Properties of Tungsten Bucking Bar-1

- Details

- Category: Tungsten Information

- Published on Thursday, 18 December 2014 09:30

- Written by Sherry

- Hits: 600

A bucking bar is a tool that is placed on a work surface or the backside of a metal rivet to provide a cushioning counter in order to hammer rivets on the opposite side. It can also be used in operations that require impact fasteners. This includes applications involving tool heads and handle parts that have low recoil absorbing space. The bar size and weight usually depends on the alloy used and the rivet size required.

In everyday use, bucking bars undergo considerable stress. The bars are meant to withstand the impact when rivet guns deliver their impulsive blow. If the supporting metal alloy is rather soft, the bucking bar will quickly wear out and the necessary assembly support will not be achieved. On the flip side, if the metal alloy is very hard and brittle, the bucking bar will soon get fractured. Striking a balance between the tendency to crack and overall hardness is vital for success.

Recent research results indicate that bucking bars made of tungsten provide extra safety for operators through vibration reduction. Operators also get less fatigued and their chances of injury are significantly reduced. The density of tungsten is a reliable property that makes it ideal for future designs of bucking bars. Most bucking bar designs contain 90% tungsten. Deburred edges and polished working surfaces ensure trouble-free use.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Bucking Bar -- Why Use Tungsten?

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 December 2014 09:04

- Written by Sherry

- Hits: 558

Many companies use steel in the manufacture of their bucking bars, but often this material does not sufficiently absorb the force or deaden the vibration and there is a still a risk to the user.

Tungsten alloy can be used in the manufacture of either the entire bucking bar or just the impact face, and is a much safer alternative than other materials. As tungsten is a very dense metal, a larger mass can be incorporated into a smaller area. The resultant extra weight is pivotal in decreasing the vibration felt by the worker.

Using tungsten bucking bars has been shown to visibly reduce the effects of vibration white finger, and consequently improves efficiency in the workplace. Studies have indicated that using Wolfmet can save workers up to three seconds per rivet.

Tungsten alloy can also be used for other tooling applications such as boring bars for machine tools and grinding quills.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

What is Bucking Bar?

- Details

- Category: Tungsten Information

- Published on Monday, 15 December 2014 09:34

- Written by Sherry

- Hits: 583

Bucking bar is a work tool received behind work surfaces to provide a backing member in applying impact fasteners and including intermitted toolhead and handle parts with a low-recoil impact-absorbing spacer provided there between to take shock loads in compression and shear.

Bucking bars are used on the backside of a metal rivet to counter the force of the hammering on the other side. They also can be used to absorb the force of rivet guns, reducing the vibration of bucking.

Bucking bars used to form bucktails on rivets. And come in many different shapes and sizes. They are normally made from an alloy steel similar to tool steel. The particular shape to be used depends upon the location and accessibility of the rivet to be driven.

The size and weight of the bar depend on the size and alloy of the rivet to be driven. Under certain circumstances, and for specific rivet installations, specially designed bucking bars are manufactured locally.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Bucking Bars

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 December 2014 09:03

- Written by Sherry

- Hits: 606

Tungsten bucking bars are included in powerful tools such as riveting guns in order to reduce vibration.

Employees using this equipment can suffer from industrial diseases such as vibration white finger and carpal tunnel syndrome. These conditions affect the bones, muscles and nerves in the hands, potentially leaving staff unable to work.

Therefore, these bucking bars can play a vital role in maintaining staff wellbeing, as well as preventing your company from having to deal with potentially costly compensation claims from injured workers.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Notes on Good Riveting -- The Grommet Trick

- Details

- Category: Tungsten Information

- Published on Friday, 12 December 2014 08:59

- Written by Sherry

- Hits: 564

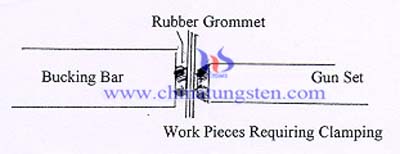

A hard rubber grommet is placed over the buck tail of the rivet. The grommet should be slightly thicker than the length of the buck tail. As the bucking bar is compressed against the tail during riveting the rubber squeezes the components together until the rivet expands enough to secure them permanently. This is a useful technique when clecoes or clamps are impractical.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com