Europium Oxide Price - Jul. 24, 2018

- Details

- Category: Tungsten's News

- Published on Tuesday, 24 July 2018 16:01

The latest price of europium oxide, praseodymium oxide and praseodymium neodymium oxide is unchanged from the previous trading day. State Reserves Bureau held the conference concerned with rare earth reserves last week, raising sellers’ wait-and-see mentality.

Chinese Molybdenum Prices - Jul. 24, 2018

- Details

- Category: Tungsten's News

- Published on Tuesday, 24 July 2018 15:59

Chinese molybdenum prices are stable with good momentum as sellers in raw materials have strong rised mentality and new round of steel biddings perform well.

China Tungsten Prices Went Down Slowly Last Week on Weak Market

- Details

- Category: Tungsten's News

- Published on Monday, 23 July 2018 17:29

Analysis of latest tungsten market from ChinaTungsten Online

APT guide prices for late July were released by large tungsten enterprises last week, which were adjusted according to Chinese tungsten market. An enterprise in Fujian, China quoted at $300.7 per tonne and $295.5 per tonne in Jiangxi. Besides, sales of goods were thin and transaction prices lowered than before. Taken together, tungsten prices in China were in a downward trend last week.

Chinese Rare Earth Price - Jul. 23, 2018

- Details

- Category: Tungsten's News

- Published on Monday, 23 July 2018 17:26

Chinese rare earth price continues to be in a stalemate. On the one hand, weak demand and relatively adequate stocks cool trading activity and buyers try to force prices down; on the other hand, purchasing and storage of rare earth was not stated clearly at the conference and thus market participants becomes more cautious on trading. Taken together, short-term rare earth price will stabilize.

Molybdenum Powder Price - Jul. 23, 2018

- Details

- Category: Tungsten's News

- Published on Monday, 23 July 2018 17:23

Opening this week, prices of ferromolybdenum, molybdenum concentrate and molybdenum oxide rise slightly while molybdenum powder price maintains stability.

Tungsten Powder Enterprises Are Reluctant to Trade in a Weakening Market

- Details

- Category: Tungsten's News

- Published on Friday, 20 July 2018 15:43

Analysis of latest tungsten market from ChinaTungsten Online

Low trading activity in tungsten concentrate market is pressing down tungsten product prices as well as psychological prices of buyers. It is hard to do the sales in the market when the tax policy was canceled. 65% wolframite concentrate was quoted at $16,461.5-16,769.2/t and 65% scheelite concentrate was quoted at $16,307.7-16,615.4/t.

Chinese Rare Earth Price - Jul. 20, 2018

- Details

- Category: Tungsten's News

- Published on Friday, 20 July 2018 15:33

Chinese rare earth price remains weak adjustment this week due to the Sino-us trade war and quiet policy for purchasing and storage. The environmental protection inspection was finished and operating rate of manufacturers rises, but under the weakening market, rare earth prices are under pressure, with limited space of adjustment. In the short term, market participants mainly wait and see.

Molybdenum Powder Price - Jul. 20, 2018

- Details

- Category: Tungsten's News

- Published on Friday, 20 July 2018 15:29

The latest price of molybdenum concentrate, molybdenum powder remains unchanged from previous trading day while molybdenum oxide price rises slightly. Most businesses are optimistic about the market and reluctant to sell for higher prices as mines in major molybdenum production areas stop production to undergo repair.

The Titanium Dioxide-Tungsten Trioxide Nanocomposite Film

- Details

- Category: Tungsten's News

- Published on Wednesday, 18 July 2018 18:23

Typical metal oxides in semiconductors such as titanium dioxide and tungsten trioxide, have the advantages of low cost and good availability, toxic free and safe, stable biochemical properties, and resistant to light corrosion, and have become the most widely studied and widely used metal oxides.

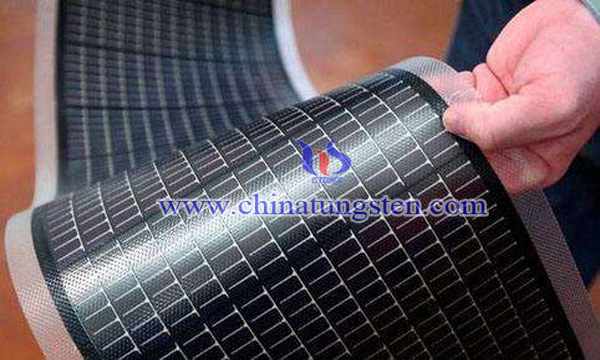

New Nanomaterial that Makes Graphene Solar Cell Feasible

- Details

- Category: Tungsten's News

- Published on Wednesday, 18 July 2018 17:22

Graphene is a single layer of carbon atoms and has desirable properties for a variety of applications. In the past decade, graphene is the most popular material. In 2017 alone, more than 30,000 research papers on graphene were published worldwide. For example, the most anticipated graphene solar cells. The most advantage of graphene as a material for batteries is that the conduction is extremely fast. But it has some disadvantages that limit its application to graohene solar cells. Happily, scientists had create a new nanomaterial contains graphene that makes graphene solar cells feasible.

sales@chinatungsten.com

sales@chinatungsten.com