Tungsten Darts Throwing Basics

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 19:23

The throw is the most important element of a successful tungsten dart player. And yet, most players don’t analyze this critical aspect of their tungsten dart game. Most people go with what feels most comfortable without thinking about how they could be sabotaging their tungsten dart game. The next time you are shooting tungsten darts, take a closer look at how other people throw tungsten darts. Some rock back and forth, some lunging forward with every throw, some throw quickly and without a follow-through, and others balance on one foot.

Every throw is unique, but here are few things you should know before you develop your tungsten dart throw:

Proper alignment. The first step to a good throw is aligning your shoulder, elbow and hand in a straight line. All three should point at the board. Some people move their elbow slightly to the left or to the right depending on personal preference, but don’t go too far with this movement because it can develop into bad mechanics.

Steady throwing motion. The ideal throwing motion is similar to how you would swing a hammer. Using your elbow, hand, wrist for speed, your shoulder for support. As you extend your arm the elbow should rise up and create the force needed to speed the tungsten dart towards the board.

Holding the tungsten dart. Don’t hold the dart sideways at the beginning of your throw. To achieve a high level of skill at tungsten darts all non-essential motions should be minimized or avoided. Keep your tungsten darts level and pointed directly at the target.

Balanced stance. A strong center of balance is very important to the throw. Whatever you do, make sure you’re balanced when throwing. Leaning or swaying is typically a bad idea because it makes the tungsten dart board not only a small target, but a moving target.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cerium Tungsten Electrode Work Function

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 18:26

Positive ion cathode temperature is relatively low because of cerium tungsten electrodes, it is possible to make the cathode spot and the spots on the surface of the electrode region near the evaporated material in the form of referrals from easily condensed to a cathode potential minimum cathode spots. Thus, life and allow current increase in plasma cutting, water cooled anode and cathode role to play, while inhibiting the excessive evaporation and diffusion of active substance. But also it may be cerium tungsten electrode tip achieve a better balance of evaporation and condensation to form a "natural sharpening" feature. This "natural sharpening" feature enables sustained high arc stability, electrode and nozzle life expectancy. Thorium tungsten electrode work function higher than cerium tungsten electrode, the cathode pressure drop is relatively large, and the cathode spot withstand the current is large, when there is more than this cathode spots can withstand the maximum current flows cathode spot immediately He began to split. Because the cathode spot (in a molten state) is in the positive ion bombardment by the conditions of the formation, so to increase their number will make the cathode temperature rise, leading to the electrodes evaporated in serious condition, and even lead to the ends of the electrodes contraction phenomenon, and Arc will produce drift, resulting in decreased electrode life.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Arc Performance of Welding Cerium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 18:23

Cerium tungsten electrode arc performance is better (with respect to thorium tungsten electrode), this is because: With the decline in work function of cerium tungsten electrode, the cathode fall will be reduced, so that the cathode spot become smaller, and ultimately launch also be able to concentrate. As the arc current increases, the arc generated by the magnetic field with increasing pressure of the heart, and therefore, the arc will be compressed (by a large current), finally the emission current density of the cerium tungsten electrode will be improved.

When welding the work piece, at the central axis of the arc, the density of metal vapor generated when the arc heating weld pieces is the highest, and its resistance is relatively large. In addition, when the cathode voltage drop down, the cathode arc spots loss will be reduced, so that the construction arc can also be carried out at low current, and the arc is easier to stretch, which creates the conditions for the metal foil welding.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Maximum Allowable Current Experiments on Cerium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 18:16

Reverse polarity test

Experiment one

Experimental Materials: 2% Ce-W tungsten cerium electrode, 4% Ce-W cerium tungsten electrode, 2% Tn-W thorium tungsten electrode

Electrode requirements: a diameter of 5mm;

Experimental procedure: Under the condition of current = 80A, make the electrode ends flat, fixed and vertical, burn 20minute;

The results: 2% / 4% Ce-W cerium tungsten electrode is not stable at the beginning, and then it stabilizes; whereas arc of 2% Tn-W thorium tungsten electrode is always unstable.

Experiment two

Experimental materials: it is the same with the” Experiment one”

Electrode requirements: a diameter of 7mm;

Experimental procedure: Under current = 105A conditions, burning 12 minute;

Experimental results: loss of 4% Ce-W cerium tungsten electrode is the smallest one.

Positive polarity test

Experimental materials: the same with the” Experiment one”

Electrode requirements: a diameter of 5mm;

Results: Under the same conditions, the damage of the three kind of electrode, the damage of 2% Tn-W thorium tungsten electrode is most serious, while the case of 4% Ce-W cerium tungsten electrode is preferably.

Exchange experiments

Experimental materials: the same with the” Experiment one”

Electrode requirements: a diameter of 5mm;

Experimental procedure: Under the same conditions of exchange experiments;

The results: the case of 2% Ce-W cerium tungsten electrode is the best, 2% Tn-W thorium tungsten electrode followed.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

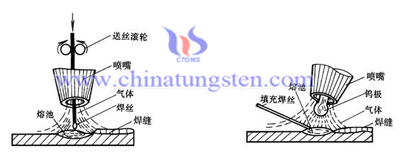

Something about TIG from Pure Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 18:14

Pure tungsten electrode is the first one kind of electrode used in TIG welding technology. TIG, whose English full name is Tungsten Inert Gas, often called non-MIG welding. TIG is a kind of gas shielded welding method, in which inert gas (argon) as a protective medium, and tungsten electrode in which is only playing a conductive role without melting, there will be arcing between them when it is energized, tungsten electrode and the workpiece. During the welding process, it can be filled with wire or without wire. If you need to fill in the wire, the wire should be filled from the front of tungsten.

TIG welding can be divided into: manual welding, automatic welding, in which manual welding of pure tungsten electrode is widely used, and in the aerospace industry, it has been used on welding high-quality work.

TIG welding technology has the following advantage: good welding quality; convenient operation of the arc and the pool (due to its good visibility); without little or no slag (because it does not using flux), and you do not need to clean up slag after welding.

Pure tungsten or activated tungsten - thorium tungsten, cerium tungsten, zirconium tungsten, lanthanum tungsten, as non-consumable electrode to shield arc, and it having high quality but its welding speed is relatively slow.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Porous Nozzle Factors II

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:39

In the beginning, tungsten carbide porous nozzle uses the impact of water-flow for rock cracking. After that it depends on the returned flow for scouring the wall and associate with jet-flow pressure, which deepens the hole and increases the volume. Some related experimental statistics show that the growth of aperture will decrease with as time goes by and every type of nozzles are similar, which explains that tungsten carbide porous nozzle aperture is determined by the diameter of hole D and less influenced by quantity of holes. In addition, with the increasing numbers of spraying holes, the roundness of hole will increase. And less holes will make flow disperse and can not connect well, which make it out of round.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Porous Nozzle Factors I

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:36

First of all, the time of erosion has an influence on the efficiency of tungsten carbide porous nozzle for drilling. Generally, if erosion time is longer, the aperture, hole depth and the broken volume will increase. However, the raising trends will be different due to various types of nozzles. As tungsten carbide porous nozzle, with time goes by, the hole depth and broken volume will increasing remarkably at the beginning and tend to gently. It is proves that the principle of water-flow for rock cracking is a dynamic process and has obvious periodicity.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Sand-blasting Nozzle III

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:32

There are two common difficulties when tungsten carbide sand-blasting is working. One is the difficult suction, the other one is about abrasion. The main reason is the size of the sand entry is too small and the vacuum is not enough. While the inside blowhole do not match the straight section mixed with sand and water or the material of straight section mixed with sand and water is inappropriate so that the nozzle is badly abrasive.

Therefore, the quality of tungsten carbide sand-blasting nozzle is determined by inhaling tube diameter, the size of blowhole, the straight sections and the materials. Controlling the distance of nozzle and steel plate is the most importance to achieve the best result. In addition, adding corrosion inhibitor will prevent the metal surface from two-stage oxidation.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Sand-blasting Nozzle II

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:30

It not only enhances the hardiness of film, but also improves mechanical and anti-fatigue performance. Regardless of inhale-type dry sand blaster, press-in dry sand blaster or fluid sand blaster, tungsten carbide nozzle is an essential part of them. The sand-blasting processing is widely used in surface derusting, which caused by electrochemical corrosion and leaves many pits on that.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Sand-blasting Nozzle I

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:28

The Sand-blasting processing uses the impact energy of high-speed sand flow and compressed air to coarsening and cleaning the surface of matrix. It consists of copper mine sand, emery and quartz sand, etc. Through impacting and cutting on the surface of work pieces by grinding compound, the surface and the shape of metal work pieces will be changed for getting roughness and cleanliness.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com