Tungsten Needle Applied for Medical High-frequency Electric Knife

- Details

- Category: Tungsten Information

- Published on Sunday, 29 March 2020 17:26

- Written by Yahong

- Hits: 2192

Tungsten needle is an environmentally friendly and non-toxic consumable on medical high-frequency electric knife. The high-frequency current generated by the electric knife is used to cut and coagulate human tissues. Specifically, the high-frequency current forms high temperature, thermal energy, and discharge at the tip of the tungsten needle of the electric knife, which quickly dehydrates, decomposes, evaporates, and coagulates the blood of the contacted tissue to achieve the function of decomposing the tissue and clotting, thereby achieving the purpose of cutting and stopping bleeding. This tungsten needle electrode high-frequency electric knife is suitable for various types of surgical operating rooms such as orthopedics, pediatrics, cardiothoracic surgery, neurosurgery, and urology.

Read more: Tungsten Needle Applied for Medical High-frequency Electric Knife

Tungsten Needle Applied for High Frequency Electric Knife

- Details

- Category: Tungsten Information

- Published on Sunday, 29 March 2020 17:24

- Written by Yahong

- Hits: 1785

Tungsten needle is a consumable of high frequency electric knife. Tungsten needle has an ultra-sharp needle point for precise cutting. Also, it has high melting point to withstand high temperatures above 3000 °C. So, such an electric knife is suitable for plastic surgery, neurosurgery, oral surgery, pediatric surgery, cardiothoracic surgery, and many other minimally invasive surgery. And the patients will recover relatively quickly as surgical wound is small.

Read more: Tungsten Needle Applied for High Frequency Electric Knife

How to Prepare Tungsten Needle?

- Details

- Category: Tungsten Information

- Published on Sunday, 29 March 2020 17:20

- Written by Yahong

- Hits: 1937

How to prepare tungsten needle? You should prepare the following materials at first:

Preparation of Tungsten Needle by Electrolytic Method

- Details

- Category: Tungsten Information

- Published on Sunday, 29 March 2020 17:22

- Written by Yahong

- Hits: 2219

How to prepare tungsten needle by electrolytic method? The following materials are needed:

Read more: Preparation of Tungsten Needle by Electrolytic Method

Ultrathin Tungsten Needle

- Details

- Category: Tungsten Information

- Published on Sunday, 29 March 2020 17:17

- Written by Yahong

- Hits: 1701

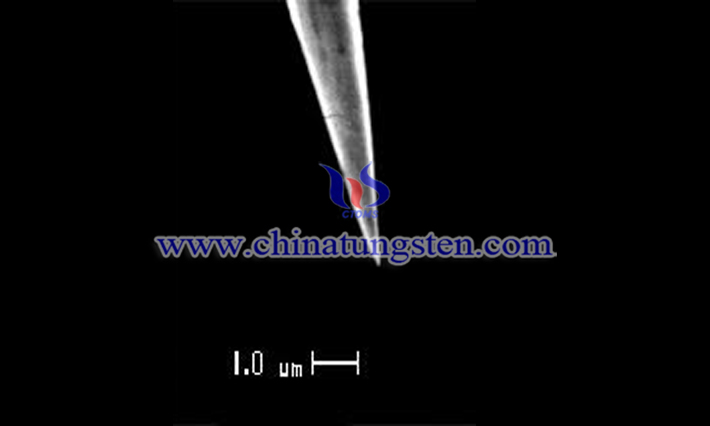

Ultrathin tungsten needle has advantages of high hardness and strong ductility. Also, it is not easy to break with durability. The diameter of tip of tungsten needle can reach micron level, which can be used to dissect and separate individual human cells, such as inner ear labyrinth cells. Some experts use 0.32mm tungsten wire to prepare ultrathin tungsten needles. They pre-machined the tips of fine tungsten wire blanks into needle-shaped, sickle-shaped, or hook-shaped needles. The diameter of the tip of these tungsten needles is generally 3 to 10 μm, and the smallest diameter can reach 1.5 μm.

sales@chinatungsten.com

sales@chinatungsten.com