Tungsten Carbide Atomizing Nozzle Principle IV

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:25

According to the media, another tungsten carbide media atomizing nozzle can be specifically divided into vapor atomization, air atomization. In accordance with atomizing method can be divided into bubble atomization and pneumatic atomization. By means of fluid such as air or steam high-speed jet speed coaxial or vertical direction is atomizing liquid column or film, which also called as the two-fluid atomizing nozzle.

This kind of nozzle accelerated surrounding airflow flowing and took advantage of high-speed (normally tens of meters per second), and even ultrasonic air or steam contacted with the liquid column and film of low-speed liquid each other to vibrate, friction, finally come in to be droplets.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Mine Enterprises in Ganzhou-II

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 16:02

The technology of producing coarse, medium, fine or superfine W/WC powder and nano size W/WC powder in Chongyi Zhangyuan, Dayu Weiliang, Ganzhou Yuan-chi etc. can catch up with the most advanced level in china. Series of products are sold to European, American and Asian markets.

1,000 tons of hard facing materials invested by Chongyi Zhangyuan and American Inframat Corporation and 1 million pieces of cemented carbide tools with its own properties invested by Chongyi Zhangyuan Tungsten Co., Ltd. are in construction. The project of 3,000 tons of cemented carbide invested by Zhongrui Company, and the project of 700 tons of tungsten rods invented by Jiangxi Yaoshen are all under construction.

Tungsten industry makes great progress in recent years. Sales value in 2006 is 11.03 billion RMB, which is 14.5 times more than that in 2000. Tax income is 1.62 billion RMB, which is 36.7 times more than that in 2000. The average growth rate of sales value is 158% and tax income 184%.

We will pay much attention to economizing resources, protecting environment and developing harmoniously. And we are taking measures in protecting environment and improving the level of utilizing resources and solving the problems due to exploring.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Mine Enterprises in Ganzhou-I

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 15:58

There are 66 tungsten enterprises in Ganzhou, 19 of which are of good strength. The yearly capacity is 45,000 tons of APT, 25,000 tons of tungsten bars, 6,000 tons of W-Fe, 2 billion meters of Tungsten wire, and 3,000 tons of cemented carbide (including heavy alloy). In 2006, the shares of tungsten products in Ganzhou are Tungsten concentrate 30%, APT 65%, W-Fe 40%, W power 30%, tungsten bars 25%, tungsten wire 8% and cemented carbide 8%.

The technology of producing APT in Ganzhou is the most advanced in the world. Its technology of scheelite recovery and the mixed flotation dressing has been popularized. The technology called “Milling, ion-exchange,

continuous-crystallization” has been employed in tungsten metallurgical process in Chongyi Zhangyuan Tungsten Co. Ltd. and in APT with particle size from 1 to 50 µm and various crystal shapes could be produced. Jiangxi Tungsten Alloy Company produces W-Fe of high quality by using low-level tungsten and waste tungsten imported from abroad.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Mining in Ganzhou

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 15:55

Until the end of 2006, there are 53 Tungsten Mine Enterprises in Ganzhou. The yearly ore mining capacity is 6 million tons and ore processing capacity 5 million tons. Ganzhou has supplied about 1.2 million tons of tungsten concentrate since 1949, which is 49% of the total output in China. From 1980s, the recovery of tungsten mines has been improved a lot by importing new technologies. In 2006, the recovery value was about 1 billion RMB, which is 10% of the total value of Tungsten mine. Ecological environment in tungsten mines has been improved a lot by comprehensive treatment.

Ganzhou employs policies of mining tungsten strictly controlled by national mining quota. The output of tungsten concentrate has decreased 20% since 2000. Meanwhile, 2/3 of tungsten concentrate in China is processed in Ganzhou. 4,000 tons of tungsten raw material are supplied from abroad every year.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Resource Situation of Tungsten Mine in Ganzhou

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 15:46

Nanling Mountain and Luoxiao Mountain join up in Ganzhou. The eastern part of Nanling metallogenitic belt is in Ganzhou, which is one of the most important tungsten metallogentic belts in China. This unique and complex geological structure makes Ganzhou a famous area of tungsten resources in the world, reserves106 mining areas and more than 30%of total reserves of China.

Tungsten reserves in Ganzhou are characterized by concentrated reserves, various kings of ore deposits, high quality ore, many associated minerals. From stratigraphical analysis the average tungsten content in stratum of Ganzhou is 9.53ppm, somewhere more than 12ppm. This is more than 7 times over the world average value of 1.3 ppm. Ore deposit forms include quartz-cassiterite vein, stratiform vein ,meta-sand rock etc. Among them quartz cassiterite vein with its deposit scale and reserve volume ,is the largest one in China or even in the world .As main kind of tungsten ore , wolfamite of high quality is with high grade and easy to dress. The recovery of dressing is generally more than 85%.The associated minerals of tungsten ore deposits: tin, molybdenum, bismuth, copper, lead, zinc, silver and beryllium, niobium, tantalum, rare earth, lithium, crystal, fluorite and so on ,could be all recovered and made use of .

Based on the regularity of tungsten ore formation and special geologic structure in Ganzhou, geologists have found the so called ‘5-layer structure ’and ‘7-layer structure ’model for the vein type tungsten deposits,especially for wolframite. This means that from surface to depth of earth stratum the vein gets larger and the vein type changes in order of ‘mark belt made of super fine linear veins –fine veins belt –fine and thin veins mixed belt –thin veins belt –large veins belt’. These models have played an important role in research and development of geological survey and mining. It is forecasted that in the next 5 years the tungsten reserves newly found in Ganzhou will be 2 times of the reserves today .Tungsten resources in Ganzhou are sure to have huge potential and bright future.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Forging Process of Producing Tungsten Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 14:57

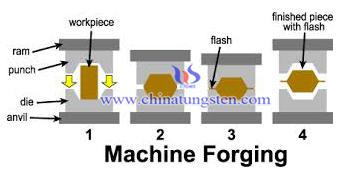

Forging is a main machining process to produce tungsten radiation shielding.Tungsten and several tungsten alloys have been successfully forged over a wide range of temperatures from as low as 1800 to 3500F. In rocket nozzle forging, a billet height reduction of approximately 80% at forging temperatures below the critical recrystallization temperature is considered essential. This imparts the fine-grained, fully wrought, fibrous structure that is characteristic of high strength and good ductility at low transition temperatures.

Tungsten is generally forged in the hot-cold work temperature range where hardness and strength increase with increasing reductions. Both systems exhibit increase forgeability with decreasing grain size. The greatest use of tungsten forgings has been in rocket nozzle applications. Production forging of tungsten nozzle inserts has been largely limited to billets prepared by powder metallurgy techniques because of their earlier availability than cast tungsten.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Polymers for Medical Devices

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 14:55

Tungsten polymers are used to produce catheters and other devices that are inserted into the body for diagnostic or interventional procedures are commonly filled with substances opaque to x-rays, thereby rendering the devices visible under fluoroscopy or x-ray imaging. These fillers, or radiopacifiers—tungsten(typically dense metal powders)—affect the energy attenuation of photons in an x-ray beam as it passes through matter, reducing the intensity of the photons by absorbing or deflecting them. Because these materials exhibit a higher attenuation coefficient than soft tissue or bone, they appear lighter on a fluoroscope or x-ray film. This visibility provides the contrast needed to accurately position the device in the affected area. Image contrast and sharpness can be varied by the type and amount of radiopacifier used, and can be tailored to the specific application of the device.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Radiation Shielding Materials Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 August 2015 18:56

A particularly dense material with excellent shielding properties is needed to ensure that the surrounding tissue is protected and the radiation guided only to the intended locations--high density tungsten alloys are widely used as medical and industrial radiation shielding applications.

Tungsten alloys are used for radioactive source containers, gamma ray protection, radiation shields, x-ray shielding and source holders for oil-well, logging, and industrial instrumentation. We can also use our tungsten alloys to make collimators and shielding for cancer therapy machines, and as syringe protection for radioactive injections.

There is no licensing required for tungsten alloy materials. Tungsten alloys are stable at high temperatures. You can use one-third less material than lead for the same energy-absorbing effectiveness, meanwhile it is non-toxic.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Extrusion Process of Tungsten Alloy Shielding

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 August 2015 18:53

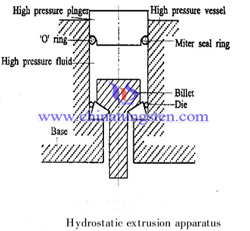

Extrusion, which is a process used to create objects of a fixed cross-sectional profile. Tungsten alloy material can be pushed or pulled through a die of the desired cross-section in extrusion process. The extrusion process may also increase the strength of tungsten alloy shielding.

The process begins by heating the stock material (for hot or warm extrusion). It is then loaded into the container under the press. A dummy block is placed behind it where the ram then presses on the material to push it out of the die. Afterward the extrusion is stretched in order to straighten it. If better properties are required then it may be heat treated. The extrusion ratio is defined as the starting cross-sectional area divided by the cross-sectional area of the final extrusion. Compared with forging, one of the main advantages of the extrusion process is that this ratio can be very large while still producing with quality. For the extrusion process, only one compression can cause extrusion ratio is about 60%~80%. In forging process, one compression cause extrusion ratio is no more than 20% ,otherwise the scrap rate will be greatly enhanced.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Something about Ammonium Paratungstate Structure from Lanthanum Tungsten Electrode Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 August 2015 18:19

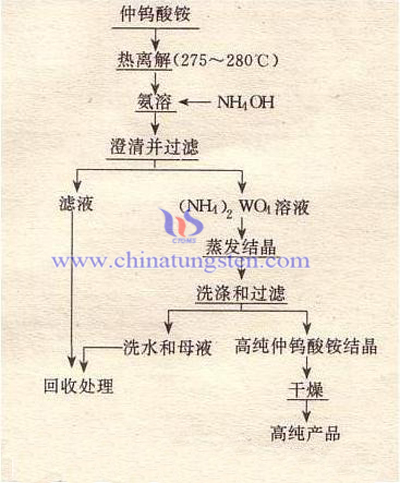

Ammonium paratungstate (APT) is one of the materials for the preparation of lanthanum tungsten electrode, which is a kind of white crystalline salt. After World War II, there are literatures showing that the anion in (NH4)10(W12O41) ·5H2O has been proved to be [H2W12O42]10−, holding two hydrogen atoms inside the cage. Tungsten-oxygen cage, the focus of the anion, requires 42 oxygen molecules. Therefore, the correct formula expression for ammonium paratungstate is (NH4)10[H2W12O42] ·4H2O. On the contrary to the paratungstate A ion, whose anion is [W7O24]6−, the paratungstate B ion is [H2W12O42]10− ion, which is similar to the paramolybdate ion. However, the existence of the paratungstate A ion can’t be confirmed by NMR (Nuclear Magnetic Resonance) spectroscopy.

Before 1930, there had been some argument about the exact composition of the salt, and someone had proposed the two structures at that time: (NH4)10W12O41 and (NH4)6W7O24. And O.W. Gibbs had said that” the alkali tungstate are unusually complex. Salts of essentially different formula is so close in composition ratio that the differences lie very near the unavoidable errors of analysis. The analysis is hardly sufficiently close to deciding the question on purely analytical grounds."

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com