Toshiba Is Developing an Ultra-fast Charging Lithium-ion Battery Using Purple Tungsten Oxide

- Details

- Category: Tungsten's News

- Published on Monday, 16 July 2018 18:42

At the just-ended Automotive Engineering Exhibition Yokohama 2018, Toshiba Materials exhibited an ultra-fast charging lithium-ion battery with a negative electrode material using purple tungsten oxide. Applications of the battery range from automotive, elevators, micro/mild hybrid vehicles, trains, uninterruptible power supplies (UPS), large current sources, to power supply stabilizer. It has an excellent and broad application prospects. As a leader in the field of lithium-ion battery technology, It is likely that Toshiba could probably put this new material into commercial use, which may further expand the demand for tungsten oxide.

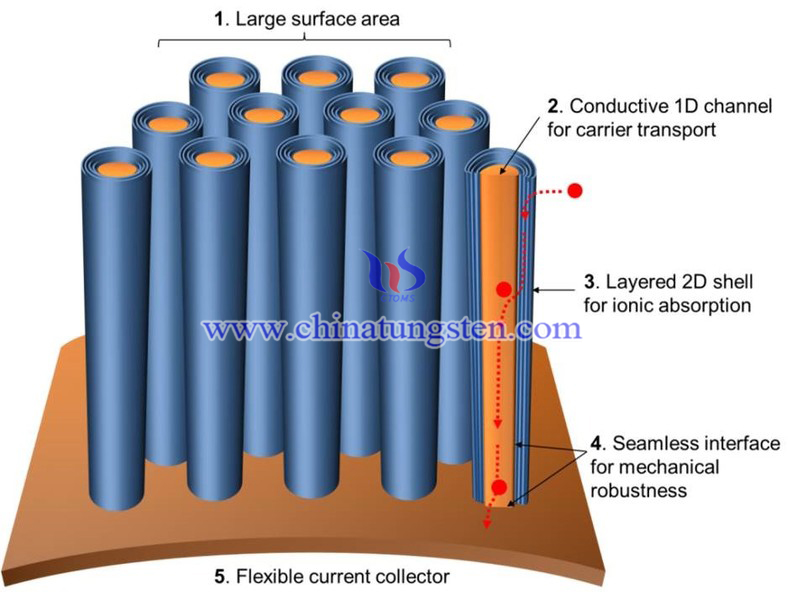

Tungsten Oxide Nanowire Supercapacitors as a Great Alternative to Lithium-ion Battery

- Details

- Category: Tungsten's News

- Published on Monday, 16 July 2018 17:47

A lithium-ion battery or Li-ion battery is a type of rechargeable battery in which lithium ions move from the negative electrode to the positive electrode during discharge and back when charging. With the development of technology, the application of lithium-ion batteries are everywhere in our lives, such as smart phones, tablets, laptops, game controllers, cordless power tools, beauty products, digital cameras, video cameras, cars, etc.

Weakness in Demand Lowers Tungsten Transaction Prices

- Details

- Category: Tungsten's News

- Published on Monday, 16 July 2018 16:49

Analysis of latest tungsten market from ChinaTungsten Online

Chinese tungsten prices continue to be unchanged on deadlocked supply and demand, uncertain fundamental and macroscopic sides. Unusually quiet trading activity in tungsten market appears to press prices down. At present, weakness in terminal demand affects the market greatly, further lowering transaction prices. In the short term, tungsten price changes slightly.

Rare Earth Price - Jul. 16, 2018

- Details

- Category: Tungsten's News

- Published on Monday, 16 July 2018 16:47

Rare earth market quotation in China: domestic rare earth price maintains stability earlier in this week. Although sellers have strong rised mentality, market prices are hard to rise in the short term without supports from the supply and policy side. At present, the off season and Sino-US trade friction make traders deadlocked in trading.

Chinese Molybdenum Price - Jul. 16, 2018

- Details

- Category: Tungsten's News

- Published on Monday, 16 July 2018 16:45

Opening this week, Chinese molybdenum price is unchanged from last week owing to increasing stop production in mines in major molybdenum production areas.

Weak Consumption for Tungsten Primary Products in China

- Details

- Category: Tungsten's News

- Published on Friday, 06 July 2018 14:32

Analysis of latest tungsten market from ChinaTungsten Online

Trading in the raw material market continues to be thin and thus consumption for tungsten primary products is weak. Before the release of guide prices from large tungsten enterprises and institutions, businesses are generally negative about the outlook.

Chinese Rare Earth Price - Jul. 06, 2018

- Details

- Category: Tungsten's News

- Published on Friday, 06 July 2018 14:30

Chinese rare earth price remains weak adjustment this week because rigid demand fails to meet market expectation and sellers do not benefit from purchasing and storage policy.

Molybdenum Price in China - Jul. 06, 2018

- Details

- Category: Tungsten's News

- Published on Friday, 06 July 2018 14:26

Molybdenum price in China is unchanged from the previous trading day as trading activity remains quiet in the market. Although operating rate increases, enterprises’ consumption for molybdenum raw materials is low. With the stabilization of international molybdenum prices, Chinese insiders hold different views on the outlook. In the short term, molybdenum price will still be stable.

Lower Guide Prices Dragged Down Chinese Tungsten Prices

- Details

- Category: Tungsten's News

- Published on Thursday, 05 July 2018 10:22

Analysis of latest tungsten market from Chinatungsten Online

Xiamen Tungsten, a Chinese tungsten enterprise, released its first guide prices in July. APT was quoted at $304.2/mtu, a $3.5/mtu lower compared with last time.

Rare Earth Price in China - Jul. 05, 2018

- Details

- Category: Tungsten's News

- Published on Thursday, 05 July 2018 10:19

Rare earth price in China maintains stability on whole while enterprises lower offer levels to move materials in some regions. With production capacity recovering gradually, pressure for supply side comes again, plus limited consumption in the off season, the whole trading is thin. In the short term, rare earth price is likely to be adjusted in a narrow range.

sales@chinatungsten.com

sales@chinatungsten.com