Bucking Bar and Rivet

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 15:04

- Hits: 1883

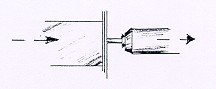

Although the use of composite materials is increasing in the manufacturing of aircraft, manual

riveting operations are still very pervasive in the assembly of aircraft. Riveting operations in aircraft manufacturing involves the use of power tools for manually drilling and countersinking holes for the rivets, as well as the use of air hammers or rivet guns to drive and set the rivets. Additionally, to close the rivet, the rivet is driven against a metallic bar commonly called a “bucking bar”. The bucking bars are typically held manually, and must be held firmly to increase the quality of the riveting, as well as keep the bucking bar from “dancing” against the metal piece being riveted.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

Ergonomic Field Assessment of Tungsten Bucking Bars During Riveting Tasks

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 14:57

- Hits: 1894

Riveting tasks in aircraft manufacturing results in exposure to vibration from both rivet guns and bucking bars. Long term exposure to vibration has been associated with symptoms of vibration white finger and musculoskeletal disorders. Four different bucking bars of the same shape but different material and mass characteristics (90%tungsten, >90% tungsten, cold rolled and stainless steel) were investigated for vibration and grip muscle activity during a riveting task. The >90% and 90% tungsten bars (3.4m/s and 3.6 m/s2, respectively) resulted in significantly less mean resultant weighted acceleration when compared to the cold rolled and stainless steel (5.3 m/s2 and 5.6m/s2, respectively), whereas there was no difference in mean hand grip flexor or extensor muscle activity. These results suggest that for bucking tasks that allow access for the bucking bar size investigated, use of heavier but same sized tungsten bucking bars can reduce vibration transmission to the hand.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

Tungsten Bucking Bar and Steel Bucking Bar

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 14:52

- Hits: 1805

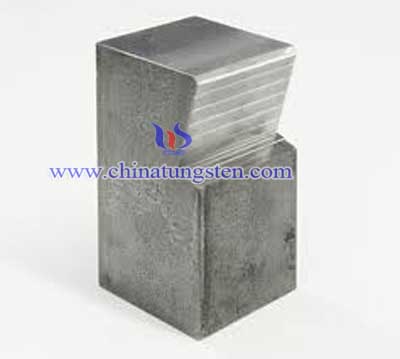

Tungsten bucking bars are the bars to call on when space is limited! Almost twice as heavy as conventional steel bucking bars of the same size.In addition to use in tight areas, Tungsten bucking bars also significantly reduce vibration and greatly improve operator comfort. Tungsten bucking bars cost significantly more than standard steel bars but once you have used one, you will never regret your purchase. One tungsten bucking bar can take the place of many conventional steel bucking bars.

All surfaces are polished to permit bucking on any side of the bar and all corners are radiused to prevent material damage.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

Bucking Bar Orientation

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 14:02

- Hits: 1712

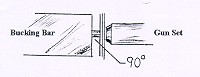

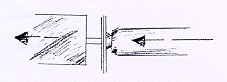

1. Rest bucking bar on inserted rivet and try to locate its point of balance.

2. With gun set in place, use bucking bar to push rivet (and gun assembly) outward. Bucking bar will then register at right angles to the rivet as it comes to rest on the aluminium.

3. Push rivet back into place with gun set and reposition bucking bar, if necessary, to maintain its point of balance on the rivet. (repeat steps 2 and 3 until point of balance is determined). Often the index finger can be placed on the back of the bucking bar directly opposite the rivet tail. It then becomes the 'sensor' for correct bar position.

4. Pressure is held on gun while riveting. Bucking bar is held with only moderate force (otherwise rivet may be set with head proud of surface). A rubber grommet may be used over the rivet tail to assist in squeezing parts together during riveting. It acts as a 'pressure plate'

5. Duration of riveting is determined by experimentation with a test piece or previous experience.

Tungsten Bucking Bar Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

HNWL Tungsten Rhenium Thermocouples Use and Type Description

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 13:55

- Hits: 1897

HNWL tungsten rhenium thermocouple is a thermocouple with superior high temperature , long-term use at 2000 degrees measurement occasions , the measurement temperature up to 2800 degrees, the highest temperature thermocouple to measure the product 's products , tungsten rhenium thermocouples very high thermal stability , with a special coat protective tube can also have long-term oxidation at 1600 degrees occasions substance use , can replace the platinum-rhodium thermocouple as metallurgy , building materials , aerospace, nuclear industry, the temperature of the measurement products.

HNWL Tungsten Rhenium Thermocouples Use :

Current measuring a temperature above 1600 ℃ , the use of non- contact method , however, the method of error is large , such as the contact law can accurately measure the real temperature . In the high-temperature thermocouples , precious metal thermocouples are expensive and the maximum temperature only in 1800 ℃ below, while tungsten rhenium thermocouple temperature limit is not only high, but good stability, therefore , tungsten rhenium thermocouples in metallurgy , building materials, aerospace , aviation and nuclear industries have been widely used . Rich resources of tungsten , tungsten- rhenium thermocouples cheap, can be partially substituted precious metal thermocouples , it is the high-temperature test promising field of temperature materials . Easily oxidized tungsten- rhenium thermocouples , suitable for hydrogen in an inert or dry use , or dense protective tube isolated in order to use it with oxygen . Carbon-containing atmosphere can not be used ( as in the use of hydrocarbon-containing atmosphere , the temperature exceeds 1000 ℃ i.e. by corrosion) . Tungsten or tungsten- rhenium in a carbonaceous atmosphere is easy to form a stable carbide , that reduce the sensitivity and cause brittle fracture, in the case of the presence of hydrogen , is accelerated carbonation .

HNWL Tungsten Rhenium Thermocouples Type Description :

HNWL tungsten rhenium thermocouples divided into three categories , one category is used in fine ceramic protection tube , the other is pure molybdenum protection tube, then a class is a tungsten protective tube . Ceramic tube specifications: diameter Ф8, Ф10, Ф12, Ф14, Ф16, length 300 ~ 1100mm, such thermocouples work atmosphere free from the restrictions in any atmosphere, long-term use , temperature range is 0 ~ 1800 ℃ the ; molybdenum and tungsten tube tube specifications: diameter Ф6, Ф8, Ф10mm, length 500 ~ 700mm, this thermocouple only in a vacuum , reducing or inert gas environment and long-term work , molybdenum tube preferably in 1800 ℃ long-term use at temperatures below , short-term use temperatures up to 2000 ℃; as tungsten tube is able to work at 2100 ℃ long-term , it is difficult to process resulting in the price is very expensive.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Oxidation of Tungsten Rhenium Thermocouples

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 13:51

- Hits: 1849

Oxidation of tungsten rhenium thermocouples used to solve the physical structure of tungsten rhenium thermocouple temperature oxidation problems . Which is characterized by high temperature oxidation. In oxidation, reduction , or alternating between the two atmospheres , and the price is cheap, only platinum and rhodium 1/ 2 to 1/ 4 . Thus, in 1996 a national new product certification, and obtained national patent.

The products are mainly used in metallurgy , chemical industry, refractory furnace and coal gasification or sulfur recovery unit for temperature measurement , the main technical indicators :

Model No indexing ASTM

Indexing Tolerance Measuring range (℃) Applicable atmosphere

WR □ W-134 □ WRe3-WRe25

(W3) D ± 1.0% t 0 ~ 1700

Oxidation, reduction , or both alternately

WR □ W-13525 WRe5-WRe26

(W5) C

WR □ W-13530

Varieties and specifications

Type protective tube

Structure Diameter (mm) Material

WR W3 W-134 □ Single Tube 8 ~ 16 corundum

WR W3 W-13525 Double

Composite pipe materialized

Structure 16 ( inside ) × 25 ( outside ) corundum

WR W3 W-13525 12 ( inside ) × 25 ( outside ) corundum ( internal )

+ SiC ( outside )

WR W3 W-13530 16 ( inside ) × 30 ( outside ) corundum ( internal )

+ SiC ( outside )

WR W3 W-13530 16 ( inside ) × 30 ( outside ) corundum ( internal ) +

Cermet ( outside )

● Protection tube diameter and length specification table (mm)

Φ16 ( single tube ) Φ20

Length L is set deep l length L is set deep l

300 150 400 250

350 200 450 300

400 250 550 400

450 300 650 500

550 400 900 750

650 500 1150 1000

900 750 1650 1500

1150 1000 2150 2000

Note : Metal ceramic tube up to 500 l .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten-Rhenium Thermocouples Definition and Development History

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 13:46

- Hits: 1838

Tungsten- rhenium thermocouples is high temperature thermocouples. It has the potential of a linear relationship between temperature , thermal stability , reliable, cheap, etc. . And display instrument for direct measurement of liquids , steam and gases such as temperature. It can partially substitute platinum-rhodium thermocouple as high metallurgical industry , high-temperature electronic thermoelectric systems and space vehicle structural engineering , ultra-high temperature nuclear reactors measurement tools .

Tungsten- rhenium thermocouples for temperature dependence of thermopower meet ZBN05003-88 indexing table , equivalent ASTME696-84 standards. In a vacuum , reducing , inert atmosphere , at 0 ~ 2300 ℃ range. The use of special protective tube tungsten rhenium even can at 1600 ℃ under oxidizing atmosphere, long-term use , its price is lower than the platinum- rhodium thermocouple .

Tungsten- rhenium thermocouples is 1931 by Goedecke ( Ge virtues g ) first developed out at 60 to 70 years to develop the most successful refractory metal thermocouples. Tungsten- rhenium thermocouple is characterized by: a high melting point hot wire (3300 ℃), vapor pressure, easily oxidized ; in a non- oxidizing atmosphere, good chemical stability. Emf , high sensitivity , the most important is cheap. Tungsten- rhenium thermocouples is 60 years developed a high temperature thermocouple, a W / (W-26Re), (W-3Re) / (W-25Re), (W-5Re) / (W-26Re) and ( W-5Re) / (W-20Re) and so on. Long-term use temperature of 2000 ~ 2400 ℃, short-term use up to 3000 ℃. In the low-temperature thermocouples , (Au-2.1Co) / Cu thermocouple, the 10K or more thermoelectric power greater than 10μV / K; gold contains trace amounts ( about 0.07 atomic percent ) alloy of iron and nickel-chromium alloy composition thermocouple, at liquid helium temperature (4K) thermoelectric power greater than 10μV / K, all the better . (Pt-0.1Mo) / (Pt-5Mo), (Pt-1Mo) / (Pt-5Mo) and tungsten , and 0.5 to 1 ( atomic% ) alloy of osmium and rhenium tungsten alloy thermocouples in nuclear irradiation conditions. In addition to metallic materials, graphite and other non-metallic materials, refractory compounds can also be used as high temperature thermocouples. The advantage of such materials are high melting point , high temperature stability, high thermal potential and thermoelectric power , etc. ; drawback is brittle materials , graphite is easy to absorb moisture and changes in thermal resistance , poor reproducibility , but also in research and development into . Such thermocouples with carbon / graphite , graphite / carbide , carbide / carbide .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten-Rhenium Thermocouple Applications

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 13:43

- Hits: 1899

1, Tungsten- rhenium thermocouples metallurgical industry , powder metallurgy applications

metallurgy products usually in reducing atmosphere such as hydrogen production , the working temperature 1000 ~ 1800 ℃. Just using sintered corundum tube or pipe , materialized oxidation of tungsten rhenium thermocouple powder metallurgy plant in Xiangtan and other applications for many years.

2, Tungsten- rhenium thermocouples VN , manganese nitrogen, boron carbide and chromium -nitrogen alloy Si3N4 powder production application

currently about VN , nitrogen alloy chromium , manganese alloy production and nitrogen Si3N4 powder production process control, more mining materialized oxidation of tungsten rhenium thermocouples, 2003 in the amount of 500 above , access to users.

3, Tungsten- rhenium thermocouples nonferrous metallurgy application

application

in lead smelting process, in order to lead slag can be well separated , often using electric front bed of new technology, the sensor must be exposed to high temperatures , corrosive media. Testing environment is extremely harsh , resulting in a very short life platinum-rhodium thermocouple ( only two weeks or so ) , materialized oxidation of tungsten rhenium thermocouples can not only replace expensive platinum-rhodium thermocouple, but life is doubled.

4, Tungsten- rhenium thermocouples materialized oxidation of tungsten rhenium thermocouples application < / span>

in Chemical Plant pyrolysis furnace using tungsten- rhenium thermocouples replace platinum and rhodium even, at 1400 ℃ under a reducing atmosphere , the use of composite alumina tube to get good results.

5, Tungsten- rhenium thermocouples 1800 ℃ -2000 ℃ high temperature application

At temperatures above 1800 ℃ under the conditions currently only uses tungsten rhenium thermocouples. I am using the BN insulation, sintered tungsten tube , successfully used in 1800 ℃ -2000 ℃ vacuum furnace, there are many users.

6,Tungsten- rhenium thermocouples liquid steel temperature measurement application < span style = "font-size: 12px">

Under vacuum conditions , the use of metal-ceramic protective tube (Φ10 × 140 ~ 190) tungsten rhenium thermocouple batch temperature of molten steel in-line measurement , in order to meet the needs of a vacuum metallurgical production process .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten-Rhenium Thermocouples and Temperature Tolerance Overview

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 13:41

- Hits: 1908

A tungsten rhenium thermocouples overview

Tungsten- rhenium thermocouples is high temperature thermocouples. It has the potential of a linear relationship between temperature , thermal stability , reliable, cheap, etc. . And display instrument for direct measurement of liquids , steam and gases such as temperature. It can partially substitute platinum-rhodium thermocouple as high metallurgical industry , high-temperature electronic thermoelectric systems and space vehicle structural engineering , ultra-high temperature nuclear reactors measurement tools .

Tungsten- rhenium thermocouples for temperature dependence of thermopower meet ZBN05003-88 indexing table , equivalent ASTME696-84 standards. In a vacuum , reducing , inert atmosphere , at 0 ~ 2300 ℃ range. The use of special protective tube tungsten rhenium even can at 1600 ℃ under oxidizing atmosphere, long-term use , its price is lower than the platinum- rhodium thermocouple .

Second, tungsten rhenium thermocouple temperature tolerance tungsten rhenium thermocouples

Temperature 1300 ~ 1700 ℃ Tolerance 0.5% | t |

0 ~ 2300 ℃ Tolerance 1% | t |

Third, temperature insulation resistance : tungsten rhenium thermocouples in the ambient air temperature of 20 ± 15 ℃, relative humidity less than 85% , the heat between the electrode and the outer protection tube insulation resistance should be greater than 100MΩ.m.

Forth , tungsten rhenium 3/ 25 tungsten rhenium thermocouple protection tube outer

( 1 ) silicon carbide tube (Sic) at 1600 ℃ oxidizing atmosphere using the following

( 2 ) molybdenum disilicide tube (Mosi2) at 1600 ℃ under air and some corrosive atmospheres ( supply agreement )

( 3 ) molybdenum tube (Mo) at 2300 C in vacuum using the following ( supply agreement )

( 4 ) tantalum tube (Ta) at 2300C using the following vacuum ( supply agreement )

Fifth , tungsten rhenium thermocouple indexing are: tungsten rhenium 3 - 25 tungsten rhenium , tungsten, rhenium 5 - tungsten- rhenium 26.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Standardized Tungsten Rhenium Thermocouple Wire

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2013 13:38

- Hits: 1936

Standardization of tungsten rhenium thermocouples are tungsten rhenium 3 - tungsten- rhenium 25 (D -type ) and tungsten rhenium 5 - tungsten rhenium 26 (C -type ) of two types, corresponding indexing are: tungsten rhenium 3 - tungsten and tungsten- rhenium 25 rhenium 5 - tungsten rhenium 26.

Tungsten- rhenium thermocouple wire quality performance standards described :

1 , Delivery specifications for diameter 0.1 ~ 0.5mm, diameter tolerance of ± 0.01mm;

2 , Even silk smooth surface, no oxidation, no bending, no glitches, mezzanine and splitting , allowing a small scratches , dents and a few spots ;

3 , According to the provisions sampling sampling test, the positive wire ( low rhenium ) and negative wire ( high rhenium ) at 1200 ℃ uneven thermal emf when no more than 80 microvolts (t0 = 0 ℃, namesake electrode method );

4 , At 20 ~ 30 ℃ ambient temperature , thermocouple wire diameter 5 times its own diameter shaft 5 laps wound surface without cracks, dual wire bent without breaking ;

5 , The temperature thermoelectric properties verification point : 100 ℃ (± 1 ℃), 1000 ℃ (± 10 ℃), 1200 ℃ (± 10 ℃), 1400 ℃ (± 10 ℃), 1600 ℃ (± 10 ℃), 2000 ℃ (± 10 ℃), or in consultation with users selected test temperature points ;

6 , Each batch furnaces have passed the type test .

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com;sales@xiamentungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com