Notes on Good Riveting -- Bench Riveting

- Details

- Category: Tungsten Information

- Published on Thursday, 04 December 2014 08:54

- Written by Sherry

- Hits: 597

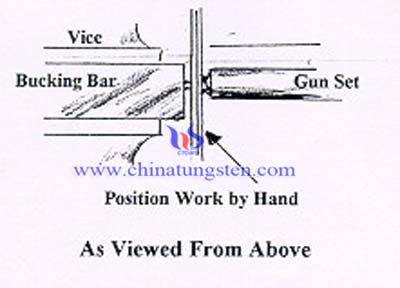

Often components are more easily riveted as sub-assemblies (off the airframe). A workbench allows components to be positioned and secured optimally for joining.

The bucking bar may be secured in a bench vice and, with the components positioned by hand, rivets are set with a gun held in the other hand. The main advantage here is that the bar is stationary and the components may be more easily held and positioned for riveting.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Bucking Bar Orientation

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 December 2014 09:12

- Written by Sherry

- Hits: 569

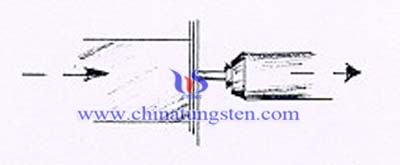

1. Rest bucking bar on inserted rivet and try to locate its point of balance.

2. With gun set in place, use bucking bar to push rivet (and gun assembly) outward. Bucking bar will then register at right angles to the rivet as it comes to rest on the aluminium.

3. Push rivet back into place with gun set and reposition bucking bar, if necessary, to maintain its point of balance on the rivet. (repeat steps 2 and 3 until point of balance is determined). Often the index finger can be placed on the back of the bucking bar directly opposite the rivet tail. It then becomes the 'sensor' for correct bar position.

4. Pressure is held on gun while riveting. Bucking bar is held with only moderate force (otherwise rivet may be set with head proud of surface). A rubber grommet may be used over the rivet tail to assist in squeezing parts together during riveting. It acts as a 'pressure plate'

5. Duration of riveting is determined by experimentation with a test piece or previous experience.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- Rivet Gun

- Details

- Category: Tungsten Information

- Published on Monday, 01 December 2014 09:30

- Written by Sherry

- Hits: 547

Rivet gun should be lightly oiled (air port and inner shank of set) daily before work commences. Set should be securely attached with retaining spring in place. It should then be tested on a firmly secured piece of wood. This will confirm its operational status and will alert the operator to any alterations necessary (change in air pressure; wrong size set, etc).

A rivet gun should not be fired:

1)Without a set secured by a retaining spring.

2)Without an intended target firmly in place against set and without ear and eye protection.

A rivet gun should be disconnected from the air source when:

1)Sets are being changed

2)Maintenance is being carried out on gun

3)Gun is not being used

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- Gun set

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 December 2014 08:59

- Written by Sherry

- Hits: 535

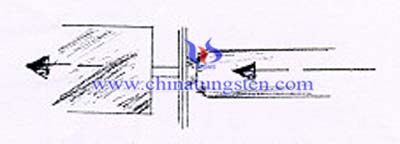

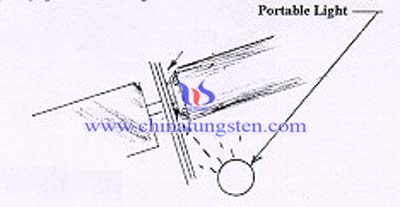

Rivet gun set is correct for the size of the rivet and is positioned at 90 degrees to the work surface. With universal rivet sets, the reflection of the gun set in an aluminium surface will give the impression of a continuous straight line with the gun set itself if positioned at 90 degrees.

Also, light reflecting from the edge of the rivet head will appear as an even line around a properly positioned gun set.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- Tips

- Details

- Category: Tungsten Information

- Published on Friday, 28 November 2014 08:49

- Written by Sherry

- Hits: 608

Tips:

Before beginning a new phase, try rigging a test piece or a component mock up. Cardboard mock ups will conserve material and will help to obtain correct sizes and shapes.

Setting the first rivets of the day should be done on a test piece to ensure proper air pressure; tool adjustment; and operator currency.

Place masking tape on rivet sets to stabilise them while riveting. (renew frequently)

A rubber grommet placed over the rivet tail will compress components together ensuring a close joint as riveting progresses. Use where clamps or clecoes are impractical.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com