Forging Process of Producing Tungsten Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 14:57

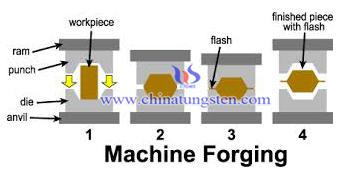

Forging is a main machining process to produce tungsten radiation shielding.Tungsten and several tungsten alloys have been successfully forged over a wide range of temperatures from as low as 1800 to 3500F. In rocket nozzle forging, a billet height reduction of approximately 80% at forging temperatures below the critical recrystallization temperature is considered essential. This imparts the fine-grained, fully wrought, fibrous structure that is characteristic of high strength and good ductility at low transition temperatures.

Tungsten is generally forged in the hot-cold work temperature range where hardness and strength increase with increasing reductions. Both systems exhibit increase forgeability with decreasing grain size. The greatest use of tungsten forgings has been in rocket nozzle applications. Production forging of tungsten nozzle inserts has been largely limited to billets prepared by powder metallurgy techniques because of their earlier availability than cast tungsten.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com