CVD Diamond Coated Carbide Pretreatment—Mechanical Process (1/2)

- Details

- Category: Tungsten Information

- Published on Monday, 25 January 2016 17:31

Traditional mechanical process refers to the treatment of the surface, such as grinding, sand blast and so on. When it used in the CVD diamond coated carbide tools, which is the main means of mechanical polishing and ultrasonic cleaning. Mainly using diamond abrasive powder or fine diamond paste on respective base body is polished such that the surface of the substrate or the surface of the large number of mechanical scratches or shallow grooves, resulting in surface defect density is increased and the expansion of diamond nucleation sites. Solid surface defect position contains a large amount of lattice edges and kinks order, with crystal particles have higher binding force, thereby reducing the diamond nucleation free energy and enhanced nucleation effect. In addition, remain on the substrate surface diamond fine powder can be used as a seed diamond nucleation, which is one of main reason that the use of this method can greatly improve the adhesion of diamond nucleation density and the surface of the substrate.

Foreign researchers related use diamond grinding wheel for tungsten carbide matrix grinding, deposits a layer of diamond film in the process of applying the transition layer the above mentioned, through the gap between detection experiments prove diamond film and the cemented carbide substrate having good adhesion. However, after the grinding process, the surface of cemented carbide leaves more scratches, shallow pit, which will make the diamond nucleation density increase by a certain degree of influence. Meanwhile, it not only causes the damage of the surface of tungsten carbide matrix, but also has worse reuse, especially for the electronics and optics products with high demand of precision has a bad influence.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Beneficiation Technology Progress after Shizhuyuan Method

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:49

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Detinning Process of APT Production- Ion Exchange

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:46

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Direct Acidifying and Recycling Ammonium Paratungstate Mother Liquor

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:43

To achieve the goal of shorten the process, reduce the cost and improve the recovery ratio of tungsten trioxide, reduce the pH of APT mother liquid by hydrochloric acid to realize W, P, as, Mo, Si, S2- separate from NH4Cl is proposed in this paper, and filtrate can be returned directly to desorption agent, adding ammonia or liquid ammonia to increase the pH, and then returned to prepare desorption agent.

Steps are as below:

1. Adjusting pH value of APT mother liquor: turn on the stirred tank under normal temperature, and add ydrochloric acid to apt crystalline mother liquor to adjust the pH value; after H2Soverflow from mother liquor aborted with dilute ammonia, stop stirring after H2S volatilized completely, and clarified for 2 hours;

2. Filter: solid-liquid separation, using the cloth filter or microfiltration; filter residue return to the main flow alone or mixed with the raw materials for alkali decomposition, and filtrate can be returned directly for formulated desorption agent or adding ammonia or liquid ammonia to increase pH and then returned to prepare desorption agent.

The advantages lie in:

1. To make full use of properties of sulfur ions, made it removed from APT in the form of H2S, and recycling as ammonium sulfide for using in recycle process, reduce the secondary pollution caused by wastewater discharge and end of pipe treatment at the same time;

2. Using hydrochloric acid to adjust pH value to make APT crystal liquor directly back to the ion exchange process of desorption agent preparation;

3. The process flow is short and simple, to realize cycle of Tungsten Hydrometallurgy, recycling WO3 and NH4Cl from crystallization mother liquor to achieve APT clean production.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ultracoarse Tungsten Powder Prepared from Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:39

The special properties of tungsten determine particle generated from tungsten oxide or ammonium paratungstate by reduction size range generally on the 2~5μm, and difficult to obtain ultracoarse tungsten powder. In this paper, the preparation technology of super coarse tungsten powder with low energy consumption, low hydrogen consumption and short reduction time was put forward using ammonium paratungstate and ammonium paratungstate as raw materials. A method that using ammonium paratungstate made from sodium tungstate and tungstate as precursor to generate ultracoarse tungsten powder with low energy and hydrogen consumption, short reduction time is proposed.

Steps are as follows:

1. Mixing solution of sodium tungstate and tungstate according to molar ratio of 1:40;

2. Heated the solution obtained in step 1 to boiling, and stop when the volume remaining 10% ~ 20%, sent to far-infrared oven for drying at 150℃ for 2 hours, then generate the precursor mixing with ammonium paratungstate and sodium tungstate crystal;

3. Sieving precursor, made the particle at 80 meshes, and then adding fine tungstate powder which take 20% of the precursor, mixed with V type mixer for 2 hours;

4. Restored in a tube reduction furnace in hydrogen; two sets of ultrasonic generator and three air hammer with uniform center spacing are set on the outer side of the furnace tube; hydrogen section flow for 0.005L/min.cm2 and the frequency of ultrasonic generator set for 25-26kHz, pneumatic hammer percussive frequency is 60 times/min, and pneumatic hammers are percussion not at the same time, time for 30min, temperature for 900℃, ultracoarse tungsten powder generated;

5. Ultracoarse tungsten powder cleaning in ultrasonic tank with deionized water, and then filtering, dehydration with industrial alcohol, drying in a vacuum drying oven in 80℃ for I~2 hours, screening, the sieved fine tungsten powder can recycling as raw material.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Effect of Tungsten Powder Granularity on Tungsten Copper Micro-structure

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:03

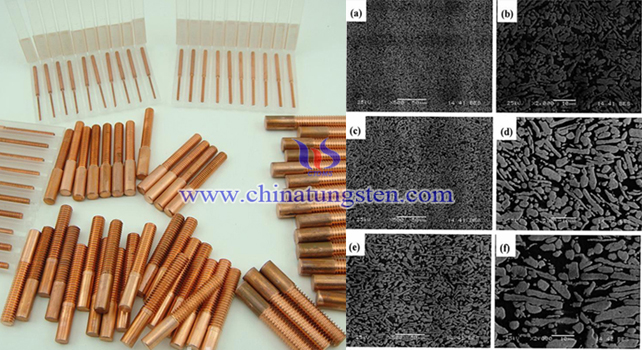

Similarly takes tungsten copper W-30Cu electrode as an example, compared with tungsten copper electrode by tungsten powder with different granularities at the same temperature SEM pictures, we can find that tungsten copper W-30Cu electrode with similar composites, the smaller the particle size of the tungsten powder, tungsten powder dispersed more evenly, but the greater the possibility of the obturator and defects, W grain size is uneven, resulting in an overall lower uniformity; on the contrary, the larger the tungsten powder particle granularity, the greater the corresponding grain size, dispersibility of the tungsten particles is reduced, the connection between the tungsten particles is weakened so that the amount of bores decreased. The following are the different particle size of tungsten powder prepared W-30Cu tungsten copper alloy electrodes SEM photograph, from left to right are the tungsten powder particle size (a) and (b) -2.9μm, (c) and (d) -4.2 -4.8μm, (e) and (f) -11-13μm:

Theoretically, the porosity of tungsten copper W-30Cu with smaller granularity is smaller than the coarser one at the same sintering temperature. This is due to in the process of sintering (surface diffusion plays an leading role at 1350℃ sintering temperature) with the decreasing granularity of powder, the free energy will increase, which further promotes the sintering processing. While interconnected particles occurs first in the surface of the particles.

The finer the grain size of tungsten powder, which means larger specific surface area, active surface atoms, the more the (surface energy increases), so that the surface diffusion easier to carry out. Reduced powder size is also thought to increase the diffusion of the interface between the particles, and to shorten the diffusion path, thus increasing the number of atoms per unit time-proliferation. In addition, the granularity too coarse to cause uneven tungsten skeleton bores and lead to the appearance of copper enrichment after the infiltration; and the particle size is too prone to particle agglomeration Details such tungsten skeleton prone channel closed or blocked, leading to infiltration of liquid copper is difficult to completely infiltrated, leaving part of the pores in the products, so that the uneven distribution of tissue composition of the product. Therefore, the granularity and the combination of the granularity has an remarkable influence on infiltration process.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

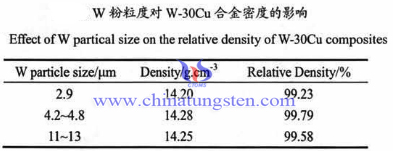

Effect of Tungsten Powder Granularity on Tungsten Copper Density

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 17:00

The granularity of tungsten powder plays an important role in the comprehensive properties, such as the hardness, the density, the electrical conductivity and micro-structure and so on. Here we are concentrated on the effect of tungsten powder granularity on the density of tungsten copper electrode.

Take W-30Cu tungsten copper electrode as an example, there is sheet of effect of the granularity of W particle on the relative density of W-30Cu tungsten copper electrode (different size, includes 2.9μm, 4.2-4.8μm and 11-13μm) as follow:

Theoretically, the granularity of tungsten powder is one of the main factors of the effect of tungsten copper electrode structure and properties. Viewed from the sheet, we can see that the experiment were used Fibonacci particle size of 2.9μm, 4.2-4.8μm and 11-13μm tungsten powder by pressing, infiltration and other technology to prepare W-30Cu tungsten copper electrodes. Several tungsten powder (W) sizes of the resulting tungsten copper alloy electrical extreme density in 14g / cm3 or more, relative density has reached more than 99%, when the tungsten powder particle size 4.2-4.8μm, the relative density of up to about 99.79%, and when the tungsten powder particle size is small about 2.9μm, relative density or lower density, relative density of about 99.13%.

Generally, the smaller granularity of tungsten powder, the smaller capillary radius and the higher liquid metal increases, it is more beneficial for the infiltration processing. However, finer tungsten powder has larger specific area and higher energy of surface, which internal close bores of the porous tungsten skeleton will increase and the liquid metal (copper, Cu) is difficult to penetrate. In addition, the finer the particle size of the tungsten powder, tungsten copper alloy tungsten particle size is smaller, the possibility of greater obturator and defects, tungsten copper electrode so that the uniformity of the overall organization is also affected. Therefore, selecting a moderate size tungsten powder is more suitable for tungsten copper alloy electrode production and processing.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Chinese Zodiac Gold-plated Tungsten Blocks

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 16:17

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Gold-plated Tungsten Birthday Block of Monkey Year

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 16:14

| Tungsten Gold Plated Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Dirty Bomb Shielding Container(2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 22 January 2016 16:12

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com