HIP) and other technical means can effectively reduce the porosity and impurity content of tungsten crucible, thereby significantly improving its corrosion resistance.

4. Atmosphere control and process optimization

The use of high-purity argon or vacuum can significantly reduce the risk of oxidative corrosion during crucible use. At the same time, the service life of tungsten can be extended by temperature control to prevent the surface from entering the "critical temperature zone" where it is easily reactive.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com