SCR Denitration Catalyst Recovers Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 17:07

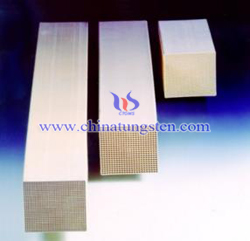

Currently, working life of SCR denitration catalyst is generally 3~5 years, the commonly treatment ways of the deactivated catalyst are regenerating or landfill. Landfill will not only result in the occupation of land resources, but also a tremendous waste of resources. According to statistics, by 2018, it will produce annually 38,000 tons of waste SCR denitration catalyst, which contains 1520 tons of tungsten trioxide. Because tungsten is a rare metal and the very high price of tungsten trioxide, if the waste SCR catalyst can’t get reasonable treatment and the valuable resources can’t be recovered, the great waste of resources will cause.

Currently, working life of SCR denitration catalyst is generally 3~5 years, the commonly treatment ways of the deactivated catalyst are regenerating or landfill. Landfill will not only result in the occupation of land resources, but also a tremendous waste of resources. According to statistics, by 2018, it will produce annually 38,000 tons of waste SCR denitration catalyst, which contains 1520 tons of tungsten trioxide. Because tungsten is a rare metal and the very high price of tungsten trioxide, if the waste SCR catalyst can’t get reasonable treatment and the valuable resources can’t be recovered, the great waste of resources will cause.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Desulfurization Catalyst Used for Preparing Superior Grade White Oil

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 17:03

White oil, alias paraffin oils, mineral oils, is the highly refined colorless oily liquid with odorless, and has excellent chemical and light stability. It is widely used in industries such as cosmetics, food, pharmaceutical, plastics, chemical fiber, machinery and light industry.

White oil, alias paraffin oils, mineral oils, is the highly refined colorless oily liquid with odorless, and has excellent chemical and light stability. It is widely used in industries such as cosmetics, food, pharmaceutical, plastics, chemical fiber, machinery and light industry.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Lanthanated Tungsten Electrode Metal Injection Molding

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 16:50

The Metal Injection Molding (MIM) of insoluble metal is mainly used for manufacturing parts with complex and small size. The metal which produced by MIM isn’t has particularly high temperature strength and fatigue performance, but it can save a high of insoluble metal machining costs to achieve a nearly net shape. Traditional tungsten electrodes were produced by sintered tungsten bar and after machining to obtain pure or rare earth tungsten electrodes. Tungsten has highest melting point in insoluble metal, so machining is difficult and the cost is high, so using MIM to produce tungsten electrodes used in lighting equipment are more and more attention and favor in manufacturers. Compared with traditional method, tungsten electrode manufactured by MIM not only has complex shape which can use in different lighting equipment, but also has good performance. Pure tungsten and doped tungsten (AKS-W) is a common anode material, and thoriated tungsten, barium tungsten, and lanthanated tungsten electrode is often used as a cathode material.

Lanthanum tungsten electrodes (W-La2O3) manufactures by MIM, and the production processes are as following:

1. The La (NO3) 3 • 6H2O was dissolved in alcohol and then mixed with tungsten powder (0.1um), in which La2O3 addition is 1.5%.

2. Place the mixture into a mixing ball mill for 24h, and then to employ drying and screening process. The milling medium is alcohol, grinding body is tungsten rod.

3. The sieved powder is baking and reduction at 600 ℃, so that La (NO3) 3 will decompose into La2O3.

4. Using paraffin-polymer binder to produce MIM feed. Determine the critical powder load in feed by torque rheometer. Since 1um tungsten powder produced feed has good flow, so the loading is used 55% of the volume fraction. Besides, the compounding temperature is 158 ℃, and roller speed is 60r / min.

5. Then after injection, degreasing and sintered will obtain lanthanated tungsten electrode.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Monkey Tungsten Gold Plated Bar

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 16:15

| Tungsten Gold Plated Supplier: Chinatungsten Online t.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Goat Tungsten Gold Plated Bar

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 16:13

| Tungsten Gold Plated Supplier: Chinatungsten Online t.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Eltra Carbon Sulfur Analyzer and Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 13:40

Eltra brand was estabilished in 1980 in German, mainly focusing on research and development of elemental analyzer. It has been extended to the oxygen nitrogen hydrogen analyzer from the beginning of carbon sulfur analyzer, which is wild about research and manufacturing of analyzer. Nowadays, Eltra has become the leader on the area of elemental analyzer, which is mainly applied in steel, mining, automotive, aviation, coal, building materials, and universities and research institutes. This brand developed a resistance furnace carbon sulfur analyzer with Siemens in 1981, which was first sold in Germany in 1984. In 1988, Eltra researched and developed induction furnace carbon sulfur analyzer, expanding the international market and improving the instruments and technology for many years.

Eltra carbon sulfur analyzer can detect the content of iron, copper, alloys, ores, cement, ceramics, carbon compounds, minerals, sand, glass and other solid materials quickly and accurately. Carbon sulfur analyzer of this brand mainly consists of 16-bit microprocessor, a separate induction furnace and four Infrared detecting pools which are used to detect high and low carbon and sulfur respectively. In the detection process, this instrument can automatically switch the low range and high range of detection. The CS-800 carbon sulfur analyzer of Eltra usually adopt tungsten granule as its flux, and it has a high sensitivity, good performance, wide measurement range, and accurate analysis results, etc. There is a more special characteristic, when the detection analysis, the instrument can display its working status real time to ensure the analysis can be done simply and reliably. In addition, detection time of this type of carbon sulfur analyzer is only 40-50 seconds, which costs less time to finish the determination, and it generally use magnesium perchlorate and alkali asbestos as chemical reagent.

ELTRA is one of the world's leading manufacturers of elemental analyzers for rapid and accurate analysis of solid materials. The carbon / sulfur analyzer CS-800 is equipped with up to four independent infrared (IR) cells which allow for precise simultaneous analysis of high and low carbon and sulfur concentrations in one measurement. The sensitivity of the cells can be customized individually by selecting the length of the IR path to ensure the optimum measuring properties for each application.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Labfit Carbon Sulfur Analyzer and Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Monday, 16 May 2016 13:37

Labfit brand was established in 1992, which is an Australian-owned manufacturer of commercial grade laboratory equipment in the soil testing and carbon sulphur analysis industry. Labfit carbon sulfur analyzer is a famous Australian brand, which has many excellent technical staff that has rich experiences with solid theoretical foundation in Australia, won the trust and praise of majority of users. It possesses advanced analysis, testing, testing equipment, the main application areas include petroleum, coal, materials, universities, chemical, metallurgy, environmental protection, food and agriculture and others.

Its CS1232 infrared carbon sulfur analyzer enjoys a great popularity in the world. The type of Labfit carbon sulfur analyzer uses the latest solid-state infrared absorption detection technology with high measurement accuracy. The application of vertical furnace, make the temperature can be controlled at the set value of 1%, which can reduce the chances of rupturing of a ceramic tube. Its user interface is intuitive and easy to be understood. When the analysis of the measurement, the measuring system will automatically select the appropriate sulfur measurement unit by using the 48-bit sample injector.

Width of CS1232 infrared carbon sulfur analyzer is 76 cm, its depth is 66 cm with a height of 93 cm. It weighs about 90 kg. The detection method is using a solid-state infrared absorption. Vertical resistance furnace, using a cylindrical silicon carbide to heat elements, in order to ensure uniform temperature distribution. Use two magnesium perchlorates as drying tower, and adopt a glass wool as a filter. The carrier gas is 99.5% of pure oxygen, pneumatic gas is dry and clean compressed air, the flow of oxygen should be controlled at 3l per minute. Double purification system is used to prevent gas from entering inside the combustion tube, avoiding unnecessary industrial accidents. Using a non-porous ceramic crucible, tungsten granule is the main flux. Analyzed data including time / date, name of samples, description, number of samples, weight of samples, dial number, analyzing data, analyzing curve, analyzing time, and other standard values. However, the analysis would take long time to finish the determination, which requires 60-180 seconds. It is easy to operate air filter dust collectors and centrifugal sampling tube whose material is very strong, and it can withstand daily use. It is portable equipment with a simple appearance, with a simple keyboard to input flow calibration value.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

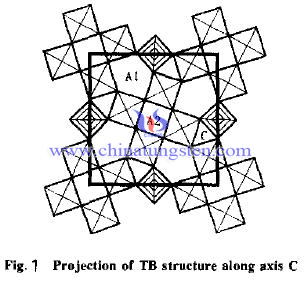

Annealing Effect on Tungsten Bronze Niobate Structure

- Details

- Category: Tungsten Information

- Published on Friday, 13 May 2016 17:54

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Gamma Ray Shielding

- Details

- Category: Tungsten Information

- Published on Friday, 13 May 2016 17:53

Gamma ray, also denoted as the lower-case Greek letter γ, is extremely high-frequency electromagnetic radiation that consists of high-energy photons. It is produced from a process called gamma decay in which an atomic nucleus decays from a high energy state to a lower energy state. Gamma rays typically have frequencies above 10 exahertz, and thus have energies above 100 keV and wavelengths less than 10 picometers, which is less than the diameter of an atom. However, this is not a strict definition, but rather only a rule-of-thumb description for natural processes. Electromagnetic radiation from radioactive decay of atomic nuclei is referred to as "gamma rays" no matter its energy, so that there is no lower limit to gamma energy derived from radioactive decay. This radiation commonly has energy of a few hundred keV, and almost always less than 10 MeV.

Gamma ray, also denoted as the lower-case Greek letter γ, is extremely high-frequency electromagnetic radiation that consists of high-energy photons. It is produced from a process called gamma decay in which an atomic nucleus decays from a high energy state to a lower energy state. Gamma rays typically have frequencies above 10 exahertz, and thus have energies above 100 keV and wavelengths less than 10 picometers, which is less than the diameter of an atom. However, this is not a strict definition, but rather only a rule-of-thumb description for natural processes. Electromagnetic radiation from radioactive decay of atomic nuclei is referred to as "gamma rays" no matter its energy, so that there is no lower limit to gamma energy derived from radioactive decay. This radiation commonly has energy of a few hundred keV, and almost always less than 10 MeV.

Gamma-ray has wavelengths shorter than X-ray, so it has more strong penetrating power than X-ray. In addition, the high-energy gamma ray is an ionizing radiation, which can cause harm to humans. When the body is subjected to 200 to 600rem doses of γ-ray radiation, hematopoietic organs of the body (such as bone marrow) will be damaged, and the rays can cause the loss of white blood cells, bleeding, hair loss, and the probability of death within two months ranges from 0 to 80%; when the radiation doses are in the scope of the 600-1000rem, the probability of death within two months ranges from 80-100%; when the scope of radiation doses changes to 1000-1500rem, the human gastrointestinal system will be destroyed, accompanying some symptoms such as diarrhea, fever, endocrine disorders, and the probability of dying within two weeks almost 100%; when the radiation doses up to 5,000rem or more, can cause central nervous system damage, spasm, tremor, disorders, narcolepsy, and the probability of death within two days is 100%.

Tungsten alloy gamma ray shielding has strong ability of gamma-ray linear attenuation, so it is an ideal γ-ray shielding material. Compared with conventional shielding materials, tungsten alloy shielding reflects good value. Lead was early used as shielding material, but in the use process discovered, its radiation shielding performance is not high enough, and it can also cause serious pollution to the environment. While under the conditions of the same thickness, the radiation shielding capability of tungsten alloy shielding is twice than the lead shielding. Moreover, tungsten alloy shielding does not produce harmful substances, so do not worry that it will cause harm to human health.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Application in " the Palm of Death" --- Grenade

- Details

- Category: Tungsten Information

- Published on Friday, 13 May 2016 17:04

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com