High Performance Tungsten Oxide Preparation by Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 22:59

- Written by meiwei

- Hits: 1716

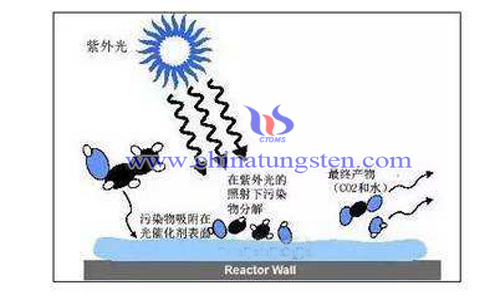

In recent years, with the development of industrialization and the rapid improvement of people's living standards, environmental pollution has become the main problem facing human beings, especially water pollution, which has attracted more and more attention. Industrial waste water accounts for a large part of the water pollution sources. Because of its dark color and strong toxicity, it is difficult to treat.

Read more: High Performance Tungsten Oxide Preparation by Photocatalyst

One Step Reduction of Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 22:54

- Written by meiwei

- Hits: 1702

To produce tungsten powder from ammonium paratungstate, it is usually necessary to first burn tungsten oxide in a weak reducing atmosphere, and then carry out hydrogen reduction to produce tungsten powder. Most of the tungsten powders prepared by this process are very regular polycrystalline, which are the main raw materials for the preparation of tungsten alloy and tungsten carbide.

Tungsten Carbide Powder Prepared from Violet Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Thursday, 07 November 2019 19:37

- Written by Yanqiu

- Hits: 1653

With high chemical activity and hydrogen reduction rate, violet tungsten oxide has become a significant raw material for preparing tungsten carbide powder. High-quality tungsten carbide powder is usually prepared by carbonization of ultra-fine tungsten powder, which is obtained from violet tungsten oxide.

Read more: Tungsten Carbide Powder Prepared from Violet Tungsten Oxide

Preparing Tungsten Carbide Powder from Violet Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Thursday, 07 November 2019 19:40

- Written by Yanqiu

- Hits: 1705

Violet tungsten oxide with good reducibility and high hydrogen reduction rate is used to prepare ultrafine tungsten powder, so as to obtain high-quality tungsten carbide powder. Carbonization is an extremely important procedure in the preparation process.

Read more: Preparing Tungsten Carbide Powder from Violet Tungsten Oxide

Preparing Tungsten Powder from Violet Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Thursday, 07 November 2019 19:34

- Written by Yanqiu

- Hits: 1734

Violet tungsten powder with unique needle structure and high chemical activity is an important raw material for the preparation of ultrafine tungsten powder. The preparation process with violet tungsten oxide is usually fast.

Read more: Preparing Tungsten Powder from Violet Tungsten Oxide

sales@chinatungsten.com

sales@chinatungsten.com